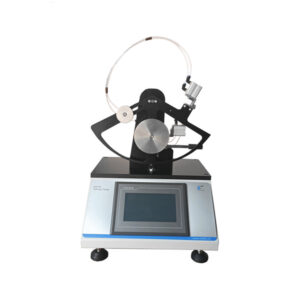

Introduction Internal Bond Tester

Các Máy kiểm tra liên kết bên trong BGT-01 is an advanced instrument designed to measure the energy required to rapidly delaminate a paper or board sample in the Z-direction. This test simulates the rapid impacts and shock loads that paper and board products may undergo during processes such as printing or conversion. The Internal Bond Tester uses a pendulum with a defined mass and velocity to initiate rupture, making it an ideal tool for assessing the material’s resistance to internal stresses.

The BGT-01 is perfect for testing a variety of paper and board materials, including single- and multi-layer paper, coated sheets, and boards laminated with synthetic polymer films. It is particularly suitable for materials subjected to Z-direction rapid impacts, such as packaging, printing, and other industrial applications where durability is critical.

Test Methods: ISO 16260 and Standards

Tiêu chuẩn ISO 16260: The International Standard for Internal Bond Testing

Tiêu chuẩn ISO 16260 specifies the test method for measuring the internal bond strength of paper and paperboard materials. This standard defines a procedure for conducting tests where a pendulum impact is used to delaminate the sample, evaluating the material’s strength under rapid, localized stress. By simulating real-world conditions in which paper and board are subjected to shock loads, Tiêu chuẩn ISO 16260 helps ensure that materials are durable and reliable.

- Quy trình kiểm tra: The internal bond strength is measured by releasing a pendulum with a fixed mass, which impacts the sample at a specified velocity, initiating delamination in the Z-direction.

- Sự liên quan: This standard is crucial in ensuring that paper and board materials are capable of withstanding impacts encountered during production, packaging, and transportation. Compliance with Tiêu chuẩn ISO 16260 is essential for manufacturers in the paper, packaging, and related industries to ensure product performance and quality.

Additional Relevant Standards

- TAPPI T569: A standard developed by the Technical Association of the Pulp and Paper Industry that focuses on the delamination of paperboard materials when subjected to controlled pendulum impact forces.

- GB/T 26203: A Chinese standard that defines the internal bond test for paper and board materials, aligning with international testing protocols.

- QB/T 5558: A Chinese standard that governs internal bond strength testing for paper and cardboard materials, ensuring they meet required performance characteristics for packaging.

Features and Benefits of the BGT-01 Internal Bond Tester

- Automatic Pendulum Release: The BGT-01 Internal Bond Tester is equipped with an automatic pendulum release mechanism that ensures consistent and repeatable test results every time. This feature enhances accuracy and reliability.

- High Resolution and Precision: The instrument features a data acquisition resolution of 0.001 lbf/in², powered by a high-precision 5000-pulse encoder. This allows for detailed measurements of the internal bond strength, ensuring that even slight differences in material performance can be detected.

- Self-Calibration Tool: The BGT-01 Internal Bond Tester comes with a special 5-level calibration tool kit (additional accessory), allowing easy calibration to maintain optimal performance and accuracy over time.

- Flexible Unit Switching: Các Internal Bond Tester offers versatility with the ability to switch between units of measurement, including J/M² and lbf/in², making it adaptable to different industry requirements.

- Giao diện thân thiện với người dùng: The 5.0-inch color touchscreen interface is intuitive, displaying real-time test data, and allowing for easy navigation through test settings, results, and operational modes.

- Advanced Software for Data Processing: Optional computer connection software is available for more advanced data processing, analysis, and report generation. This provides an easy way to manage test data, document results, and perform further analysis for quality assurance or R&D purposes.

- Modular Thermal Printer: Integrated into the BGT-01 is a thermal printer that allows users to print test results immediately. This modular feature makes it easier to record and share test outcomes without needing an external device.

Ứng dụng

- Ngành công nghiệp bao bì: The BGT-01 is widely used to test materials such as case boards, grey boards, ivory boards, and synthetic polymer-coated papers. These materials must exhibit high internal bond strength to withstand the mechanical stresses encountered during packaging, storage, and transportation.

- Paper Manufacturing: Ideal for assessing the quality and durability of paper materials, the BGT-01 is suitable for both single-layer and multi-layer paper, as well as coated sheets, commonly used in various paper products and packaging.

- Textiles and Medical Device Packaging: The Internal Bond Tester is used in industries where paper and board materials must demonstrate resistance to rapid impacts, such as packaging materials for medical devices or textiles.

- Quality Control and Assurance: Quality assurance labs rely on the BGT-01 for consistent testing and evaluation of internal bond strength, ensuring that products meet industry standards and customer requirements.

Các thông số chính

| Kích thước mẫu | 25.4*25.4mm (Five Groups) |

| Sample Holding Force | 0~400N (Adjustable) |

| Sample Pressure Range | 0~65kg/cm² |

| Impact Angle | 90° |

| Nghị quyết | 0.001lbf/in² |

| Measuring Range | A: 0-500J/M² |

| B: 500~1000J/M² | |

| C: 1000~1500J/M2 | |

| Lỗi chỉ định | A: ±1J/M² B: ±2J/M² C: ±5J/M² |

| Unit | lb-ft/in², J/M² |

| Kích thước | 450m×380cm×600mm |

| Quyền lực | Điện áp xoay chiều 220V 50Hz |

| Sample cutter specification | |

| Sampling Size | 25.4mm*140mm |

| Parallelism Of Two Long Sides | ≤0.015mm |

| Sampling Thickness | (0.05~1.2) mm |

| Kích thước | About 580*150*620mm |

| Cân nặng | About 15kg |

Benefits of Using the BGT-01 Internal Bond Tester

- Độ chính xác và độ tin cậy: With its high precision and advanced features, the BGT-01 ensures accurate and reproducible results, allowing manufacturers to meet stringent industry standards.

- Compliance with ISO 16260: The BGT-01 fully complies with Tiêu chuẩn ISO 16260, making it an essential tool for those needing to meet international testing standards.

- Versatile and Easy to Use: Whether for R&D, quality control, or production testing, the BGT-01 offers a versatile and user-friendly experience, with the ability to handle a range of paper and board materials.

- Improved Product Quality: By ensuring that materials meet internal bond strength requirements, the BGT-01 helps improve the quality and durability of paper, board, and packaging products.

Why Choose the BGT-01 Internal Bond Tester?

- For Paper and Packaging Manufacturers: The BGT-01 ensures that materials have the internal strength needed to withstand rapid impacts during handling, processing, and transportation. This is critical for packaging products that must perform under stressful conditions.

- For Research and Development: R&D teams working in paper manufacturing or materials science will find the BGT-01 essential for accurately measuring the internal bond strength of new paper and board formulations.

- For Quality Control and Assurance: With its ease of use, automated features, and high precision, the BGT-01 is the ideal choice for quality control labs to maintain consistency in product quality and regulatory compliance.

Phần Câu hỏi thường gặp

- What is the purpose of the Internal Bond Tester?

- The Internal Bond Tester measures the energy required to delaminate paper or board samples in the Z-direction. It simulates shock loads and impacts to evaluate the material’s durability.

- How is the BGT-01 different from other internal bond testers?

- The BGT-01 offers automatic pendulum release, high resolution (0.001 lbf/in²), self-calibration, and a color touchscreen interface. These features ensure precision, reliability, and ease of use.

- Is the BGT-01 compliant with international standards?

- Yes, the BGT-01 complies with Tiêu chuẩn ISO 16260, TAPPI T569, and other industry standards, ensuring it meets the quality and performance criteria required for various industries.

- Can I use the BGT-01 for testing coated or laminated materials?

- Yes, the BGT-01 is suitable for testing a wide variety of paper and board materials, including coated and laminated products like synthetic polymer films.

- Does the BGT-01 have software for data analysis?

- Yes, the BGT-01 can be connected to optional computer software, allowing for detailed data processing, analysis, and report generation, perfect for quality control or research purposes.