Introduction to Heat Seal Testing Machines

MỘT Heat Seal Testing Machine is a crucial device used in the packaging industry to evaluate the heat-sealing properties of various materials. These materials may include films, laminates, and other flexible barrier components. The heat seal strength and integrity are vital for ensuring that packaging provides reliable protection for products such as food, pharmaceuticals, electronics, and more. Inaccurate or weak seals can compromise the product’s quality, safety, and shelf life, which is why the heat seal tester plays a critical role in quality assurance.

The machine works by simulating the conditions under which heat seals are formed during the packaging process. By applying a controlled combination of heat, pressure, and time, manufacturers can determine the optimal conditions for achieving strong, durable seals. This process helps in fine-tuning the sealing parameters, ensuring the packaging is consistent and reliable.

Understanding ASTM F2029-16 (2021): Standard Practices for Making Laboratory Heat Seals

Tiêu chuẩn ASTM F2029-16 (2021), titled Thực hành tiêu chuẩn để tạo lớp niêm phong nhiệt trong phòng thí nghiệm nhằm xác định khả năng niêm phong nhiệt của vật liệu rào cản linh hoạt được đo bằng độ bền của lớp niêm phong, is a fundamental standard for heat seal testing. This standard defines the laboratory procedures for creating heat seals and evaluating their strength. It ensures that the heat seal testing is performed under precise, controlled conditions to produce accurate, repeatable results.

Các test methods outlined in Tiêu chuẩn ASTM F2029 focus on determining the heat sealability of materials by applying specific temperature, pressure, and dwell time. The standard helps manufacturers understand the sealing characteristics of flexible barrier materials, including how they perform under different sealing conditions. This is essential for ensuring the material’s integrity and its ability to protect contents from external factors such as moisture, air, and contaminants.

Gradient Heat Sealer: Advanced Technology for Precision Testing

MỘT Gradient Heat Sealer is an advanced heat seal testing machine that offers the ability to create a controlled temperature gradient across the sealing area. This feature distinguishes it from traditional heat sealers, which typically operate at a single temperature. The term “gradient” refers to the machine’s capacity to simulate real-world sealing conditions where temperature variations can occur across the sealing surface.

Các Gradient Heat Sealer enables manufacturers to run multiple tests at different temperatures simultaneously, significantly reducing waiting times between tests. This multi-station capability makes the machine highly efficient, especially when testing materials with varying heat seal requirements. By testing at different temperatures at once, manufacturers can quickly determine the best sealing conditions for different materials, improving overall productivity.

Key Benefits:

- Tăng hiệu quả: Simultaneous testing at different temperatures reduces the overall testing time.

- Enhanced Precision: The gradient feature ensures a more accurate representation of real-world sealing conditions, providing better insight into material behavior under varied sealing conditions.

- Customizable Settings: The machine can be adjusted to accommodate various material types, temperatures, and pressures, making it versatile for different industries and testing needs.

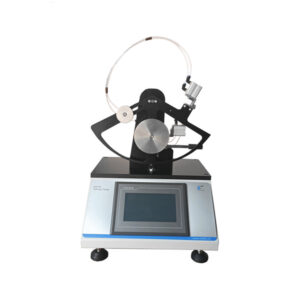

Technical Features of the Heat Seal Testing Machine (GHS-02 Gradient Heat Seal Tester)

Các Máy kiểm tra độ kín nhiệt GHS-02 is equipped with several cutting-edge features that ensure accurate, reliable, and efficient testing:

- Điều khiển PLC & Màn hình cảm ứng HMI: The machine’s advanced PLC control unit Và HMI touchscreen interface allow for easy customization of settings and real-time monitoring, ensuring precise control over temperature, pressure, and sealing time.

- Dual Heating Jaws: Both the upper and lower sealing jaws are independently heated, which eliminates heat loss and ensures a consistent temperature throughout the sealing process.

- Bộ điều khiển nhiệt độ PID: Các PID temperature controller provides optimal heating management, ensuring that the temperature remains stable and accurate during testing.

- Proximity and Pressure Sensors: These sensors ensure accurate control of the sealing pressure and dwell time, helping to achieve uniform seals.

- Guided Sealing Bar: MỘT three-way guided sealing bar ensures consistent sealing pressure, which is critical for uniform and strong seals.

- User Safety Features: The GHS-02 is designed with user protection in mind, including an anti-scald front cover, a manual foot switch, and other safety features to ensure the safety of operators during testing.

- Tùy chọn tùy chỉnh: The machine offers customizable seal jaw dimensions, sealing surface patterns, and more to accommodate various testing needs.

- Gradient Temperature Customization: The machine can be configured to achieve different gradient temperatures, allowing for greater testing flexibility.

- RS232 Port for Data Connectivity: Các Cổng RS232 and optional professional software allow for seamless data transfer, making it easier to analyze and store test results.

Test Process and Workflow

The test process using the Heat Seal Testing Machine is straightforward yet precise:

- Place the Sample: A sample of the material to be tested is placed between two parallel, heated sealing jaws with flat surfaces.

- Adjust Settings: The user sets the desired temperature, pressure, and sealing time based on the material and the intended sealing conditions.

- Seal the Sample: Once the required temperature is reached, the upper sealing jaw, driven by a gas cylinder, is lowered to apply a specified pressure on the sample for the designated time.

- Return and Evaluation: After the preset sealing time ends, the upper jaw returns to its original position, and the sample is removed for evaluation.

Main Parameters of the Heat Seal Testing Machine

Các Máy kiểm tra độ kín nhiệt GHS-02 comes with a set of precise parameters to ensure accurate results:

| Nhiệt độ niêm phong | Nhiệt độ môi trường ~ 250℃ |

| Temp. Gradient | ≤20℃ |

| Độ lệch | ±0,2℃ |

| Thời gian niêm phong | 0.1S~9999H |

| Áp suất niêm phong | 0,15~0,7MPa |

| Seal Jaws(mm) | U:40*10 5PCS/L:330 1PCS |

| Gas Input | 0.7 MPa with Ф6 mm Pipe |

| Quyền lực | Điện áp xoay chiều 220V 50Hz |

Standards Compliance and Certifications

Các Heat Seal Testing Machine hoàn toàn tuân thủ ASTM F2029-16 (2021), ensuring that the machine meets the required industry standards for heat seal testing. This certification guarantees that the machine produces reliable, accurate results that are consistent with the most widely recognized heat sealing standards. Manufacturers can trust that the GHS-02 Gradient Heat Seal Tester provides accurate measurements that help ensure the quality and reliability of their packaging.

Why Choose the GHS-02 Gradient Heat Seal Tester

- Hiệu quả: Test multiple samples at varying temperatures simultaneously, reducing overall testing time and increasing productivity.

- Precision: Achieve highly accurate test results with customizable parameters and advanced temperature control.

- Độ tin cậy: Compliance with Tiêu chuẩn ASTM F2029 ensures that your testing adheres to industry standards for heat seal strength and integrity.

- Tùy chỉnh: Tailor the machine’s settings and features to suit your unique testing needs, from seal jaw dimensions to sealing pressure.

Các Heat Seal Testing Machine is an essential tool for manufacturers in the packaging industry, ensuring that their products are sealed with optimal strength and integrity. Whether you’re packaging food, pharmaceuticals, or electronics, the GHS-02 Gradient Heat Seal Tester provides the precision and efficiency you need to ensure the highest quality seals. With its advanced technology, compliance with Tiêu chuẩn ASTM F2029, and customizable settings, this machine is the ideal choice for companies looking to enhance their packaging quality control processes.