Ointment refers to a semi-solid external preparation with a certain consistency made by uniformly mixing a drug with a suitable base. The ointment is contained in a polyethylene/aluminum/polyethylene composite tube. In order to ensure the safety and stability of the drug during circulation and use, the drug packaging material standard sets some requirements for the physical properties of the ointment tube packaging. In the following, we will introduce the performance requirements and test methods of polyethylene/aluminum/polyethylene composite pharmaceutical ointment tubes in combination with the requirements of the national pharmaceutical packaging material standards.

Reference standard (part):

YBB00252005-2015 Polyethylene/aluminum/polyethylene compound medicinal ointment tube

Compressive strength

Take an appropriate amount of sample, tighten the tube cap with a torque of 30~90N cm, add compressed air from the end of the tube, the air pressure is 0.2MPa, put it in a water bath at 20°C±2°C, keep pressurizing for 30 seconds, no rupture, and weld There should be no air bubbles at the seams. .

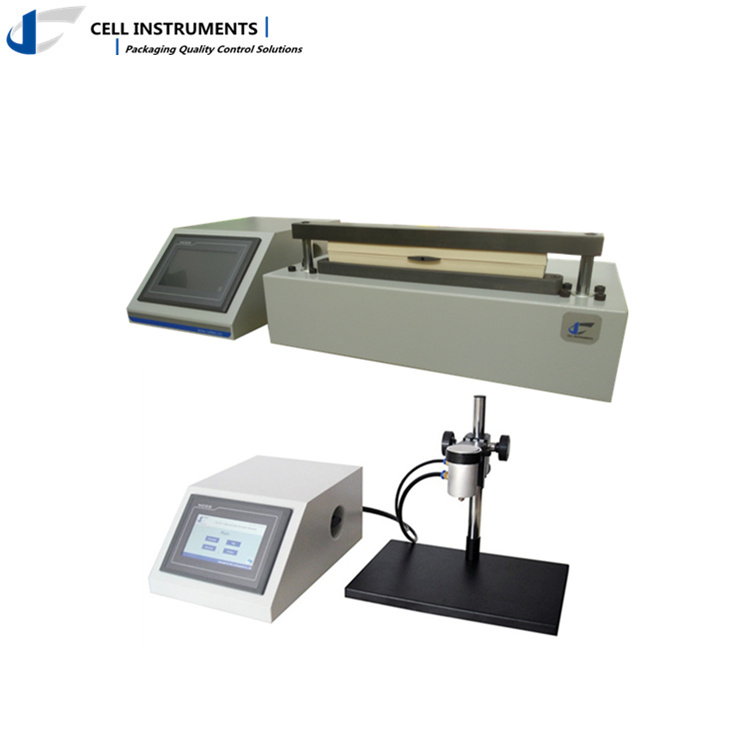

Peel strength between inner layer and sub-inner layer

Take an appropriate amount of samples and measure them according to the peel strength test method (YBB00102003-2015). The average value of the longitudinal and transverse peel strengths should not be less than 5.0N/15mm.

Test requirements for peel strength in YBB00102003-2015 peel strength test method:

Clamp both ends of the sample in the upper and lower furniture of the testing machine, so that the longitudinal axis of the stripped part of the sample coincides with the center line of the upper and lower clamps, and the tension is appropriate. During the test, the unpeeled part and the tensile direction are T-shaped, the test speed is 300mm/min±30mm/min, and the peeling force curve during the peeling process of the sample is recorded.

Tensile strength

Take the composite pipe with the same batch number, and measure it according to the method for measuring tensile properties (YBB00112003-2015). Type II samples are used, and the test speed is 100 mm/min±10mm/min. Record the load when the first layer of material breaks, which is the tensile strength. tensile strength. Both vertical and horizontal shall not be lower than 16.0MPa.