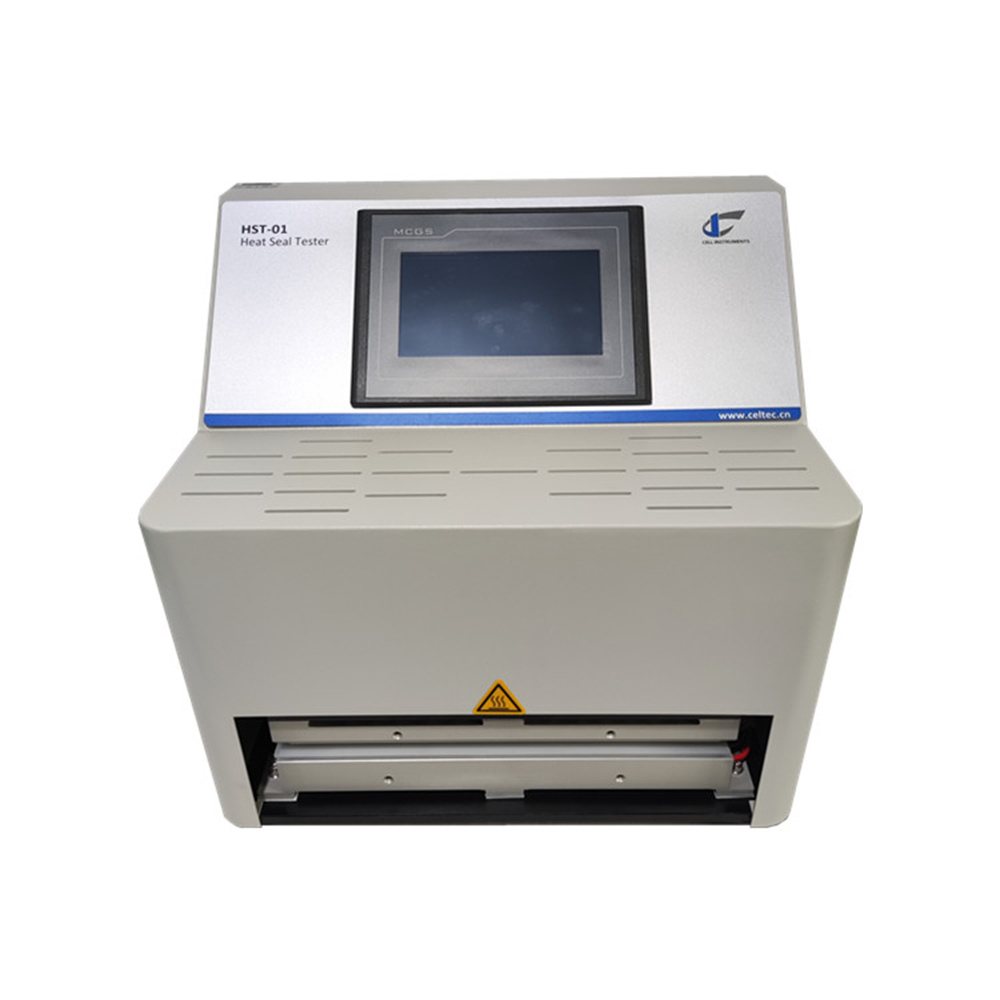

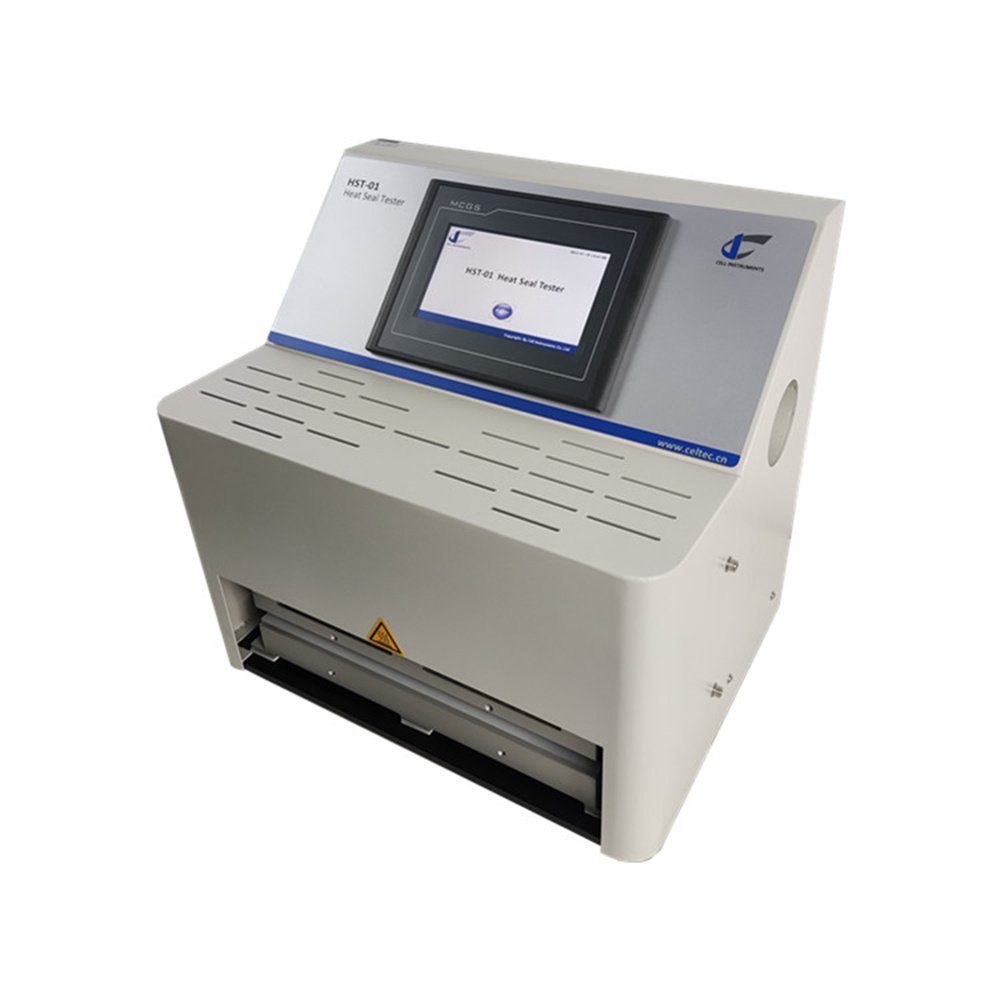

Giới thiệu về Máy kiểm tra độ kín nhiệt HST-01

Các Máy kiểm tra độ kín nhiệt HST-01 là một thiết bị cấp phòng thí nghiệm được thiết kế để đánh giá khả năng hàn nhiệt của vật liệu chắn linh hoạt, bao gồm màng, vật liệu nhiều lớp, polyme và vật liệu composite. Thiết bị đa năng này mô phỏng chính xác quá trình hàn nhiệt bằng cách kiểm soát ba thông số quan trọng: thời gian, nhiệt độ và áp suất. Vai trò chính của nó là đảm bảo rằng các lớp niêm phong trong bao bì mềm đáp ứng các tiêu chuẩn về độ bền và tính toàn vẹn, góp phần đảm bảo an toàn sản phẩm, thời hạn sử dụng và dễ sử dụng.

Ứng dụng của Máy kiểm tra độ kín nhiệt HST-01

Máy kiểm tra độ kín nhiệt HST-01 rất cần thiết trong nhiều ngành công nghiệp, bao gồm:

- Bao bì: Đánh giá khả năng hàn nhiệt cho bao bì thực phẩm, dược phẩm và y tế.

- Thiết bị y tế: Đảm bảo tính toàn vẹn của hàng rào vô trùng trong túi và vỉ thuốc y tế.

- Hàng tiêu dùng: Kiểm tra niêm phong trên các sản phẩm hóa chất hàng ngày và các mặt hàng chăm sóc cá nhân.

- Điện tử: Đánh giá bao bì bảo vệ cho các linh kiện điện tử.

- Chất kết dính và vật liệu tổng hợp: Đo hiệu suất hàn nhiệt của các vật liệu đặc biệt.

Việc hàn nhiệt hiệu quả đảm bảo sản phẩm luôn an toàn, không bị nhiễm bẩn và dễ tiếp cận, nâng cao chất lượng tổng thể và sự hài lòng của người tiêu dùng.

ASTM F2029 và tầm quan trọng của nó trong thử nghiệm hàn nhiệt

Tổng quan về Tiêu chuẩn ASTM F2029

Các Tiêu chuẩn ASTM F2029-16 (2021) tiêu chuẩn, có tiêu đề Thực hành tiêu chuẩn để tạo lớp niêm phong nhiệt trong phòng thí nghiệm nhằm xác định khả năng niêm phong nhiệt của vật liệu rào cản linh hoạt được đo bằng độ bền của lớp niêm phong, phác thảo các phương pháp được sử dụng để sản xuất và đánh giá các lớp niêm phong nhiệt trong vật liệu đóng gói linh hoạt. Tiêu chuẩn này đảm bảo rằng các lớp niêm phong nhiệt nhất quán và đáng tin cậy trong nhiều ứng dụng khác nhau.

Phương pháp thử nghiệm

ASTM F2029 chỉ định các điều kiện được kiểm soát để tạo ra mối hàn nhiệt, tập trung vào:

- Nhiệt độ: Duy trì mức nhiệt chính xác trong quá trình niêm phong.

- Thời gian: Đảm bảo độ kín được hình thành trong thời gian nhất quán.

- Áp lực: Sử dụng lực đồng đều để tạo ra liên kết chắc chắn.

Sau đó, độ bền của lớp niêm phong được đánh giá bằng các phương pháp như:

- Kiểm tra rò rỉ không khí.

- Sự thẩm thấu của thuốc nhuộm.

- Kiểm tra trực quan để phát hiện tính liên tục và khuyết tật.

Ý nghĩa của việc tuân thủ

Việc tuân thủ ASTM F2029 đảm bảo rằng kết quả thử nghiệm có thể tái tạo được và đáp ứng các tiêu chuẩn của ngành, tạo dựng niềm tin vào hiệu suất và chất lượng sản phẩm.

Tính năng kỹ thuật của máy kiểm tra độ kín nhiệt HST-01

HST-01 được thiết kế với các tính năng tiên tiến đảm bảo thử nghiệm hàn nhiệt chính xác và có thể lặp lại:

- Kiểm soát độ chính xác:

- Phạm vi nhiệt độ: Nhiệt độ môi trường đến 300°C, với độ lệch ±0,2°C.

- Thời gian niêm phong: Có thể điều chỉnh từ 0,1 giây đến 9999 giây.

- Phạm vi áp suất: 0,15 đến 0,7 MPa, đảm bảo lực tác dụng đồng đều.

- Thiết kế hiệu suất cao:

- Hàm nhôm kép được gia nhiệt giúp giảm thiểu thất thoát nhiệt và duy trì nhiệt độ ổn định.

- Thanh niêm phong dẫn hướng ba hướng đảm bảo phân phối áp suất đồng đều.

- MỘT Bộ điều khiển nhiệt độ PID đảm bảo gia nhiệt nhanh chóng và chính xác.

- Hoạt động thân thiện với người dùng:

- Điều khiển PLC với giao diện màn hình cảm ứng HMI trực quan cho hoạt động liền mạch.

- Kích hoạt bằng tay hoặc bằng chân để linh hoạt hơn trong quá trình thử nghiệm.

- Các tính năng an toàn, bao gồm nắp chống bỏng phía trước, ưu tiên bảo vệ người dùng.

- Tùy chọn tùy chỉnh:

- Hàm kẹp có thể tùy chỉnh để phù hợp với nhiều hình dạng, kích thước và hoa văn khác nhau.

- Không bắt buộc Cổng COM RS 232 và phần mềm phân tích và báo cáo dữ liệu.

Quy trình thử nghiệm của máy kiểm tra độ kín nhiệt HST-01

Quy trình thử nghiệm hàn nhiệt thực hiện theo các bước sau:

- Chuẩn bị mẫu: Đặt vật liệu thử nghiệm giữa hai hàm hàn song song được làm nóng.

- Cài đặt tham số: Cài đặt nhiệt độ, áp suất và thời gian niêm phong mong muốn.

- Niêm phong:Hàm trên, được điều khiển bởi bình khí, sẽ tạo áp suất lên mẫu trong khoảng thời gian đã cài đặt.

- Hoàn thành:Sau thời gian cài đặt trước, hàm sẽ trở về vị trí ban đầu, hoàn tất quá trình.

- Sự đánh giá:Mẫu đã niêm phong được đánh giá về độ bền và tính liên tục bằng các phương pháp như thử nghiệm rò rỉ không khí và thử nghiệm thấm thuốc nhuộm.

Đánh giá và phân tích về Heat Seal

Chất lượng con dấu được đánh giá thông qua:

- Sức mạnh của con dấu: Đo lực cần thiết để phá vỡ lớp niêm phong.

- Tính liên tục và toàn vẹn: Xác định các khuyết tật như rò rỉ hoặc điểm yếu.

- Kỹ thuật tiên tiến:Thâm nhập vi khuẩn và kiểm tra trực quan cho các ứng dụng có độ chính xác cao.

Những đánh giá này đảm bảo rằng bao bì đáp ứng được các yêu cầu về hiệu suất chức năng và mong đợi của người tiêu dùng.

Thông số chính và thông số kỹ thuật

| Nhiệt độ niêm phong | Nhiệt độ môi trường ~ 300℃ |

| Độ lệch | ±0,2℃ |

| Thời gian niêm phong | 0,1 giây ~ 9999 giây |

| Áp suất niêm phong | 0,15~0,7MPa |

| Hàm hải cẩu | 330*10mm Dài*Rộng |

| Áp suất khí | 0,7MPa |

| Kích thước cổng | Ống PU Ф6 mm |

| Quyền lực | Điện áp xoay chiều 220V 50Hz |

Tại sao nên chọn máy kiểm tra độ kín nhiệt HST-01?

HST-01 cung cấp độ chính xác, độ ổn định và độ an toàn vô song, khiến nó trở thành lựa chọn lý tưởng cho các phòng thí nghiệm và các cơ sở kiểm soát chất lượng. Tuân thủ Tiêu chuẩn ASTM F2029 đảm bảo kết quả đáng tin cậy, đạt tiêu chuẩn công nghiệp, giúp nhà sản xuất duy trì chất lượng và hiệu suất sản phẩm.

Câu hỏi thường gặp

- Mục đích của máy kiểm tra độ kín nhiệt là gì?

- Máy kiểm tra độ kín nhiệt đánh giá độ bền và tính toàn vẹn của vật liệu đóng gói mềm, đảm bảo tính an toàn và hiệu suất của sản phẩm.

- Tại sao ASTM F2029 lại quan trọng?

- ASTM F2029 cung cấp các thông lệ chuẩn hóa để sản xuất và thử nghiệm gioăng chịu nhiệt, đảm bảo kết quả nhất quán và có thể lặp lại trong nhiều ngành.

- Những vật liệu nào có thể được thử nghiệm bằng HST-01?

- HST-01 có thể thử nghiệm màng phim, vật liệu cán mỏng, polyme, vật liệu tổng hợp và các vật liệu chắn linh hoạt khác.

- HST-01 đảm bảo độ kín chính xác như thế nào?

- Hệ thống này sử dụng khả năng kiểm soát chính xác nhiệt độ, thời gian và áp suất, kết hợp với các cảm biến tiên tiến và bộ điều khiển PID để có hiệu suất tối ưu.

- HST-01 có thể tùy chỉnh được không?

- Có, HST-01 cung cấp hàm kẹp có thể tùy chỉnh và phần mềm tùy chọn để nâng cao chức năng.