The syringe compression force test is a critical procedure for assessing the performance and safety of medical syringes. It measures the force required to move the plunger within the syringe barrel, simulating the conditions that occur during the actual use of syringes. This test is essential in ensuring the syringe’s reliability and functionality, especially for medical applications where precision and quality control are paramount.

What is the Syringe Compression Force Test?

The syringe compression force test evaluates the amount of force required to move the plunger inside a syringe barrel. This force must be consistent and fall within a specified range to ensure smooth operation of the syringe when in use. Inconsistent or excessive force could lead to difficulty in delivering the required medication, thus impacting patient safety.

This test is typically performed under controlled conditions, simulating the use of the syringe for fluid withdrawal or injection. The force measurement helps manufacturers assess factors like friction between the syringe barrel and plunger, the quality of lubrication (if any), and the materials used in syringe construction.

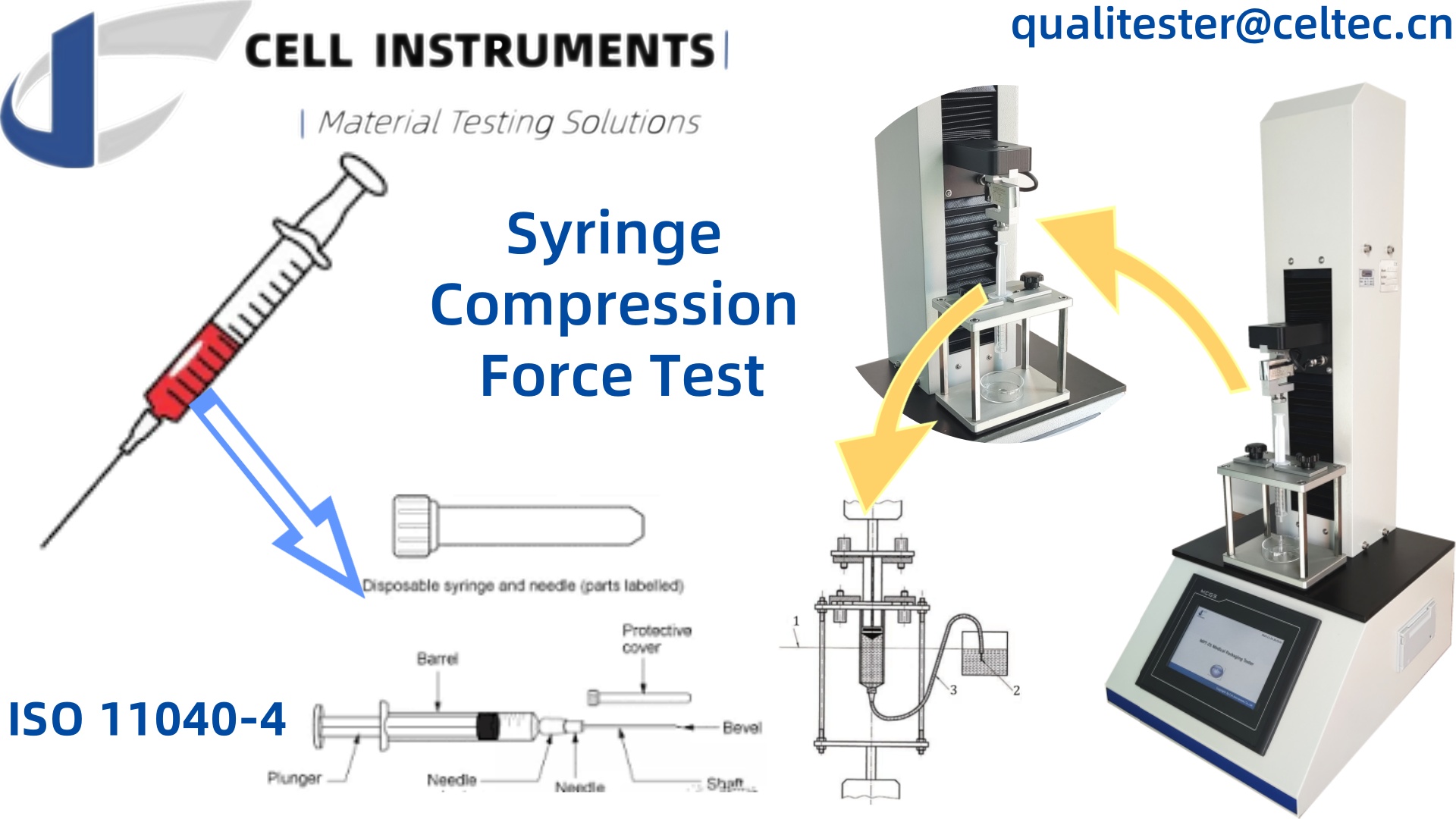

ISO 11040-4 and Its Role in Syringe Compression Force Testing

ISO 11040-4 is a key standard in the syringe manufacturing industry, particularly concerning the performance of syringes. It outlines the test methods for the plunger glide force, which is directly related to the syringe compression force. According to ISO 11040-4, the glide force test is used to evaluate the consistency of the syringe’s plunger movement and assess the impact of lubrication (such as silicone oil) or non-lubricated syringes in their intended usage.

Importance of Following ISO 11040-4

Compliance with ISO 11040-4 ensures that the syringes meet international quality and safety standards. By adhering to these standards, manufacturers can guarantee that their products are not only functional but also reliable and safe for end-users, reducing the risk of malfunction during use.

Syringe Compression Force Test Procedure

The syringe compression force test is conducted using a specialized testing device, such as the MST-01 Medical Syringe Tester from Cell Instruments. This tester can measure various forces, including the force required to operate the piston, syringe sliding resistance, and needle penetration force.

Step-by-Step Process

- Prepare the Syringe: An empty syringe, either with or without a needle, is prepared for testing. If applicable, the plunger stopper is positioned at a specific location inside the syringe barrel.

- Set the Testing Speed: The syringe is placed into a testing machine, such as the MST-01, which uses a precision ball screw mechanism for accurate speed and displacement control. The test speed can vary, but it is typically set at 100 mm/min to mimic normal operational conditions.

- Apply Compression Force: The tester applies force to the syringe plunger, moving it along the barrel. The force required to initiate movement and overcome resistance is recorded.

- Measure Maximum Force: The maximum force required to move the plunger is recorded. This is the compression force, and it must fall within the prescribed limits for the syringe to be deemed functional.

- Repeat for Additional Samples: The process is repeated for additional syringes to ensure consistency and reliability across different units.

- Data Recording: The data from each test, including the maximum compression force, is documented. This data helps manufacturers assess the performance of their syringes and ensure they meet the required standards.

Why Syringe Compression Force Testing is Critical

The syringe compression force test plays a crucial role in ensuring the quality and safety of syringes. Poor compression force can lead to issues such as difficulty in administering medication, excessive friction, or even syringe failure. Testing ensures that syringes will perform optimally, especially in critical medical situations.

Cell Instruments MST-01: A Solution for Syringe Compression Force Testing

For accurate and reliable syringe compression force testing, Cell Instruments’ MST-01 Medical Syringe Tester is a great choice. The MST-01 is equipped with advanced features like a precision ball screw for speed and displacement control, a touch screen for easy operation, and the ability to perform multiple force-related tests. This makes it an ideal tool for syringe manufacturers to ensure their products meet international standards like ISO 11040-4.

FAQ

1. What is the purpose of the syringe compression force test?

The test measures the force needed to move the plunger within the syringe barrel to ensure smooth and consistent operation, which is crucial for syringe functionality and patient safety.

2. How is the syringe compression force test conducted?

The syringe is placed into a testing machine, and force is applied to the plunger to measure the resistance as it moves through the barrel. The maximum force required is recorded and analyzed.

3. What are the standards for syringe compression force testing?

ISO 11040-4 is the primary standard that outlines the test methods for evaluating the glide force of the syringe plunger, which is closely related to the syringe compression force.

4. Why is it important to test syringe compression force?

Testing ensures that the syringe operates smoothly and reliably, preventing issues such as excessive friction or plunger jamming that could lead to complications during medication administration.

5. How can the MST-01 Medical Syringe Tester help in compression force testing?

The MST-01 provides precise measurements, a user-friendly interface, and a variety of test programs to evaluate syringe performance, ensuring compliance with international standards like ISO 11040-4.

Related Product

Syringe Plunger Glide Force Tester

Related Article

Syringe Breakaway Force Testing

Syringe Plunger Glide Force Test

Syringe Piston Glide Force Test