The testing principle and technical characteristics of the packaging airtightness tester

The packaging leak tester is also called the packaging leak detector. It is an instrument specially used by production and processing enterprises to test the airtightness of packaging bags, bottles, jars and other containers in the food, dairy and pharmaceutical industries, so as to ensure that the product will not leak due to packaging. And produce quality problems (some leakage points are invisible to the naked eye), prolong the shelf life of the product.

The test method is based on “GB/T15171-94 Test Method for Sealing Performance of Flexible Packages”

Flexible packaging

For flexible packaging with airtight performance, the packaging materials used must not have any defects that affect the airtight performance, such as pinholes, cracks, unsealed and unsealed seals.

Sealing Performance

The ability of flexible packaging to prevent the entry of other substances or the escape of the contents.

Test Principle

Method One

This method is used for packages where the performance of the outer material under the action of water will not be significantly reduced during the test, such as packages with plastic film as the outer layer.

By evacuating the vacuum chamber, the sample immersed in water produces a pressure difference between the inside and outside, and observes the gas escape or water infiltration in the sample, so as to determine the sealing performance of the sample.

Method Two

This method is used for packages where the performance of the outer material will be significantly reduced during the test period under the action of water, such as a package with an outer layer of paper material.

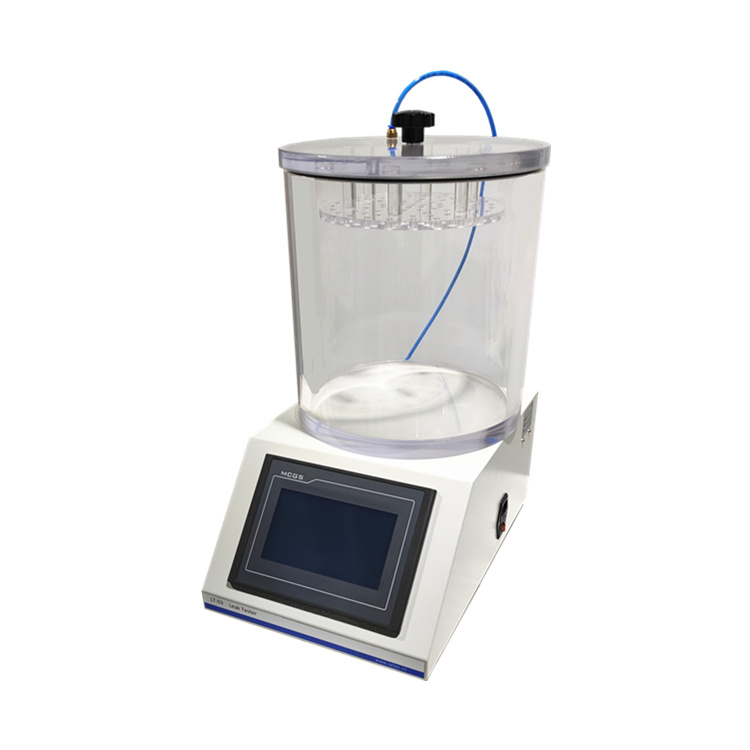

Test device

The test apparatus shall be divided into the following parts.

Vacuum chamber: It consists of a vacuum container made of transparent material that can withstand a pressure of 100kPa and a sealed cover.

The vacuum container is used to hold the test liquid and the test sample; the sealing cover is used to seal the vacuum chamber. When vacuuming, the sealing cover should be able to ensure the airtightness of the vacuum chamber.

During the test, the maximum vacuum degree that can be achieved in the vacuum chamber should not be lower than 95 kPa, and the vacuum degree can be reached from normal atmospheric pressure within 30-60 s.

Sample fixture: used to fix the sample in the test liquid in the vacuum chamber, and its material and shape must not affect the performance of the sample and the test observation.

Pipeline: including the vacuum tube connected to the vacuum source and the exhaust tube connected to the atmosphere. Both shall be fitted with valves.

Vacuum gauge: It is used to measure the vacuum degree in the vacuum chamber, and its accuracy shall not be lower than 1.5 grade.

Control device: including vacuum switch, vacuum adjustment device, intake valve, etc.

Product Features

The test process is fully automatic

Man-machine interface, touch screen operation

Digital vacuum degree and test time setting

Automatic vacuum maintenance and back blowing unloading

Five sets of test parameter setting storage

Automatic statistics and storage of test results

Ultra-thick vacuum chamber plexiglass

Vacuum chamber non-standard size can be customized

Compressed air is the power source, no vacuum pump required

Technical Parameters

Vacuum degree: 0~-90KPa

Vacuum chamber: Φ270 mmx210 mm (H) (other sizes can be customized)

Size: 300mm(L)X380mm(W)X500mm(H)

Air source: air compressor

Air source pressure: 0.7MPa (user-provided air source)