Introduction to the Melt Flow Index Tester

The เครื่องทดสอบดัชนีการไหลละลาย is a high-precision instrument designed to measure the melt flow characteristics of thermoplastic materials under controlled conditions. By determining the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR), this tester provides valuable insights into the processability of polymers, which is essential for quality control, material selection, and manufacturing optimization. Whether used in the automotive, pharmaceutical, food packaging, or electronics industries, the Melt Flow Index Tester ensures that materials meet specific flow properties for reliable processing.

Applications of the Melt Flow Index Tester

The Melt Flow Index Tester is widely used in industries that require precise polymer material testing. It is particularly suitable for testing engineering plastics with high melting points, such as polyarylsulfone, nylon, fluoroplastics, และ polyethylene, as well as plastics with lower melting points, including polypropylene, ABS, polystyrene, และ polyoxymethylene. By accurately measuring the flow rate of these materials, manufacturers can ensure that their plastics will behave predictably during processing and meet product specifications.

Industries:

- Packaging: Ensures consistent material flow for packaging films and containers.

- Automotive: Verifies the reliability of plastics used in vehicle components.

- Pharmaceuticals: Confirms consistency in the manufacturing of drug delivery systems.

- Electronics: Tests the flow characteristics of materials used in electronic components.

- Medical: Assesses the processability of medical device materials.

Test Principle

The Melt Flow Index Tester determines the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) by extruding molten material from a heated cylinder through a die of specified length and diameter under preset conditions of temperature and load.

- MFR (Procedure A): This method calculates the extrusion rate by measuring the weight of extruded material over a set period (typically 10 minutes) in grams per 10 minutes (g/10 min).

- MVR (Procedure B): In this method, the piston displacement is measured over a given time or distance, providing the extrusion rate in cubic centimeters per 10 minutes (cm³/10 min).

MVR can be converted to MFR, or vice versa, if the melt density of the material at the test temperature is known.

ISO 1133 and ASTM D1238 Standards

The Melt Flow Index Tester complies with the internationally recognized standards ISO 1133 and แอสทาม D1238, ensuring accurate and reproducible results in measuring the flow properties of thermoplastics.

- ใบรับรอง ISO 1133-1 and ตามมาตรฐาน ISO 1133-2 specify test methods for MFR and MVR determination.

- แอสทาม D1238 provides guidelines for measuring the melt flow rate of thermoplastic materials under controlled temperature, load, and die conditions.

These standards are crucial for ensuring consistency across different laboratories, manufacturers, and industries.

Test Methods for MFR and MVR

- Mass-Measurement Method (MFR): This test weighs the extrudate produced over a timed interval and uses this data to calculate the melt flow rate in grams per 10 minutes.

- Displacement-Measurement Method (MVR): Measures the piston’s movement and calculates the extrusion rate in cubic centimeters per 10 minutes.

Load and Temperature Control are critical in ensuring consistent results. The Melt Flow Index Tester can accommodate multiple load options ranging from 0.325 kg to 21.6 kg depending on the material being tested, and the temperature is precisely controlled to match the testing standards.

Melt Flow Index (MFR) and Melt Volume-Flow Rate (MVR)

- MFR (Melt Mass-Flow Rate): MFR is the rate at which a polymer material is extruded through a die under specified conditions of load, temperature, and die dimensions. MFR is reported in grams per 10 minutes (g/10 min) or decigrams per minute (dg/min).

- MVR (Melt Volume-Flow Rate): MVR measures the volume of extruded material per unit of time (cubic centimeters per 10 minutes) and is particularly useful when dealing with materials that do not have a constant melt density.

These measurements are vital for manufacturers to determine how easily a plastic can be processed, affecting its use in various applications, from injection molding to extrusion.

Load in MFR and MVR Testing

The load in MFR and MVR testing refers to the combined force exerted by the piston and any added weights. This force is crucial for determining the extrusion rate of the material under specific conditions. The nominal loads typically used for testing are 0.325 kg, 1.200 kg, 2.160 kg, 3.800 kg, 5.000 kg, 10.000 kg, และ 21.600 kg. The correct load is selected based on the material’s viscosity and the desired test conditions.

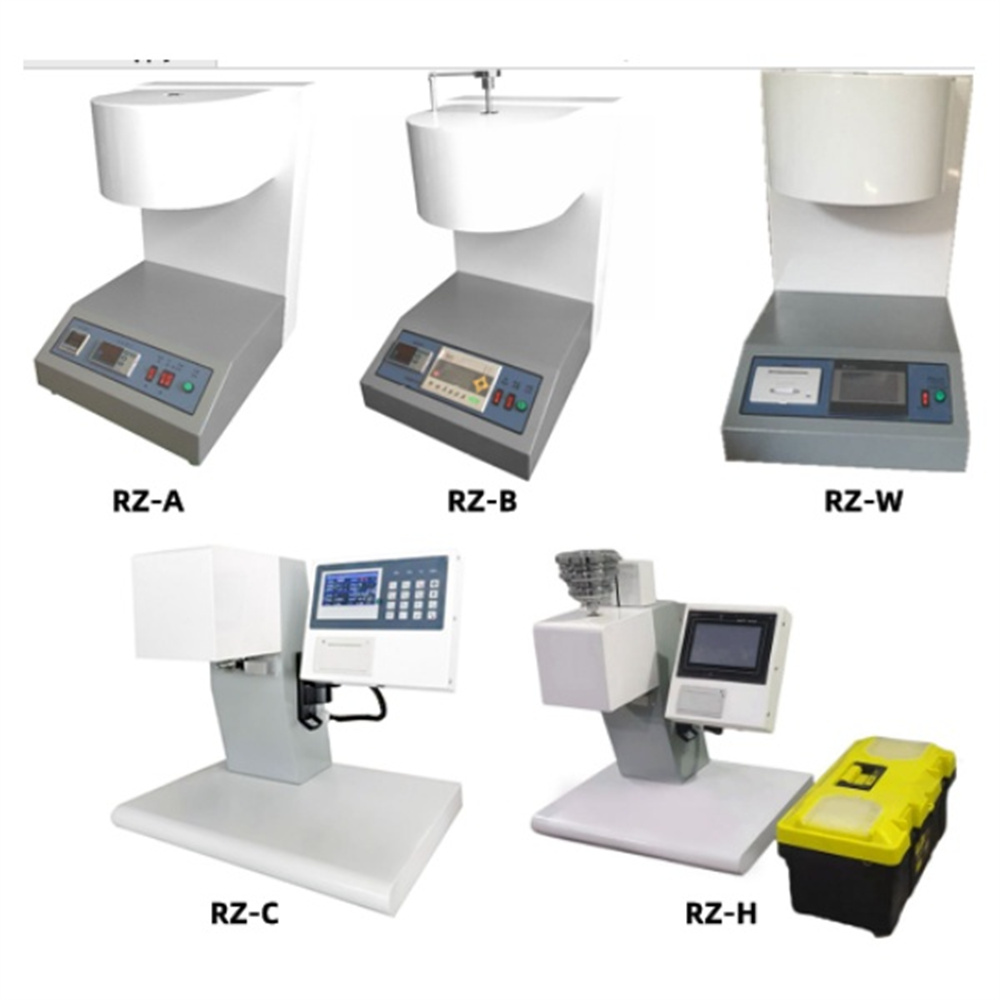

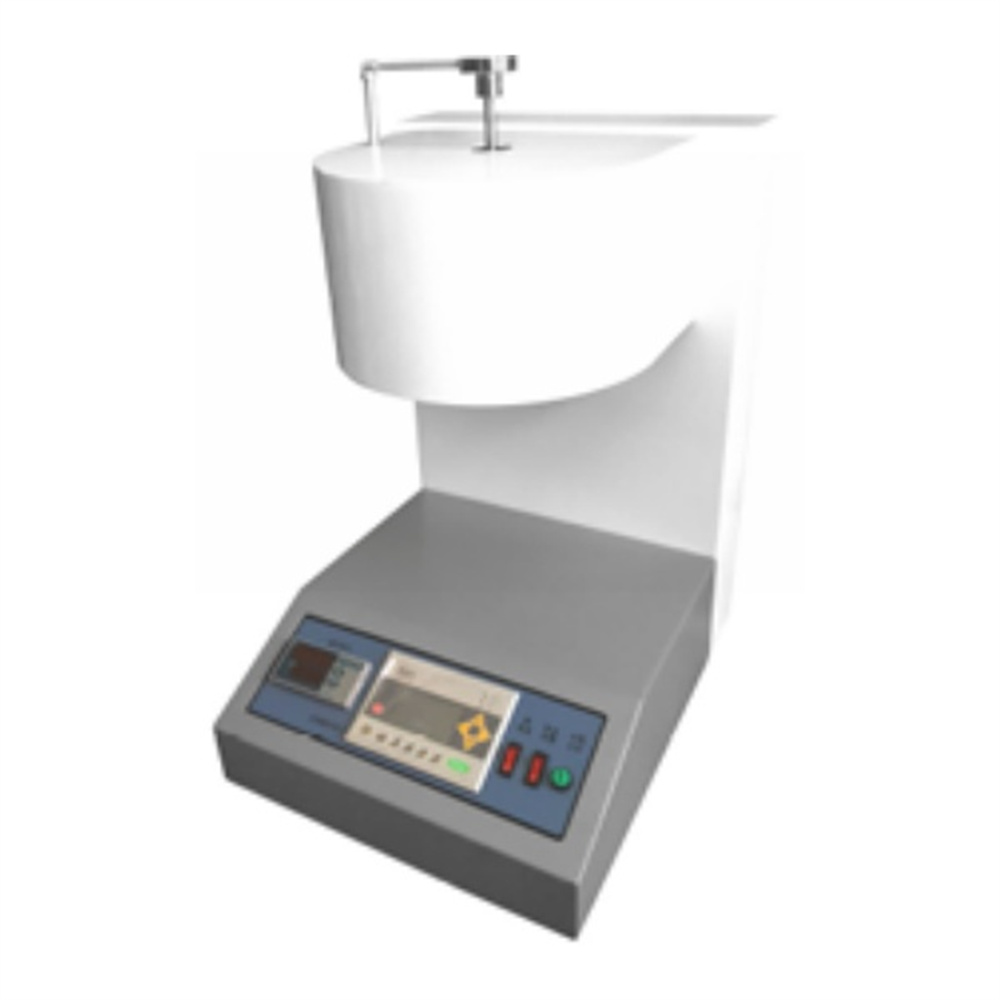

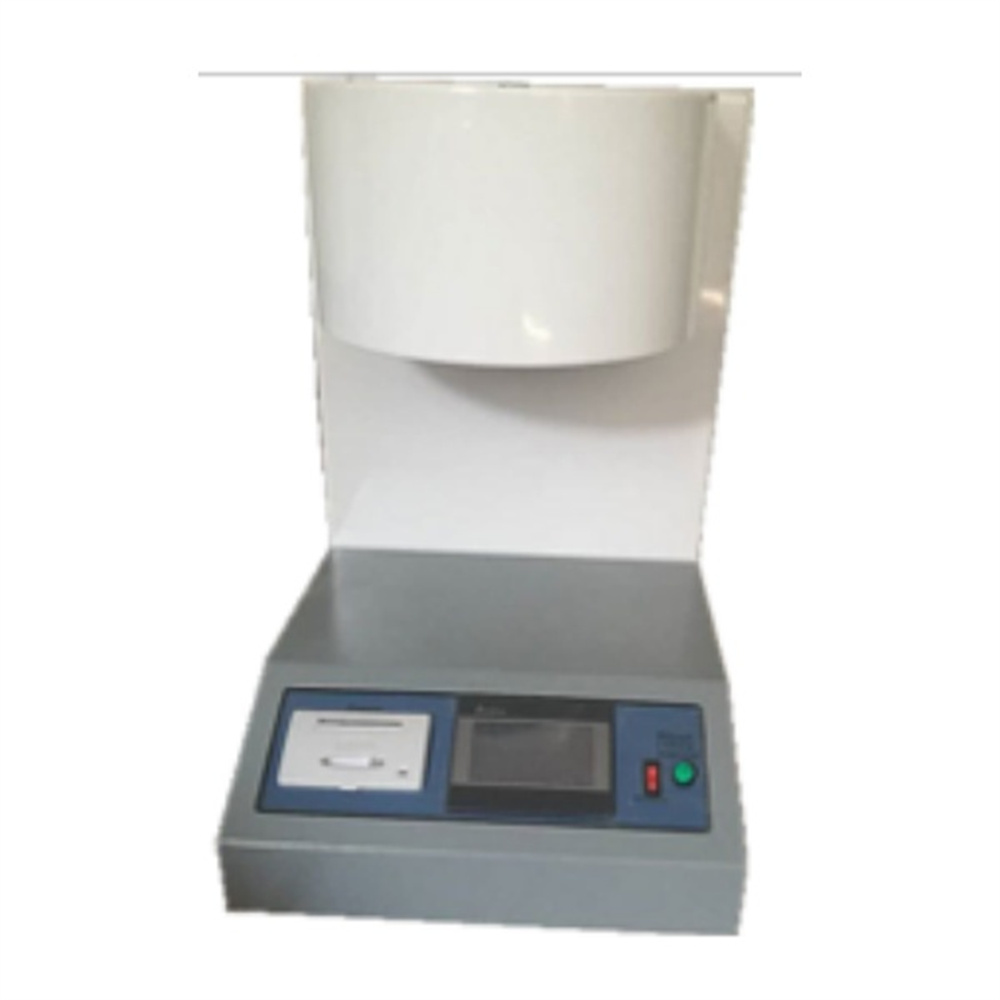

Key Features of the Melt Flow Index Tester

- Precision Temperature Control: Adjustable heating elements ensure accurate and consistent temperature control for reliable testing of a wide range of thermoplastics.

- Flexible Load Options: Choose from a range of nominal weights to suit different materials and test conditions.

- User-Friendly Interface: Simple controls make the Melt Flow Index Tester easy to operate, allowing quick setup and accurate testing.

- Data Logging and Reporting: Provides accurate MFR and MVR values, which can be logged and stored for later analysis or quality assurance purposes.

Why Choose Cell Instruments’ Melt Flow Index Tester?

Cell Instruments’ Melt Flow Index Tester is engineered to provide the highest level of accuracy and consistency in measuring MFR and MVR according to ISO 1133 and ASTM D1238 standards. Our testers are designed with durability and ease of use in mind, featuring robust construction and intuitive controls.

Benefits:

- Accurate Results: Meets international standards to ensure precise flow measurements.

- Customizable Options: Configurable for a wide range of polymers and testing requirements.

- Reliability: Designed for continuous use in industrial and research settings.

- Compliance with Industry Standards: Conforms to ISO 1133 and แอสทาม D1238, ensuring reliable and repeatable testing.

The Melt Flow Index Tester is an essential tool for assessing the flow behavior of thermoplastics, ensuring that materials meet their processing requirements. Whether for quality control, material research, or manufacturing optimization, this tester provides reliable and accurate results, complying with ISO 1133 and แอสทาม D1238 standards. With customizable options and user-friendly operation, Cell Instruments’ Melt Flow Index Tester is the ideal choice for any laboratory or production environment.