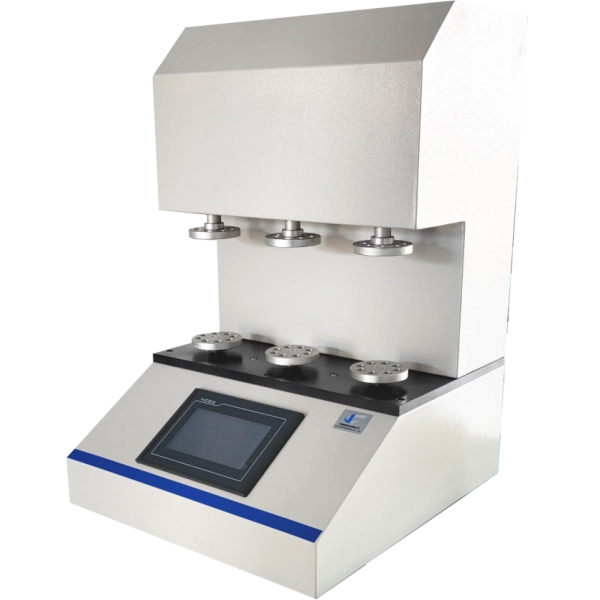

เครื่องทดสอบการหดตัวแบบ GFT

In the packaging industry, ensuring the durability of materials is essential to prevent damage during transportation and handling. The crumple flex tester is a vital instrument used to assess the flex durability of materials, including films, composites, and coatings. By simulating repetitive stresses that packaging materials face during distribution, this tester helps manufacturers ensure the structural integrity of their products.

การ crumple flex tester is designed to simulate the mechanical stresses that packaging materials endure when subjected to flexing, twisting, and compression. These actions often lead to flex cracks and perforations, which can compromise the packaging’s integrity and the product’s safety. The tester helps manufacturers gauge the material’s resistance to these stresses and evaluate its performance under repeated strain.

The primary purpose of the crumple flex tester is to assess the flex durability of flexible barrier materials, such as plastic films, coated papers, and laminates, which are commonly used in packaging. The tester operates by subjecting samples to a combination of twisting and linear compression motions that simulate the physical forces a package might face during handling, transport, and distribution.

ASTM F392 and the Gelbo Flex Test Method

การ แอสทาม F392 standard, titled “Standard Test Method for Flex Durability of Flexible Barrier Materials,” is the benchmark for evaluating the flex durability of materials used in flexible packaging. The crumple flex tester complies with this standard and uses the Gelbo Flex Test Method to quantify how well materials resist damage when subjected to repeated flexing.

การ Gelbo Flex Test Method evaluates the material’s ability to withstand flexing over time, which is crucial in preventing packaging failure. The method involves repeatedly flexing a sample, usually a film or coating, through a twisting and compression motion. Over time, this flexing can cause microscopic cracks or perforations, which the tester identifies, providing critical data on the material’s durability.

How the Crumple Flex Tester Works

The crumple flex tester works by mounting a sample, typically measuring 200 mm by 280 mm, on mandrels. These mandrels then initiate the flexing process, which involves a twisting motion of 440 degrees over 90 mm of the stroke followed by horizontal compression. This process is repeated at a speed of 45 cycles per minute, allowing the tester to simulate real-world conditions accurately.

The tester offers different testing modes based on the แอสทาม F392 standard:

- Mode A: Full flex for 1 hour (2,700 cycles)

- Mode B: Full flex for 20 minutes (900 cycles)

- Mode C: Full flex for 6 minutes (270 cycles)

- Mode D: Full flex for 20 cycles

- Mode E: Partial flex for 20 cycles

These modes provide flexibility, allowing users to customize testing conditions according to their specific needs.

Applications of the Crumple Flex Tester

การ crumple flex tester is essential for manufacturers in industries that rely heavily on packaging materials, such as:

- บรรจุภัณฑ์: To ensure the strength and integrity of flexible barrier films used in food, beverage, and medical packaging.

- Plastics and Textiles: To test the durability of plastic films, laminates, and textile coatings that are used in flexible packaging.

- Pharmaceuticals and Cosmetics: To assess the performance of packaging materials that need to withstand repeated flexing without compromising the safety of the contents.

For example, manufacturers can use the tester to evaluate the performance of films used in medical packaging, ensuring that they do not tear or puncture during distribution, which could lead to contamination or spoilage.

พารามิเตอร์หลัก

Crumple Flex Tester – Main Parameter

คุณสมบัติทางเทคนิค

Crumple Flex Tester – Technical Feature

การ crumple flex tester is an essential tool for testing the flex durability of materials used in flexible packaging. By adhering to the แอสทาม F392 standard and using the Gelbo Flex Test Method, manufacturers can ensure that their packaging materials will perform reliably under real-world conditions. This not only helps protect the products but also ensures compliance with industry standards, contributing to higher customer satisfaction and safety.

For companies in the packaging industry, investing in a crumple flex tester from Cell Instruments ensures that your materials undergo rigorous testing, improving product reliability and performance.