Test procedure of friction coefficient meter

The coefficient of friction meter is used to measure the coefficient of static friction and coefficient of dynamic friction when materials such as plastic films and sheets, paper, etc. slide. By measuring the slipperiness of the material, it is possible to control and adjust the production quality process indicators of the material to meet the product use requirements. The coefficient of friction meter can also be used to measure the static friction coefficient of rubber, cardboard, woven bags, fabric styles, metal material composite belts for communication cables, conveyor belts, wood, coatings, brake pads, wipers, shoe materials, tires and other materials when sliding and coefficient of kinetic friction.

The following is based on “GB/T 10006-2021 Determination of Coefficient of Friction of Plastic Films and Sheets”.

Test principle

The principle of the test is to put the two test surfaces together, under a certain contact pressure, make the two surfaces move relative to each other, and record the required force. The friction coefficient value is obtained by dividing the tested force value by the gravity of the slider. Terms and Definitions Friction The action of hindering the sliding of two contacting surfaces. Divided into kinetic friction and static friction. static friction static friction The moment the sliding begins, the “critical” friction that needs to be overcome. dynamic friction The friction that exists during sliding at a given velocity. frictional force The force required to overcome friction. It is divided into static friction force FS and dynamic friction force FD normal force normal force is the force applied perpendicularly to the two contact surfaces. FP friction coefficient coefficient of friction friction and normal force ratio. Static coefficient of friction static coefficient of frictionμs=static friction FS/normal force FP dynamic coefficient of friction μD=dynamic friction FD/normal force FP Note 1: The friction coefficient of the film is usually between 0.2-1 Ideally, the coefficient is an inherent property independent of the test instrument and test conditions. Since the film is usually not ideal, GB/T 10006-2021 specifies all test parameters.

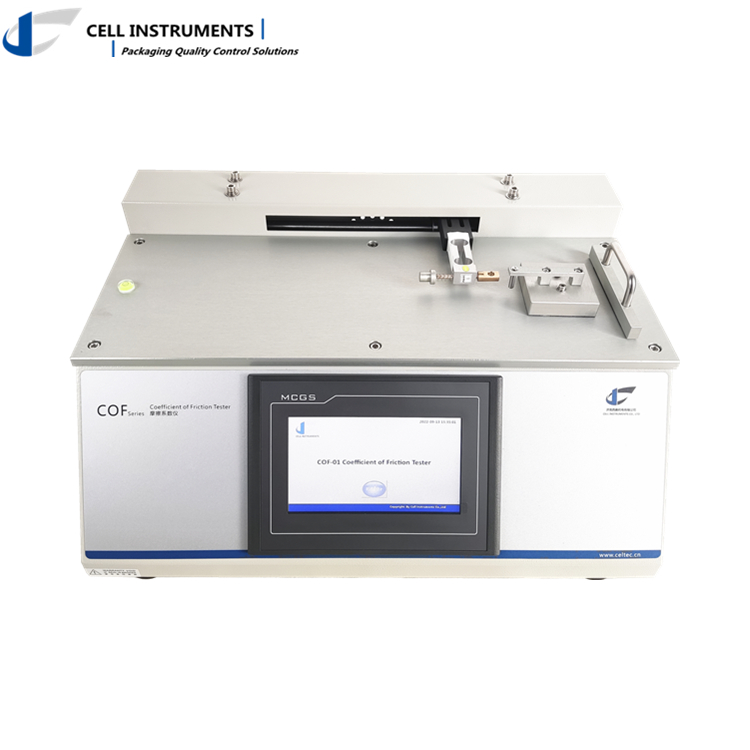

Test equipment

The test device consists of a horizontal test bench, a slider, a force measuring system and a drive mechanism that moves the two test surfaces on the horizontal test bench relative to each other. Either sliders or platforms can be used as moving parts.

Equipment requirements

The surface of the horizontal test bench should be smooth and made of non-magnetic metal material.

The normal force is generated by the slider. The slider should have a square bottom surface with an area of 40cm² (side length 63mm). In order to make the pressure evenly distributed, the bottom of the slider should be covered with elastic materials such as felt. The elastic material must not cause “embossing” of the sample . The total mass of the slider should be 200g ± 2g to produce a normal force of 1.96N ± 0.2N.

The driving structure should have no vibration, so that the two test surfaces move relatively at a speed of 100mm/min±10mm/min. When there are special needs, the speed can be set to 500mm/min±10mm/min.

The total error of the entire force measuring system including the recorder should not exceed 2%, the conversion time should not exceed 0.5s, and the traction direction should be kept parallel to the friction plane and on a straight line.

For the measurement of static friction, the elastic coefficient of the force measuring system should be adjusted to 2N/cm ± 1N/cm by an appropriate spring. When measuring kinetic friction in the slip-stick situation, the spring is replaced by a rigid connection.