Syringe Glide Force Test: Ensuring Precision and Safety in Medical Syringe Functionality

In the medical and pharmaceutical industries, syringe functionality plays a crucial role in ensuring safe and effective drug delivery. One of the most vital tests in evaluating syringe performance is the syringe glide force test. This test measures the force required to move the syringe piston, a critical factor in the device’s usability and reliability. Understanding the procedures, standards, and significance of this test is essential for manufacturers to comply with regulatory requirements and maintain product quality.

What Is the Syringe Glide Force Test?

The syringe glide force test, also known as the “force to initiate piston movement” test, measures the force required to move the piston within the syringe barrel. This test is crucial for ensuring that the syringe provides smooth and consistent operation, essential for both user comfort and medication accuracy. The test helps identify issues like excessive friction between the syringe piston and barrel, which could cause discomfort or hinder the drug delivery process.

Why Is the Syringe Glide Force Test Important?

The glide force test ensures that syringes have an optimal balance of resistance, preventing both too little and too much force needed to operate the piston. Insufficient resistance may result in unintended movement, while excessive resistance can lead to difficulties in administration, possibly causing user frustration or even medication errors. By conducting this test, manufacturers can ensure that syringes are safe, easy to use, and meet industry standards.

ISO 8537 and the Glide Force Test

The ISO 8537 standard provides guidelines for evaluating the force required to operate the syringe piston. It outlines the test method and specifies the equipment and procedures needed to ensure accurate and reliable test results. This standard is essential for manufacturers to follow to meet regulatory requirements, ensuring that their syringes perform within acceptable limits for safety and efficacy.

Understanding the Test Procedure

According to the ISO 8537 guidelines, the syringe glide force test is typically conducted using a mechanical testing machine. This machine expels water from the syringe while simultaneously recording the force required to move the piston. The key steps in the process include:

- Preparation: The syringe is filled with water to 50% of its nominal capacity.

- Force Application: The syringe is securely clamped in place, and a downward force is applied to the piston using a force gauge.

- Measurement: The force required to initiate piston movement is recorded, along with the maximum force needed to fully depress the plunger.

These steps ensure a consistent and accurate measurement of the glide force, providing valuable data for quality control and compliance.

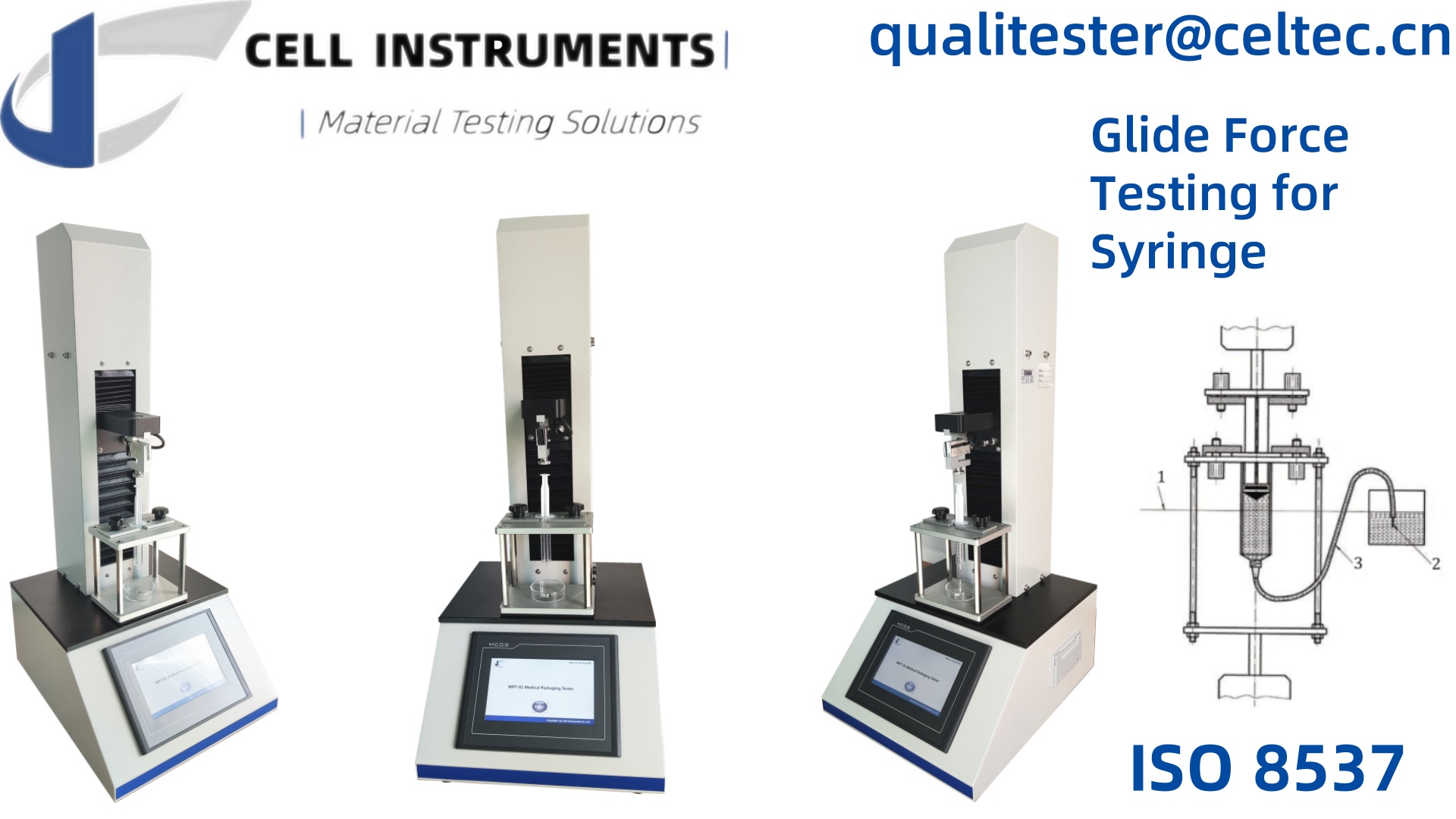

The Role of the MST-01 Medical Syringe Tester

For manufacturers seeking precision and ease of use in their testing, the MST-01 Medical Syringe Tester is an ideal solution. This advanced testing machine offers a range of features that make it highly suitable for conducting syringe glide force tests in line with ISO 8537 and other relevant standards.

The MST-01 includes:

- Multiple test programs for a variety of syringe tests, including glide force testing.

- Precise displacement control using a ball screw mechanism for accurate measurement.

- Variable test speeds, allowing users to tailor testing parameters based on specific syringe types.

- User-friendly interface with a 7-inch touch screen for easy operation.

- Real-time data recording and output through a microprinter or optional RS232 interface for detailed reporting.

By using the MST-01 Medical Syringe Tester, manufacturers can ensure consistent, reliable results, improving product quality and meeting international testing standards.

Key Benefits of the Syringe Glide Force Test

- Safety Assurance: The glide force test ensures that syringes are easy to use, reducing the risk of improper medication delivery due to mechanical failure.

- Regulatory Compliance: Following standards like ISO 8537 helps manufacturers meet regulatory requirements for syringe functionality.

- User Experience: A properly calibrated syringe glide force guarantees a smoother experience for healthcare professionals and patients alike.

- Quality Control: Consistent testing helps identify potential design flaws in syringes, leading to improved product development and manufacturing processes.

The syringe glide force test is a fundamental procedure for evaluating syringe performance, ensuring that syringes provide consistent, smooth, and safe operation. Compliance with ISO 8537 standards is essential for manufacturers aiming to meet industry regulations and deliver high-quality products to the market. With advanced testing equipment like the MST-01 Medical Syringe Tester, companies can streamline their testing processes, ensuring reliability and safety in their syringe products.

Frequently Asked Questions (FAQ)

1. What is the purpose of the syringe glide force test?

The syringe glide force test measures the force required to move the syringe piston, ensuring smooth and consistent operation. This is critical for user comfort and accurate drug delivery.

2. How is the glide force test conducted?

The test involves filling the syringe with water, clamping it to a testing machine, and applying a downward force to the piston while recording the force required to move it.

3. What is ISO 8537, and why is it important?

ISO 8537 is the international standard that provides guidelines for testing the force required to operate a syringe piston. It ensures that syringes meet regulatory requirements for safety and functionality.

4. How does the MST-01 Medical Syringe Tester help in the glide force test?

The MST-01 provides precise displacement control, variable speeds, and multiple test programs, making it an ideal tool for conducting accurate syringe glide force tests in line with ISO 8537.

5. What happens if a syringe fails the glide force test?

If a syringe fails the glide force test, it indicates that the piston may be too difficult or too easy to move, which could lead to issues during injection. Further design adjustments or quality improvements are required to meet industry standards.

Related Product

Syringe Plunger Glide Force Tester

Related Article

Syringe Breakaway Force Testing

Syringe Plunger Glide Force Test

Syringe Piston Glide Force Test