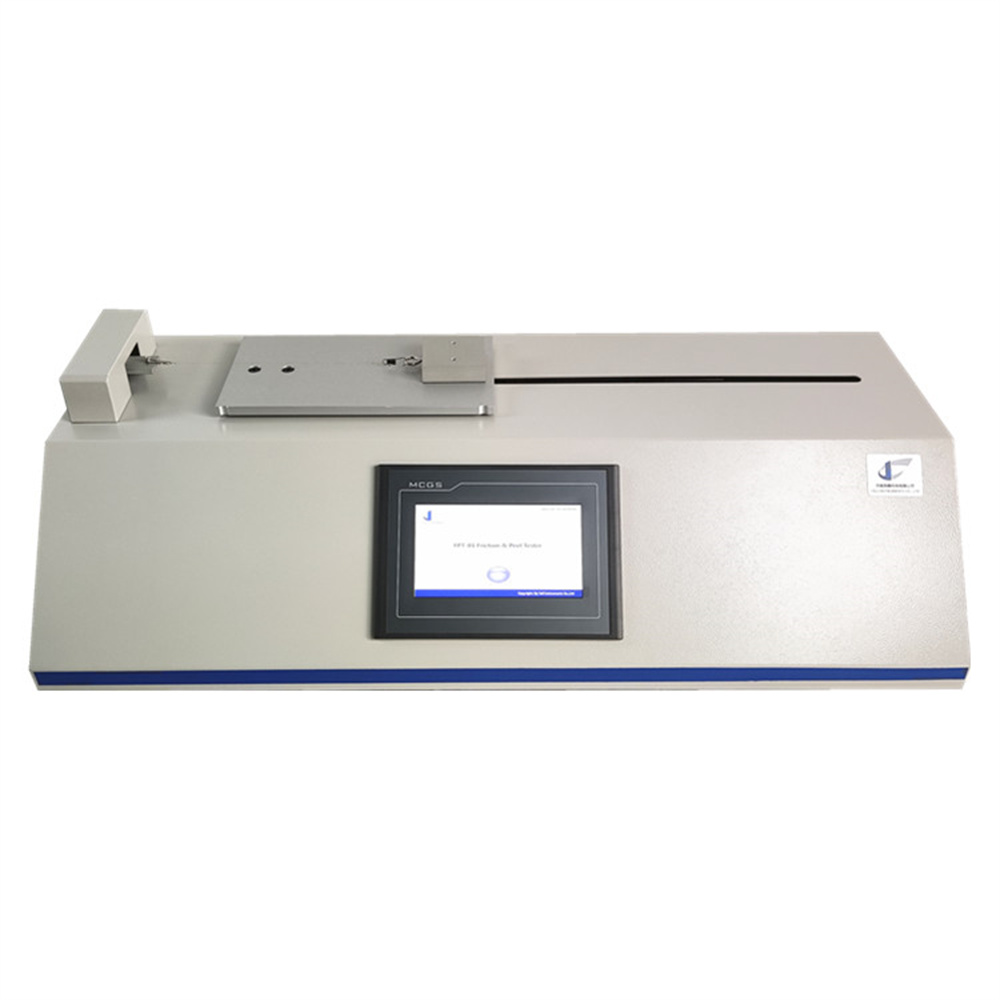

Introduction of Film Friction/Peel Tester

The Film Friction/Peel Tester is an advanced instrument designed for precise measurement of friction and peel resistance across a wide range of materials. With applications spanning industries such as packaging, medical devices, pharmaceuticals, and textiles, this versatile device plays a crucial role in quality control, product development, and research.

Core Features of the Film Friction/Peel Tester

COF Testing

This tester accurately measures both static and kinetic coefficients of friction, essential for understanding material interactions.

Peel Testing

It also conducts delicate peeling force tests on various materials, including release papers, adhesive tapes, and protective films.

Технические характеристики

- System Design: The tester includes a fixed load cell position with a protective cover, ensuring safe operation. The sled mechanism facilitates accurate testing, where samples are securely clamped, and peeling forces are recorded during separation.

- User-Friendly Interface: Featuring a PLC-controlled system, the Film Friction/Peel Tester operates through an intuitive HMI touch screen, making it easy for users to navigate and operate.

Основной параметр

| Force Range | 5 N ( or as required) |

| Точность | ±0.5% |

| Разрешение | 0.001N |

| Displacement Range | 0.1 ~ 95 mm |

| Точность | ±0.1 mm |

| Диапазон температур | Ambient ~ 210°C |

| Точность | ±0.5°C |

| No. of Specimens | 2 |

| Размер выборки | 110*15 mm, L*W |

| Источник питания | 220В 50Гц |

Соответствие отраслевым стандартам

- ASTM D1894: Coefficient of Friction for Plastics

- ASTM D3330: Peel Adhesion for Pressure Sensitive Tape (180°)

- ИСО 8295: Coefficient of Friction for Plastics, ensuring material quality in manufacturing.

- ТАППИ Т816: Coefficient of Friction for Corrugated and Paperboard.

- ТАППИ Т549: Coefficient of Friction for Uncoated Writing & Printing Paper.

Applications of the Film Friction/Peel Tester

The Film Friction/Peel Tester is utilized in diverse sectors, including:

- Упаковка: Ensuring that packaging materials meet performance standards.

- Adhesive: Testing adhesives and barrier materials for reliability.

- Пищевая промышленность: Evaluating seal strength and material interaction for safety and quality.

- Текстиль and Consumer Goods: Assessing material properties to enhance product durability and functionality.

Advantages of the Film Friction/Peel Tester

- Enhanced Product Performance: By accurately measuring friction and peel strength, manufacturers can improve product quality and durability.

- Real-Time Data Analysis: The system provides immediate results, including graphical representations of data for easy interpretation.

- Advanced Features: Additional functionalities include integrated printing and optional software for comprehensive data management.

The Film Friction/Peel Tester is an essential tool for any organization focused on material quality and compliance with industry standards. By delivering precise measurements and adhering to recognized testing protocols, this tester supports manufacturers in achieving optimal product performance. Explore the capabilities of the Film Friction/Peel Tester today to ensure your materials meet the highest standards of quality.