ASTM F1140

Материалы для подачи заявления

ASTM F1140 is applied to flexible packaging materials used in various industries, including food, medical, pharmaceutical, and consumer goods. These materials are tested to determine their burst strength and integrity.

Процесс тестирования

- Подготовка: Select the appropriate packaging material sample.

- Кондиционирование: Condition the sample to the required temperature and humidity levels.

- Настраивать: Place the sample in the burst tester. Seal the sample edges securely.

- Давление: Gradually apply pressure to the sample until it bursts.

- Recording: Record the pressure at which the sample bursts.

Интерпретация результатов теста

The burst strength is the pressure at which the sample fails. Results are typically expressed in psi (pounds per square inch) or kPa (kilopascals). Higher burst strength indicates better durability and integrity of the packaging material.

Тест Значимости

The burst strength test helps in evaluating the ability of packaging materials to withstand internal pressures during handling, storage, and transportation. It ensures that the packaging will protect the product effectively and maintain its integrity under stress.

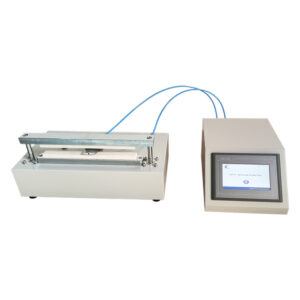

Требования к инструментам

- Burst Tester: An instrument capable of applying uniform pressure to the sample until it bursts.

- Pressure Gauge: Accurate pressure measurement device.

- Sealing Mechanism: To hold the sample securely during the test.

- Conditioning Chamber: To condition samples at specific environmental conditions.

Меры предосторожности

- Ensure samples are representative and free from defects.

- Calibrate instruments regularly to maintain accuracy.

- Condition samples as per standard requirements before testing.

- Follow safety protocols to prevent injuries from burst samples.

Отображение единственного товара