Butyl rubber stoppers have excellent sealing performance and good drug resistance, and are the only sealing rubber stoppers for glass bottles that come into direct contact with drugs in the pharmaceutical industry. current. With the popularization of applications, the application of butyl rubber stoppers is more extensive. The puncture performance of butyl rubber stoppers is an important test index, and specific tests include puncture force and puncture residue.

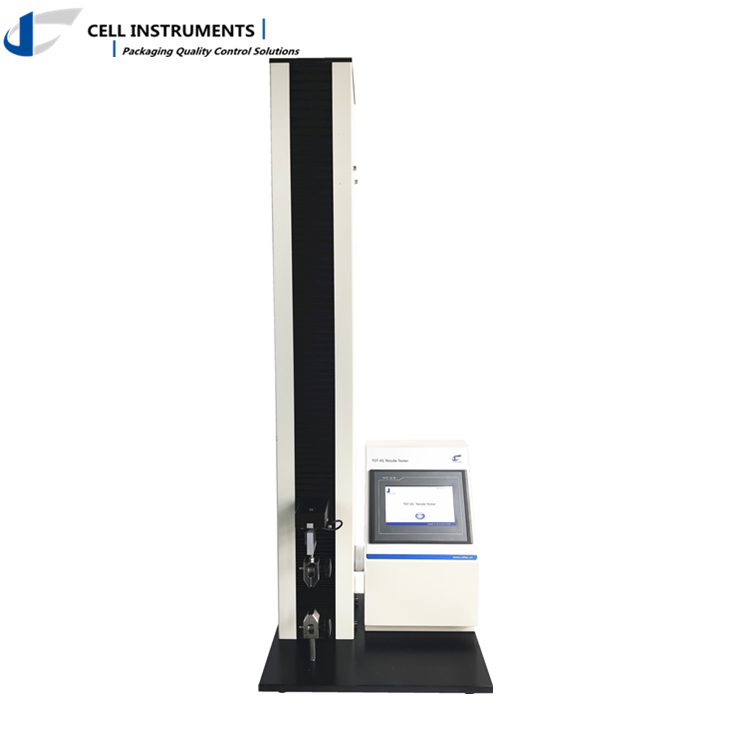

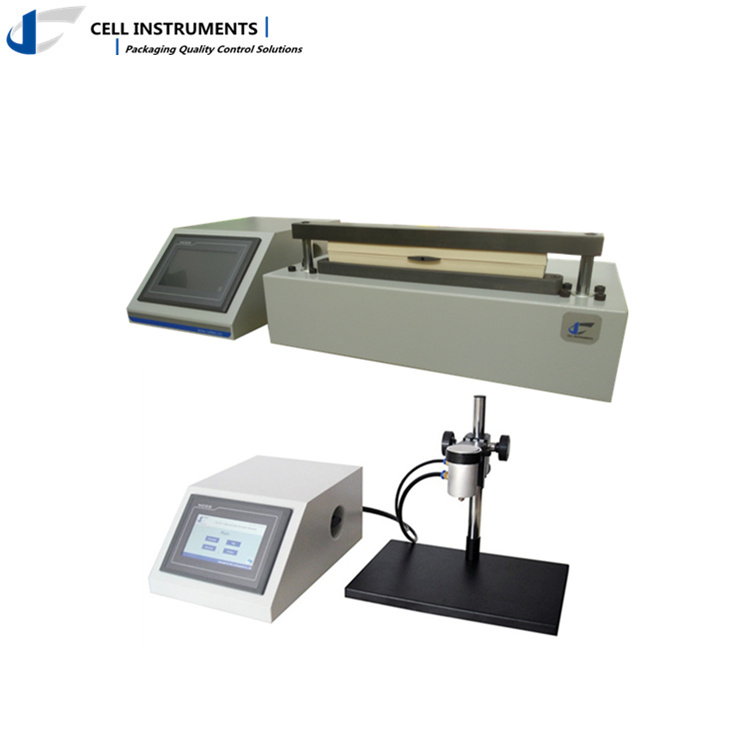

Cell Instruments has continued to provide the best and most comprehensive quality control solutions to the global pharmaceutical field. The TST-01 Tensile Tester, MPT-01 Medical Packaging Tester, BST-01 Ampoule Breaking Tester, etc., can be equipped with jigs for puncture performance testing of butyl rubber stoppers to provide professional services for rubber stopper puncture performance test and pharmaceutical manufacturers.

Such as pharmaceutical aluminum foil, pharmaceutical composite film, pharmaceutical PVC hard film, etc., heat seal strength, tear strength, peel strength test function of pharmaceutical composite membrane materials, greatly improves the utilization rate of equipment in pharmaceutical production enterprises, and also meets the demand of pharmaceutical production enterprises for functions composed of teams.

In addition to the just-introduced butyl rubber stoppers puncture performance tests, Cell Instruments can also provide services for other pharmaceutical packaging materials test items, such as ASTM F2096 micro leak tester, FBT-01 falling ball impact tester, LT-03 vacuum leak tester, LSST-01 Leakage and Seal Strength Tester and other products.