Introduction to Cap Torque Testing

Cap torque testing is essential in ensuring that caps on bottles, containers, and other packaging are properly designed for safe and effective use. Whether it’s pharmaceutical, food, beverage, or consumer goods packaging, the torque required to open and close caps directly impacts both consumer convenience and product safety. The Cap Torque Tester provides manufacturers with the precise measurements necessary to meet regulatory standards and improve the functionality of their packaging.

Major Standards: ASTM D2063, ASTM D3198, ASTM D3474

ASTM D2063: Standard Test Method for Torque Required to Open and Close Child-Resistant Packaging

ASTM D2063 outlines the test method for determining the torque needed to open and close child-resistant packaging, ensuring safety in the packaging of pharmaceuticals and chemicals. This standard is especially relevant for packaging that needs to prevent unintended access by children. The Cap Torque Tester measures both the opening and closing torques required, making it essential for manufacturers to meet child-resistant packaging regulations.

ASTM D3198: Standard Test Method for Torque Required to Open and Close Closures on Glass Containers

ASTM D3198 defines the torque measurement needed to open and close closures on glass containers. As glass remains a common packaging material, especially in the food and beverage sectors, ensuring the correct closure torque is vital for product integrity during handling, transportation, and consumption. The Cap Torque Tester provides precise torque readings in compliance with ASTM D3198, ensuring that glass containers meet required performance standards.

ASTM D3474: Standard Test Method for Torque and Force to Open Closures

ASTM D3474 specifies the procedure for measuring both the torque and force necessary to open closures, particularly for liquid containers. This standard is significant for ensuring that packaging is not only easy to open but also secure enough to protect the product inside. The Cap Torque Tester is equipped to handle both the torque and force measurements in alignment with ASTM D3474, providing critical data for quality control in packaging.

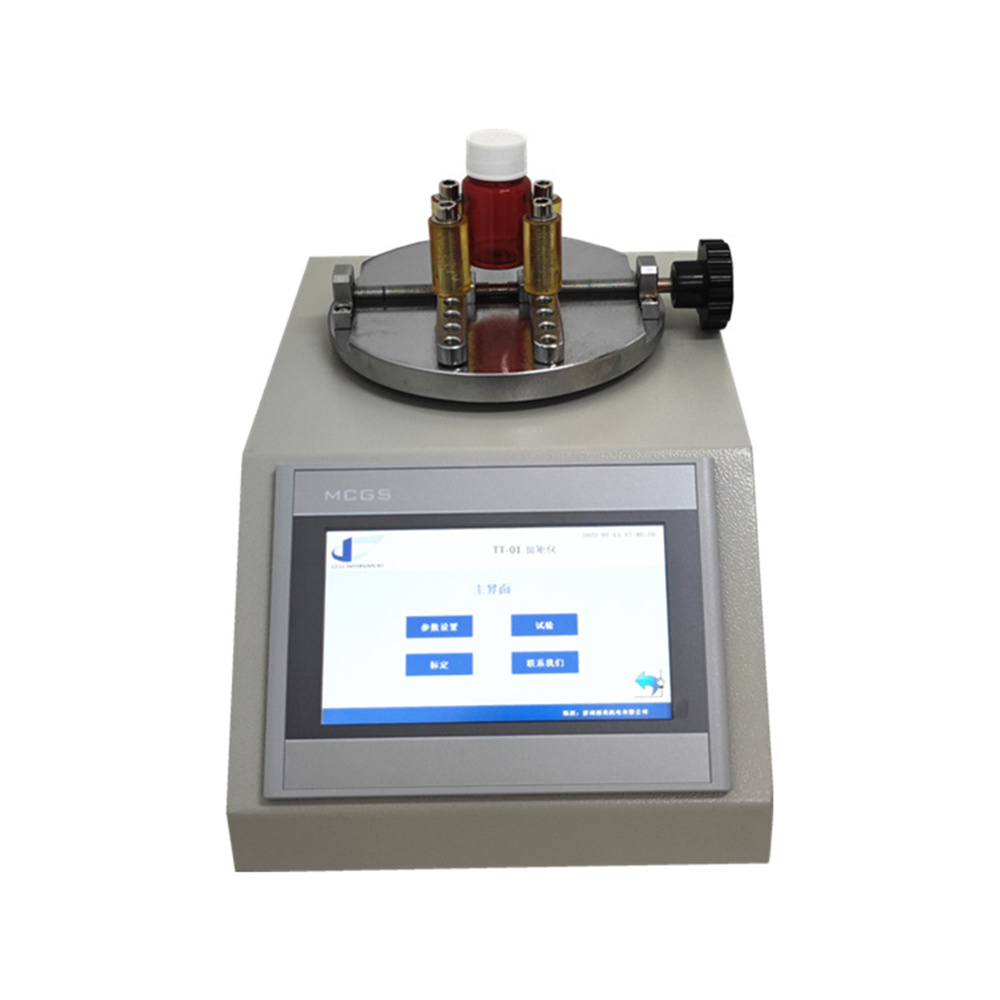

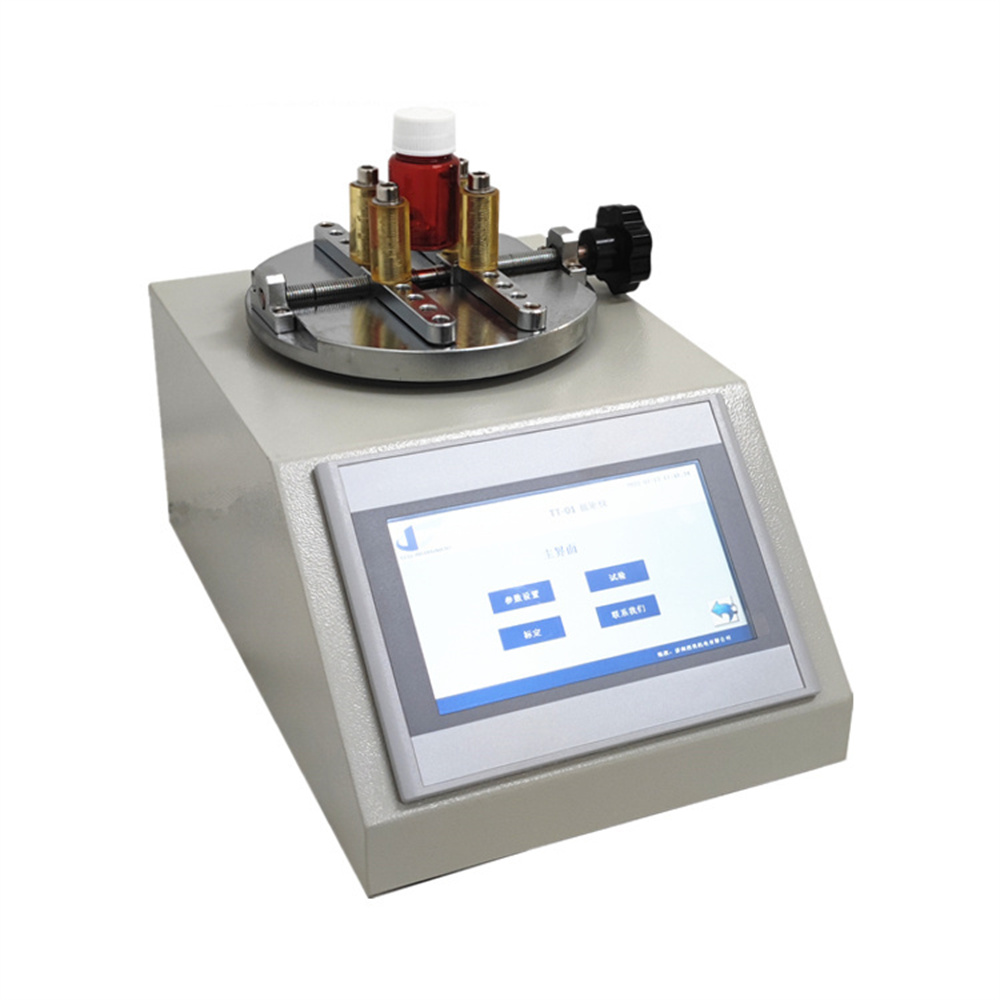

Key Features of the Cap Torque Tester

- Precise Measurement: The tester ensures accurate measurement of both opening and locking forces, essential for determining the performance of bottle caps and closures.

- Stable and Reliable: Known for its industrial-level stability, the Cap Torque Tester ensures repeatable and reliable test results, even with varying cap sizes.

- Multiple Units of Measurement: Display torque results in a variety of units, including Kgf.cm, N.cm, daN.cm, Inch.lbs, and N.m, to suit international testing standards and preferences.

- User-Friendly Interface: The intuitive HMI touchscreen interface makes operation simple and efficient, with an optional micro-printer for easy data logging and documentation.

- Overload Protection: The tester is equipped with overload protection, safeguarding both the equipment and the operator from excessive force during testing.

- Extended Clamp Range: Accommodates a wide range of packaging sizes, with clamp ranges from Φ5mm to Φ170mm, making it versatile for various bottle types.

- RS232 and Software Integration: Equipped with an RS232 port for data transfer and optional professional software integration for advanced analysis and reporting.

Test Process: How the Cap Torque Tester Works

- Sample Setup: Place the bottle cap into the fixed clamp of the tester.

- Manual Operation: The user manually opens or locks the cap, applying force to measure the torque values.

- Torque Measurement: The sensor connected to the clamp captures the torque applied, measuring the force required for both opening and closing the cap.

- Data Recording: The tester automatically stores peak values and displays them on the touchscreen for easy interpretation and analysis.

Why Choose the Cap Torque Tester?

- Accuracy and Precision: Provides highly accurate readings, essential for the quality control and performance validation of cap designs.

- Compliance with Key Industry Standards: Meets essential testing standards like ASTM D2063, ASTM D3198, and ASTM D3474, ensuring regulatory compliance in industries such as pharmaceuticals and food packaging.

- Versatile for Multiple Packaging Types: Ideal for testing various closures, including PET bottles, medicine bottles, spout bags, and flexible tube packages.

- Efficient and Durable: Designed for high-performance testing with built-in overload protection, data retention, and an intuitive user interface to improve testing efficiency.

The Cap Torque Tester is a critical tool for manufacturers across various industries, including pharmaceuticals, food and beverage, and consumer goods. By providing precise torque measurements and ensuring compliance with key standards such as ASTM D2063, ASTM D3198, and ASTM D3474, this tester ensures the safety, functionality, and ease of use of packaging. With its versatile design, reliability, and high degree of accuracy, the Cap Torque Tester helps manufacturers optimize their production processes, improve quality control, and meet the highest industry standards.