Introduction to Tear Testing

Tear resistance, also referred to as tear strength, is a crucial mechanical property that measures how well a material can resist tearing forces. This property is essential in industries where material durability is critical, such as packaging, textiles, medical device packaging, and more. The tear testing machine is a vital tool for manufacturers to assess the tear resistance of a wide range of materials. This test provides valuable data to ensure products meet performance standards, ensuring they can withstand forces encountered during handling, transportation, and use.

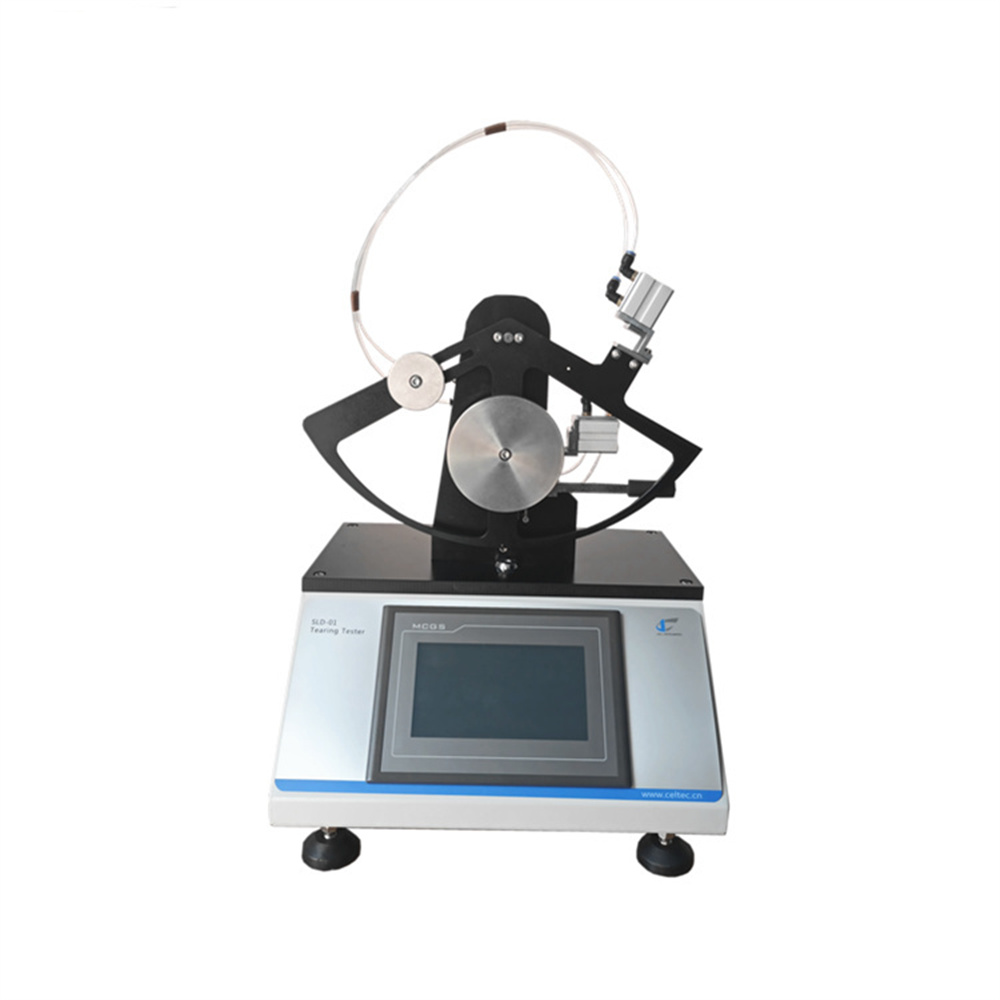

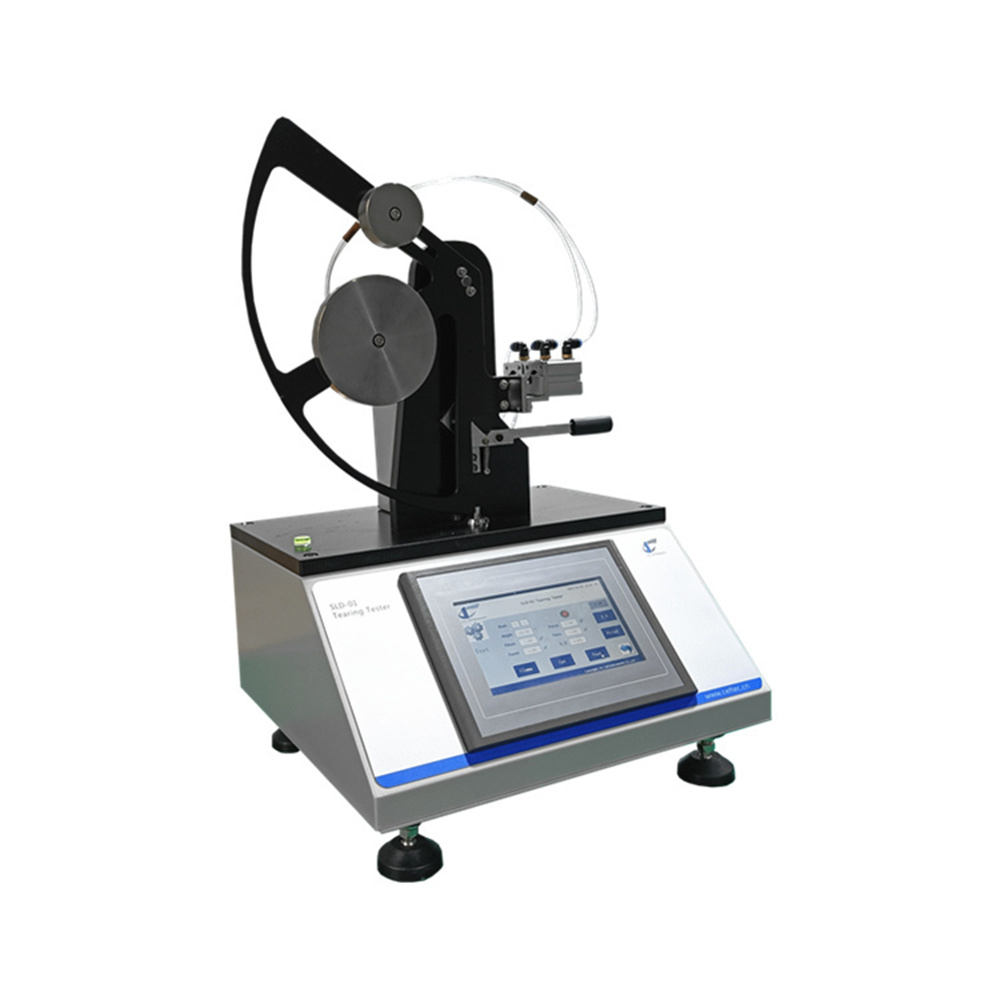

The SLD-01 Tear Tester is designed to offer accurate and reliable measurement of tear strength in materials such as paper, plastic films, textiles, and other flexible materials. It is an essential instrument for quality control and material selection in a variety of industries.

What is a Tear Strength Test?

Understanding Tear Strength

The tear strength test measures the force required to propagate a tear through a material. This test helps determine the material’s ability to withstand tearing forces, providing valuable insight into its durability and performance. Tear strength is especially important for packaging materials, textiles, and medical packaging, where material failure could compromise the integrity of the product or safety.

In this test, a sample material is subjected to a controlled force to propagate a tear, and the energy required to propagate that tear is used to determine the tear strength. The tear testing machine is designed to measure this force with high precision, ensuring that manufacturers can reliably assess the material’s tear resistance.

Key Standards for Tear Testing Machines

The tear testing machine is designed to meet several internationally recognized standards, ensuring consistency and reliability in test results. Below are some of the most important standards for tear resistance testing:

ASTM D1922 – Standard Test Method for Propagating Knife Test

ASTM D1922 is one of the most commonly used standards for measuring tear resistance in paper and plastic films. This standard outlines a test method where a pendulum device is used to initiate and propagate a tear in the material.

- Test Method: The sample is slitted, and the pendulum is released to propagate the tear. The energy required to propagate the tear is measured and used to determine the tear resistance.

- Material Focus: Primarily used for paper and plastic films.

- Relevance: Widely used in packaging and other industries to evaluate the tear resistance of materials.

ASTM D1424 – Standard Test Method for Tear Resistance of Paper and Paperboard

ASTM D1424 is a standard that measures the tear resistance of paperboard materials. This test is often used in the packaging industry to evaluate the strength of cardboard boxes and other paper products.

- Test Method: The pendulum tear test is used to measure the force required to propagate a tear through the material.

- Material Focus: Paper and paperboard materials.

- Relevance: Critical for testing packaging materials, especially in the production of cardboard packaging.

ASTM D689 – Standard Guide for Paper and Paperboard Tear Test Methods

ASTM D689 provides a guide for selecting tear test methods for paper and paperboard materials. This standard is especially useful when different tear testing methods are available and helps users choose the most appropriate test based on material type and application.

- Test Method: Provides guidance on selecting the most suitable tear testing method.

- Material Focus: Paper and paperboard materials.

- Relevance: Helps ensure that manufacturers select the correct testing method for their materials.

ISO 6383 – Plastic Film and Sheeting: Determination of Tear Resistance

ISO 6383 specifies a method for measuring the tear resistance of plastic films and sheeting. This standard is critical for assessing the durability of plastic packaging materials, which must withstand stresses during handling and use.

- Test Method: The test involves using a pendulum tester to measure the tear strength of plastic films.

- Material Focus: Plastic films and sheeting.

- Relevance: Essential for testing tear resistance in plastic packaging.

ISO 1974 – Plastics: Film and Sheeting – Determination of Tear Resistance by Pendulum Method

ISO 1974 provides a standardized method for measuring the tear resistance of plastic films and sheets, similar to ASTM standards but with a global focus. This test is used to ensure that plastic films meet international quality standards for tear resistance.

- Test Method: A pendulum tear test is used to measure the energy required to propagate a tear through the plastic film.

- Material Focus: Primarily used for plastic films and sheets.

- Relevance: Important for manufacturers of plastic packaging and film products.

Test Process for Tear Testing Machine (SLD-01 Tear Tester)

How the SLD-01 Tear Tester Works

The SLD-01 Tear Tester uses a precise pendulum mechanism to determine the tear resistance of materials. Here’s how the process works:

- Sample Preparation: A slit is made in the material, typically 43mm from the edge.

- Pendulum Release: The pendulum is released from a fixed height and propagates the tear through the material.

- Measurement: The energy lost by the pendulum is measured and used to calculate the average force required to propagate the tear, giving an accurate measurement of the material’s tear strength.

This process is fully automated and controlled by a PLC system, ensuring consistency and accuracy for each test.

Technical Features of the SLD-01 Tear Tester

- PLC Control and HMI Touch Screen: The tester is equipped with an industrial-grade programmable logic controller (PLC) and a human-machine interface (HMI) touch screen for precise control and ease of operation.

- Wide Test Range: Accommodates various materials, from thin films to thick paperboard, with customizable settings for different materials.

- Pneumatic Specimen Clamping: Ensures secure and consistent gripping of the sample for reliable test results.

- Automatic Data Collection: Automatically collects test data and stores the results for analysis.

- Microprinter: Includes a built-in microprinter for immediate printouts of test results.

- RS-232 Port and Optional Software: Allows data export and advanced analysis with optional software for comprehensive reporting.

Application Areas for the Tear Testing Machine

- Packaging Industry: Ensures that packaging materials, such as paper, plastic films, and cardboard, meet durability standards.

- Medical Device Packaging: Assesses tear resistance of packaging materials used in medical applications to guarantee protection and safety.

- Textiles: Tests fabrics for tear strength to ensure they are suitable for garments, upholstery, and other applications.

- Food and Beverages: Validates tear resistance in packaging materials that protect food and beverage products from contamination and damage.

The tear testing machine is an essential tool for industries that rely on the durability of materials. Whether you’re testing paper, plastic films, or textiles, the SLD-01 Tear Tester offers accurate and repeatable results that ensure materials meet the necessary quality standards. Conforming to industry standards like ASTM D1922, ASTM D1424, ASTM D689, ISO 6383, and ISO 1974, this tester is ideal for manufacturers who need reliable tear resistance data for their products. Ensure your materials meet performance standards and deliver high-quality products with the SLD-01 Tear Tester.

FAQ

1. What materials can the tear testing machine be used to test?

The tear testing machine can be used to test materials such as paper, cardboard, plastic films, textiles, and other flexible materials.

2. How does the tear strength test work?

The tear strength test involves creating a small slit in the material and using a pendulum mechanism to propagate the tear. The energy lost by the pendulum is measured and used to calculate the tear resistance.

3. What is ASTM D1922, and why is it important?

ASTM D1922 is a standard test method for measuring the tear resistance of paper and plastic films. It ensures that packaging materials meet the required durability standards for real-world use.

4. How does the SLD-01 Tear Tester differ from other tear testers?

The SLD-01 Tear Tester features a PLC control system, wide test range, pneumatic specimen clamping, and automatic data collection, making it more efficient and precise compared to other models.

5. Can the tear testing machine be used for medical packaging materials?

Yes, the tear testing machine is ideal for testing medical packaging materials to ensure they meet the necessary durability and safety standards required for medical products.