Introduction to Tissue Thickness and Tissue Thickness Gauge Test Methods

Tissue thickness is a key quality attribute for tissue paper products, influencing their strength, absorbency, and softness. Accurate measurement of tissue thickness is crucial for manufacturers to ensure product consistency and compliance with industry standards. Thickness testing is especially important for tissue products used in packaging, medical, and consumer goods applications.

Tissue thickness testing involves measuring the distance between two principal surfaces of tissue products under a specified pressure. The results provide insights into the bulkiness, strength, and quality of tissue papers, which directly impact their performance in various applications, such as napkins, facial tissues, and kitchen roll papers.

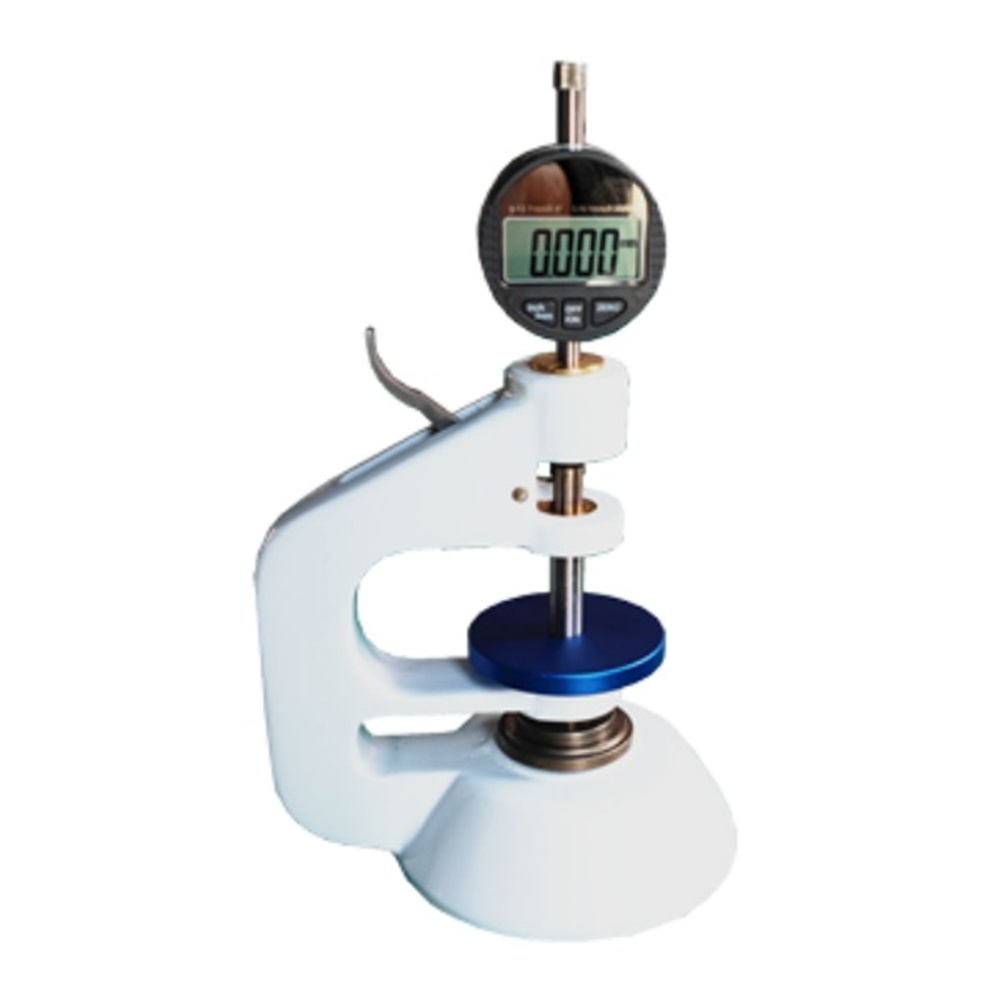

The THD-01 Tissue Thickness Gauge: Product Overview

The THD-01 Tissue Thickness Gauge is a precision instrument designed to measure the thickness and bulking thickness of tissue products such as napkins, paper towels, handkerchiefs, and other tissue-based products. It uses a standardized pressure of 2KPa to ensure accurate and consistent measurements of both single-layer and laminated tissue sheets. The device is ideal for quality control and research applications in the tissue paper manufacturing industry.

How Does the THD-01 Tissue Thickness Gauge Work?

The THD-01 Tissue Thickness Gauge works on the principle of measuring the thickness of tissue paper by applying a consistent pressure of 2KPa between two parallel, flat surfaces. The sample is placed between the lower fixed reference plate and a moveable upper pressure-foot. The pressure-foot exerts a 2KPa load, ensuring standardized testing conditions. The device then measures the distance between the surfaces to determine the tissue’s thickness.

This method ensures accuracy in the measurement of tissue products during production and for finished goods, providing reliable data for product quality assessment.

Key Features and Benefits

-

Precision and Accuracy

- Resolution: 0.001mm for highly accurate thickness measurements.

- Indication Error: ±0.05% to ensure precise readings with minimal deviation.

-

Consistent Testing Conditions

- Contacting Pressure: Maintains a pressure of 2.0 ± 0.1 KPa, ensuring that all samples are measured under the same standardized pressure.

- Test Speed: The measuring speed is controlled at 2.0 ± 0.2 mm/s, ensuring consistent and repeatable test results.

-

Versatility

- The THD-01 Tissue Thickness Gauge can test a wide variety of tissue products, including both single-ply and multi-ply sheets, as well as laminated and unlaminated tissue materials.

-

Ease of Use

- The gauge is simple to operate, with a user-friendly interface and clear measurement display, making it suitable for both laboratory and production floor applications.

Technical Data

| Test Range | 0~4 mm |

| Resolution | 0.001mm |

| Contact Area | 1000±20 mm² |

| Contact Pressure | 2±0.1 kPa |

| Surface parallelism | ≤0.001mm |

| Indication error | ±0.05% |

Test Methods and Standards

Measurement Principle

The THD-01 Tissue Thickness Gauge measures the thickness of tissue paper by applying a constant 2KPa pressure between two parallel surfaces. The sample is placed on the fixed lower face, and the upper, circular pressure-foot is moved downward, exerting the specified load. The distance between the two surfaces is then recorded as the tissue thickness.

This method is consistent with standard testing procedures used in the tissue paper industry to ensure accurate and repeatable results.

Relevant Standards for Tissue Thickness Testing

- ISO 12625-3: Standard for tissue paper testing, including thickness measurements.

- TAPPI T401: Standard test method for measuring paper and paperboard thickness.

- ASTM D1777: Standard test method for the thickness of paper and paperboard, ensuring consistency in material testing.

Application Areas

The THD-01 Tissue Thickness Gauge is essential for industries that manufacture tissue paper products, including:

- Tissue Paper Manufacturers

Ideal for testing the thickness of various tissue products such as paper towels, napkins, facial tissues, and kitchen roll papers. - Quality Control and Research

Used in laboratories and production facilities for quality assurance, research, and development, helping manufacturers ensure the consistency and performance of tissue products. - Packaging and Consumer Goods

The THD-01 is also valuable for manufacturers of tissue-based packaging materials, ensuring the thickness and quality of tissue used in packaging applications.

Frequently Asked Questions (FAQ)

- What is single-ply thickness?

Single-ply thickness refers to the distance between the two principal surfaces of a single ply of tissue paper, measured under a static load of 2KPa. A “ply” of tissue is an unlaminated sheet of tissue. - What is single-sheet thickness?

Single-sheet thickness is the distance between the two principal surfaces of a single sheet of tissue product (whether laminated or unlaminated), measured under the applied static load of 2KPa. - What is bulking thickness?

Bulking thickness refers to the thickness of a single sheet of tissue paper or tissue product, calculated by measuring the thickness of several superimposed sheets under a 2KPa static load. - How does the THD-01 Tissue Thickness Gauge ensure accurate results?

The THD-01 ensures precise and repeatable results by applying a consistent pressure of 2KPa, using high-precision sensors for measurement, and offering a resolution of 0.001mm to detect even the smallest changes in tissue thickness. - Can the THD-01 Tissue Thickness Gauge be used for multi-ply tissue?

Yes, the THD-01 can be used to measure both single-ply and multi-ply tissue products, providing accurate thickness measurements for a wide range of tissue materials, including laminated and unlaminated sheets.