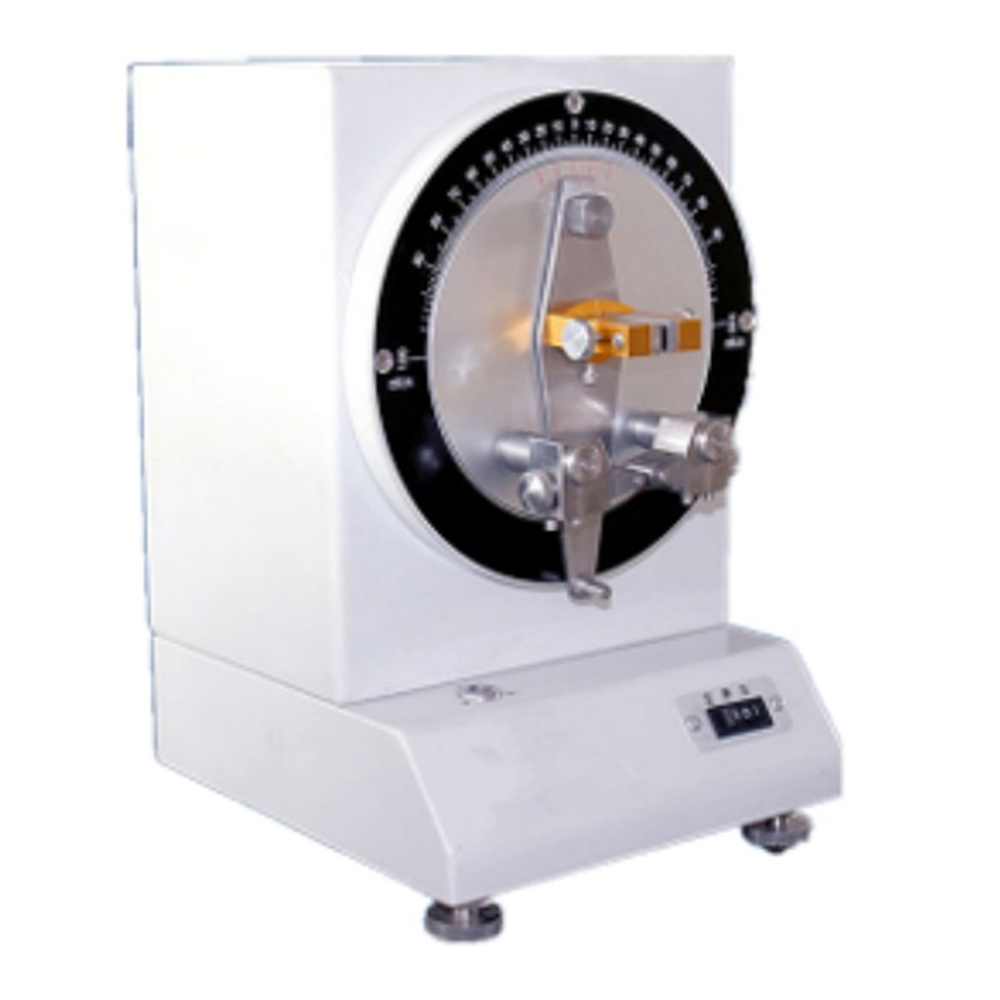

The Taber Stiffness Tester is an essential tool designed to evaluate the bending resistance of paper, paperboard, and other high-grammage materials. With applications across industries like packaging, medical devices, electronics, and quality inspection, this instrument helps manufacturers ensure product durability and structural integrity. The Taber Stiffness Tester provides accurate, reliable measurements, making it ideal for quality assurance processes where precise stiffness data is critical.

Applications of the Taber Stiffness Tester

The Taber Stiffness Tester is widely used for measuring stiffness in materials that require strong resistance to bending, such as packaging materials, labels, and structural layers in electronics and medical devices. With its ability to accurately assess the bending strength of materials, it aids industries in ensuring compliance with performance standards, product longevity, and consistency in packaging quality.

Testing Principle and Measurement Process

The Taber Stiffness Tester operates by clamping a test sample and bending it through a predetermined angle to measure the resulting bending moment. The bending moment, expressed in millinewton meters (mN·m), directly reflects the material’s stiffness. For general materials, a 15° angle is standard, while a 7.5° angle is available for sensitive materials prone to permanent deformation at larger angles. The Taber Stiffness Tester’s design ensures precise bending length and speed, guaranteeing consistent results for quality control and research purposes.

Key Standards Compliant with Taber Stiffness Testing

The Taber Stiffness Tester meets multiple industry standards, ensuring versatility and reliability in various testing environments:

- ASTM D5342: This standard is widely used to measure the stiffness of paper and paperboard, offering valuable insights into the material’s bending resistance and suitability for packaging.

- ASTM D5650: Specifies requirements for testing the stiffness of high-grammage paper products, commonly used in industrial and consumer goods packaging.

- ASTM D3301: Defines the methods for measuring bending resistance in different grades of paper, aiding manufacturers in achieving quality consistency.

- BS ISO 2493.2 & ISO 2493.2: These standards apply to bending stiffness measurement on a global scale, providing a benchmark for international quality.

- JIS P8125.2: Used in Japanese industries, this standard offers specific guidelines for stiffness testing in paper-based products.

- TAPPI T489: A North American standard frequently referenced in the paperboard industry, particularly in packaging.

- TAPPI T566: This standard outlines test methods for flexibility and stiffness in high-grammage materials, ensuring durability in packaging applications.

Main Technical Specifications

| Test range | 1~500 mN.m (in 7 ranges) |

| Indication error | ±2% |

| Bending length | 50mm±0.1mm |

| Testing speed | (200°±20°)/min |

| bending angle | 15°±0.3° and 7.5°±0.3° |

| Sample size | 38*70 mm |

| Dimension | 220*230*350mm |

| Net weight | 15kg |

| Power | AC 220V 50Hz |

Advantages of Using the Taber Stiffness Tester

- High Accuracy: With an error margin of only ±2%, the Taber Stiffness Tester provides reliable and precise measurements for quality control.

- Standards Compliance: Meeting ASTM, ISO, JIS, and TAPPI standards, it serves a broad range of regulatory needs, making it adaptable to various industries.

- User-Friendly Design: Adjustable bending angles and compact size make it easy to integrate into laboratory and production settings.

How the Taber Stiffness Tester Enhances Quality Control

By measuring the bending resistance of packaging materials and other high-grammage products, the Taber Stiffness Tester helps manufacturers ensure their products meet industry standards for durability and structural integrity. This instrument plays a crucial role in quality control across packaging, food, medical, and consumer goods industries, allowing companies to uphold product quality and performance.

FAQs

Q1: What materials can be tested with the Taber Stiffness Tester?

The Taber Stiffness Tester is designed for high-grammage paper, paperboard, and similar materials used in packaging and structural applications.

Q2: How is bending resistance expressed in test results?

The bending resistance is recorded as a bending moment, which is measured in millinewton meters (mN·m).

Q3: What is the difference between the 15° and 7.5° bending angles?

The 15° angle is standard for most materials, while the 7.5° angle is used for materials that could deform if bent at larger angles.

Q4: Which standards does this tester comply with?

The Taber Stiffness Tester is compliant with ASTM D5342, ASTM D5650, ASTM D3301, BS ISO 2493.2, ISO 2493.2, JIS P8125.2, TAPPI T489, and TAPPI T566.

Q5: What industries commonly use the Taber Stiffness Tester?

Industries such as packaging, pharmaceuticals, food, electronics, and quality inspection frequently use the Taber Stiffness Tester to ensure product integrity.