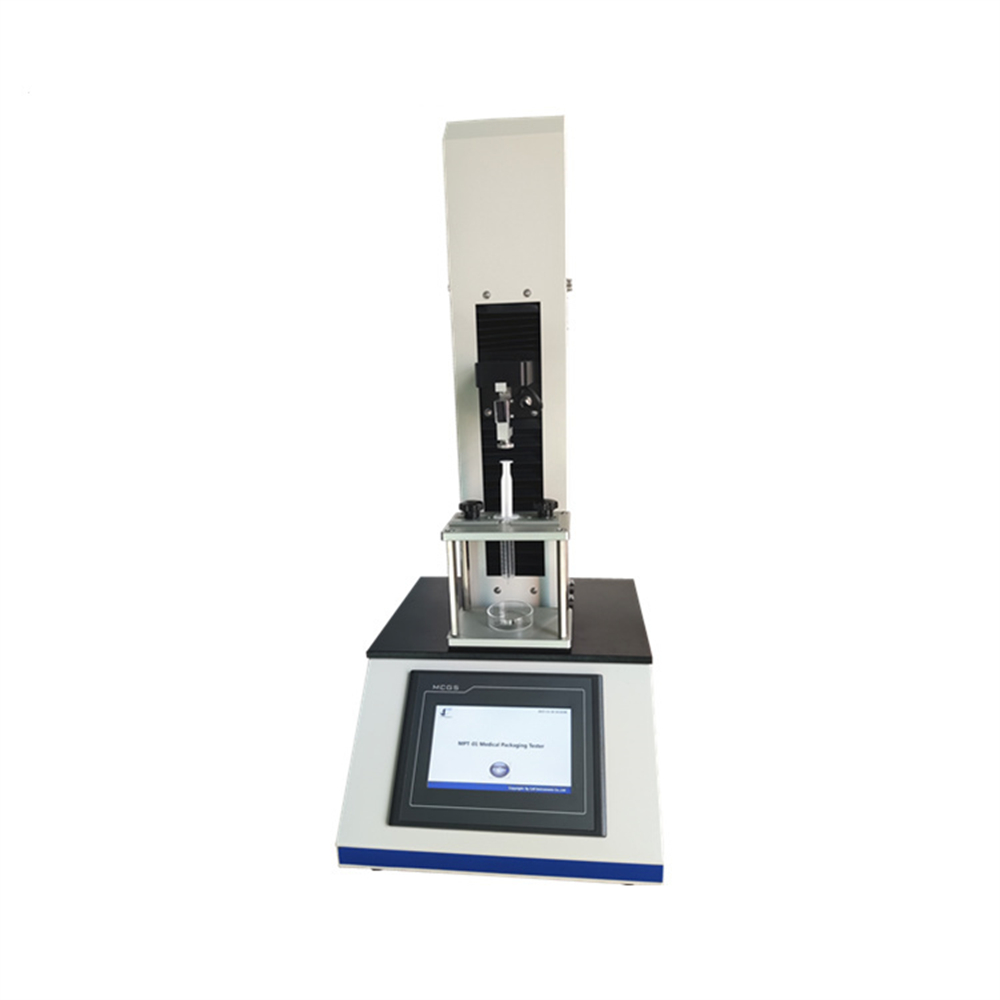

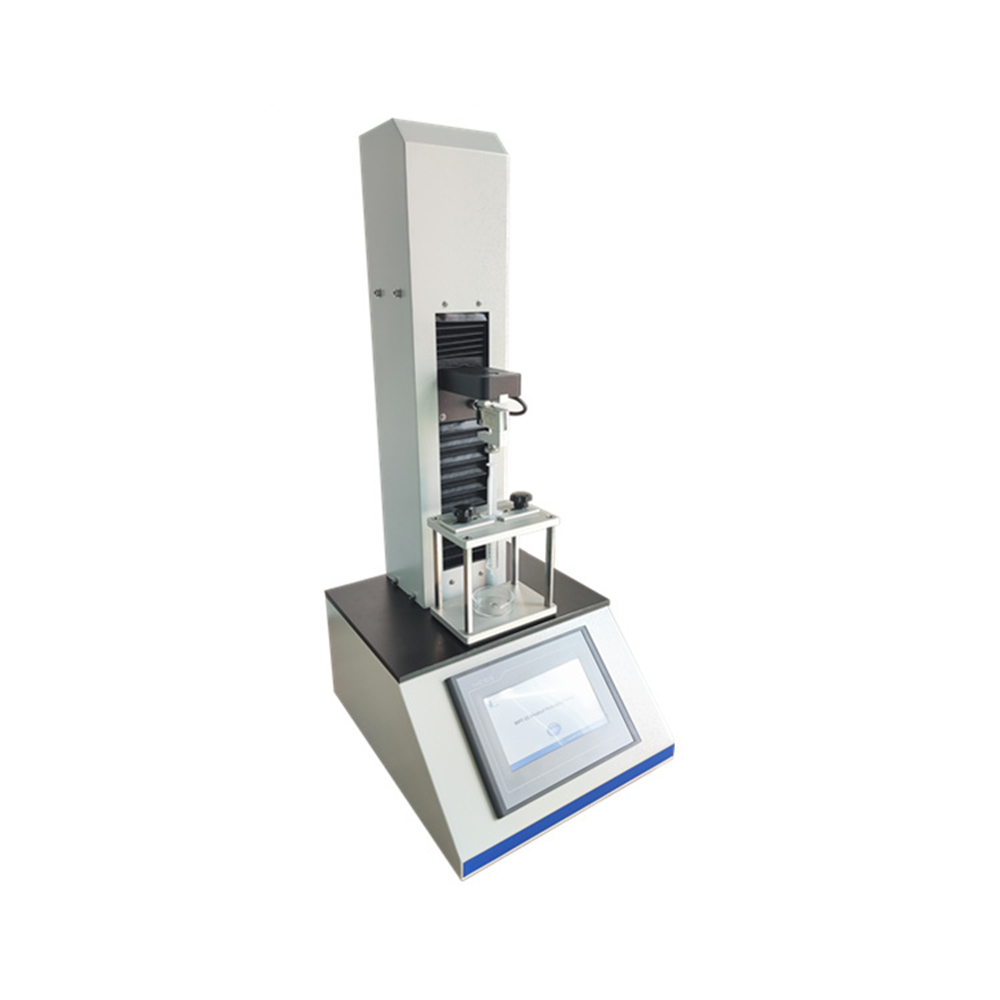

The Syringe Plunger Glide Force Tester is a specialized instrument designed to measure the force required to operate the plunger in hypodermic syringes, ensuring the quality and safety of medical devices used in patient care. With a focus on precision and compliance with industry standards, this tester is indispensable in medical packaging and pharmaceutical testing, offering accurate assessments of syringe performance. By determining key metrics such as plunger glide force and piston glide force, this instrument is essential for manufacturers aiming to meet regulatory requirements and deliver safe products to end-users.

ISO 7886-1 Compliance and Its Importance

The Syringe Plunger Glide Force Tester is fully compliant with ISO 7886-1, an international standard governing the design and testing of sterile, single-use hypodermic syringes. ISO 7886-1 specifies the methods for evaluating syringe functionality, including glide force measurement, to guarantee the syringe’s usability and performance under varied conditions. Testing in accordance with ISO 7886-1 not only helps ensure user safety but also aids manufacturers in meeting regulatory standards essential for market approval.

Versatile Testing Methods

This Syringe Plunger Glide Force Tester offers a variety of test methods to evaluate multiple aspects of syringe performance, including but not limited to:

- Piston Glide Force Measurement: Precisely measures the force required to operate the syringe plunger, critical for ensuring a smooth and consistent glide.

- Syringe Sliding Resistance Test: Evaluates the resistance during plunger movement to assess friction levels and ensure optimal functionality.

- Liquid Leakage Test: Under compression, this test identifies any leaks at the plunger stopper, verifying the syringe’s integrity when subjected to pressure.

- Needle Penetration Test: Determines the force needed for the needle to penetrate, supporting safe and effective syringe use.

- Plunger Pull-Out Test: Measures the force required to pull out the plunger, testing the syringe for structural resilience and user safety.

These tests provide a comprehensive understanding of the syringe’s mechanical properties, ensuring reliability and safety in its end-use application.

Wide Applications Across Industries

The Syringe Plunger Glide Force Tester is widely used across industries such as:

- Medical Packaging: Ensures that syringes meet necessary mechanical standards.

- Pharmaceutical Testing: Validates syringe performance, helping pharmaceutical companies guarantee product quality.

- Quality Inspection Agencies: Provides regulatory assurance by confirming that medical syringes comply with safety standards.

Through these applications, the tester supports quality control efforts, giving manufacturers and regulatory bodies confidence in syringe functionality and safety.

Key Benefits

- Multi-Functional Testing: Embedded with multiple test programs in a single machine, this device is cost-effective and versatile for varied quality assurance tasks.

- User-Defined Program Design: Customized testing programs are available to meet specific user requirements, accommodating various syringe types and sizes.

- Standard-Conforming Processes: Testing processes strictly align with ISO standards, promoting reliable and consistent results across batches.

- Flexibility for Diverse Medical Materials: Adaptable to the unique needs of medical-grade testing, enhancing its usability for a broad range of medical applications.

Advanced Technical Features

The Syringe Plunger Glide Force Tester integrates state-of-the-art technical features to ensure accuracy and ease of use:

- PLC Control Unit: Ensures precise control and monitoring of all testing parameters, offering reliable and repeatable test results.

- 7-Inch HMI Touch Screen: Provides a user-friendly interface, allowing operators to set and monitor tests with ease.

- Precision Ball Screw Mechanism: Enhances speed and displacement accuracy for reliable test conditions.

- Variable Test Speed: Adjustable from 1 to 500 mm/min, allowing for a customized approach depending on test requirements.

- Safety Features: Includes position restrictors, overload protection, and an automatic return function to prevent damage and ensure operator safety.

Customizable Clamps for Specialized Testing

The Syringe Plunger Glide Force Tester features customizable clamps made on demand to fit a range of syringe designs. This flexibility allows users to adapt the device to various configurations, ensuring that every test is accurate, relevant, and reliable.

Main Parameters

| Parameter | Specification |

|---|---|

| Test Range | 50N (customizable as needed) |

| Stroke | 200mm (without clamp) |

| Test Speed | 1~500 mm/min |

| Displacement Accuracy | 0.01 mm |

| Overall Accuracy | 0.5% F.S. |

| Output Options | Screen, Microprinter, RS232 (optional) |

| Power Supply | 110~220V |

FAQs

- What is the purpose of the Syringe Plunger Glide Force Tester?

- It measures the force required to move the syringe plunger, ensuring it meets quality standards for smooth operation and patient safety.

- How does this tester comply with ISO 7886-1?

- The tester adheres to ISO 7886-1 requirements, offering standardized test methods to verify syringe performance and usability.

- Can the tester accommodate different syringe designs?

- Yes, the tester includes customizable clamps that adapt to various syringe designs, enabling flexible testing.

- What types of tests can be performed with this instrument?

- Tests include piston glide force, syringe sliding resistance, liquid leakage, needle penetration, and plunger pull-out.

- How is data output managed?

- Data can be outputted to the screen, microprinter, or RS232 interface, providing multiple ways to record and analyze results.