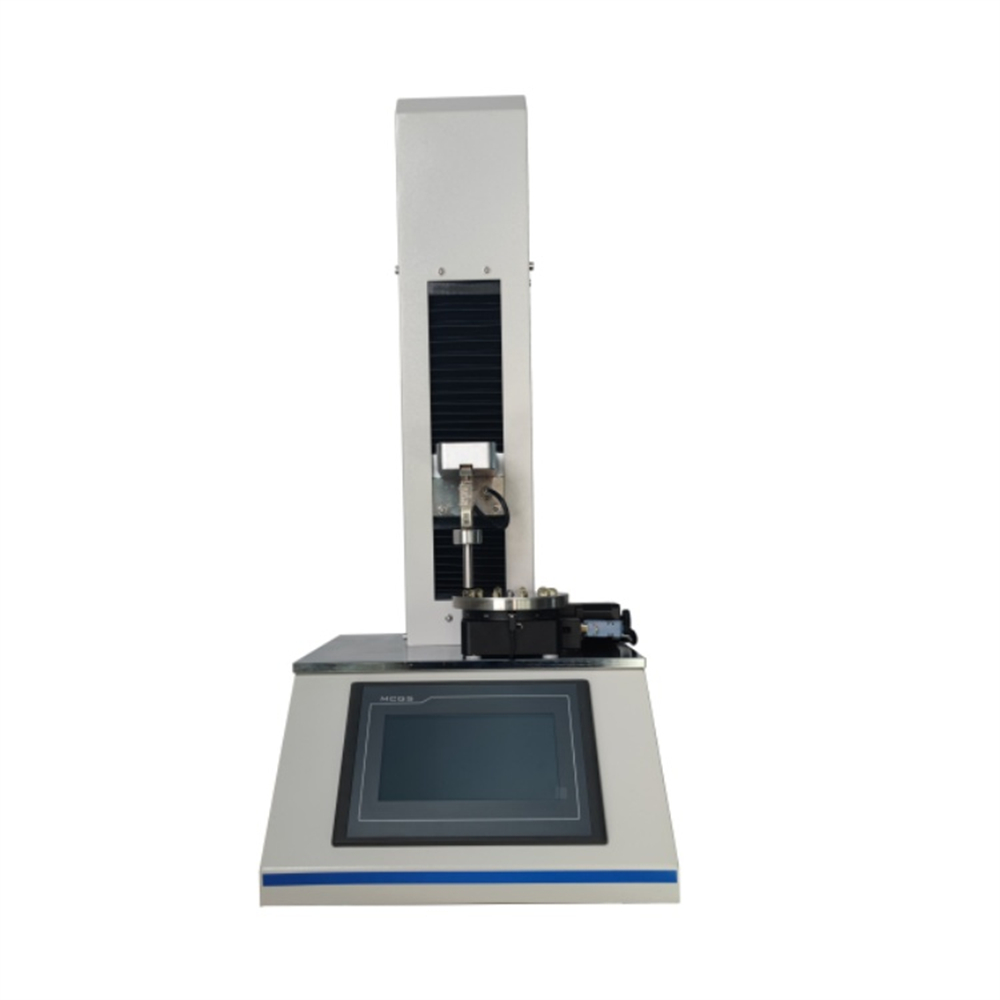

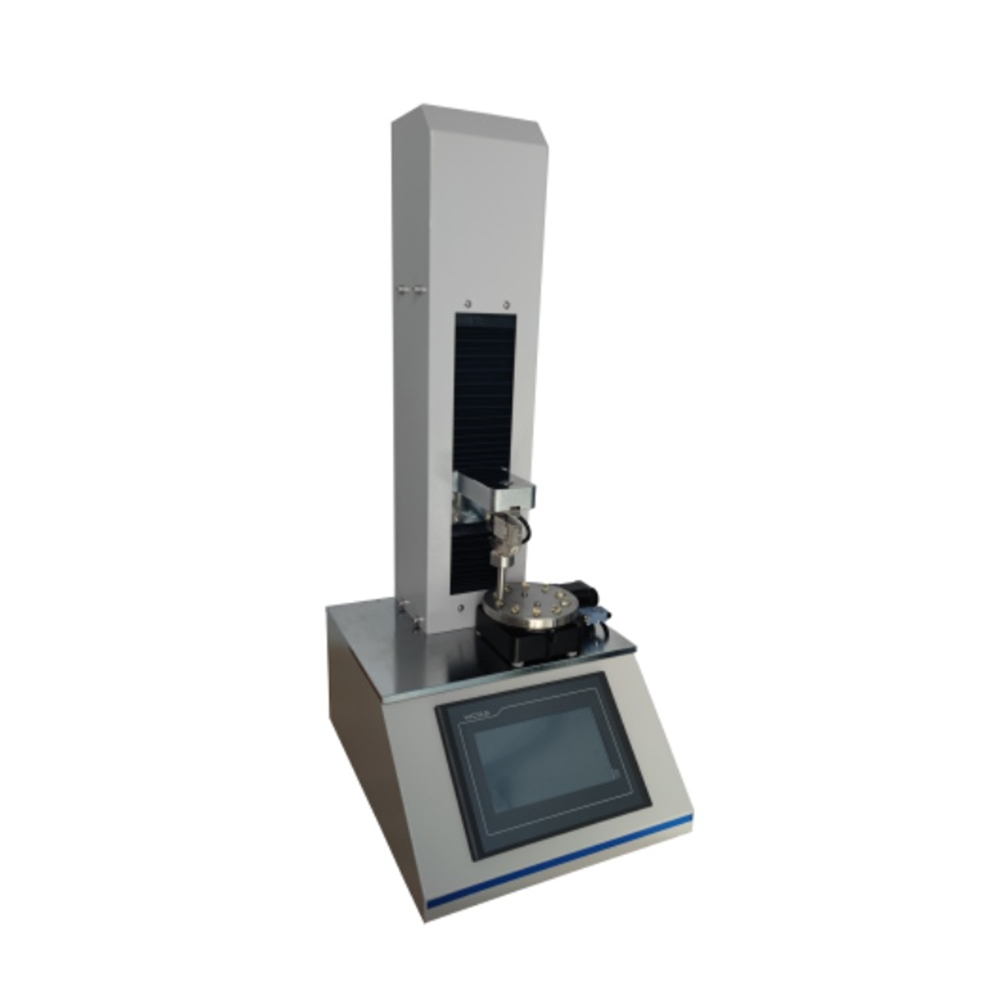

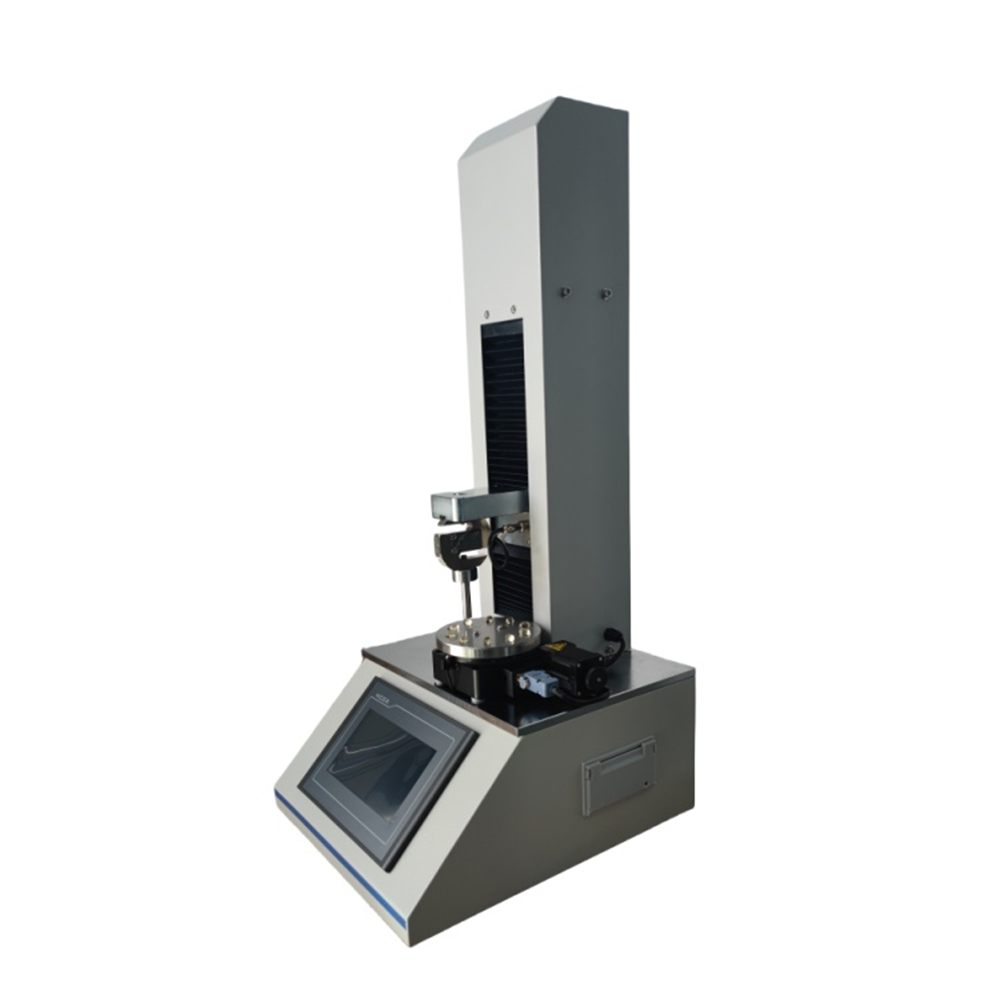

Introduction to the Soft Gel Capsule Hardness Tester

In the pharmaceutical and nutraceutical industries, quality control is paramount. Ensuring that soft gel capsules maintain their structural integrity through packaging, storage, and distribution processes is critical. The Soft Gel Capsule Hardness Tester, specifically the CHT-01 Capsule and Softgel Hardness Tester, is a high-precision instrument designed to measure capsule firmness, resilience, and overall strength. By assessing key factors like hardness, deformation, and seal strength, this tester helps manufacturers guarantee that their products are safe, effective, and high-quality.

Why Test the Hardness and Firmness of Soft Gel Capsules?

Soft gel capsules are widely used to deliver vitamins, minerals, and medications in a stable and protective gelatin shell. For these capsules, maintaining an ideal firmness level is essential—not only for protecting the active ingredients inside but also for ensuring a controlled release of the contents upon ingestion. Hardness testing reveals how the capsule will perform under various conditions, from packaging and transportation to the consumer’s experience. The Soft Gel Capsule Hardness Tester is vital for identifying any weaknesses in capsule walls or seals, preventing issues before they reach the market.

Key Features of the Soft Gel Capsule Hardness Tester

- High Precision Testing Capabilities

Equipped with advanced technology such as a PLC control unit, precision ball screw, and stepper motor, this tester provides reliable and accurate results that support rigorous quality standards. - Versatile Test Programs

Offering multiple standard programs—Force (applying a specific force and measuring distance), Peak (measuring maximum force for capsule rupture), and Distance (measuring force at a fixed distance)—the Soft Gel Capsule Hardness Tester enables comprehensive testing to understand every facet of capsule integrity. - User-Friendly Interface and Control

A 7-inch HMI touch screen allows users to effortlessly configure settings, manage test programs, and visualize results. This intuitive design improves workflow and facilitates quick adjustments based on test requirements. - Enhanced Efficiency and Safety Features

A rotating table, automatic statics for data collection, and overload protection enhance efficiency and safety. These features streamline testing and protect the instrument from overuse, maximizing its lifespan and reliability.

Detailed Test Methods for Soft Gel Capsule Hardness and Firmness

- Compression Test

In the compression test, a 10 mm-diameter or 10mm² surface area cylinder probe applies pressure to the capsule until deformation or rupture occurs. This simulates the physical stresses the capsule might face during real-world conditions, such as packaging and transportation. By testing compression, manufacturers gain insights into the capsule’s durability and resistance to damage. - Firmness and Seal Strength Testing

Firmness testing assesses how much a capsule deforms under a specific compressive load, providing insights into its elasticity and resilience. Additionally, the seal strength test measures the force required to break the capsule’s seal, ensuring it won’t rupture prematurely and will release its contents only under intended conditions.

Technical Specifications and Parameters

| Test Range | 0~200N (Or as required) |

| Stroke | 200mm (without clamp) |

| Speed | 1~300mm/min(or as required) |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~ 220V 50/60Hz |

Benefits of the Soft Gel Capsule Hardness Tester

- Comprehensive Quality Assurance Testing

With multi-test capabilities, this tester enables manufacturers to assess capsules for durability, uniformity, and structural strength. This results in improved product quality and customer satisfaction. - Customizable Fixture Options for Versatile Testing

Offering various fixtures and jigs, the tester accommodates different capsule sizes and shapes, making it versatile for a wide range of soft gel applications. - Built for Long-Lasting Durability

Constructed with robust components and advanced mechanisms, the tester is built to provide a long service life, maximizing return on investment while reducing downtime and maintenance.

Applications of the Soft Gel Capsule Hardness Tester

This instrument is essential in pharmaceutical and nutraceutical production environments, where soft gel capsules containing vitamins, minerals, and other liquid medications require strict quality control. The Soft Gel Capsule Hardness Tester plays a crucial role in quality assurance for manufacturing, packaging, and handling, ensuring capsules maintain their integrity and effectiveness until they reach the consumer.

FAQ Section

- Q1: What types of capsules can be tested with this instrument?

A: The Soft Gel Capsule Hardness Tester is ideal for testing soft gel capsules used in pharmaceuticals and nutraceuticals, including those containing vitamins and liquid medications. - Q2: What is the significance of the firmness test?

A: Firmness testing assesses the capsule wall’s strength and flexibility, helping ensure capsules won’t rupture during normal handling, storage, or packaging. - Q3: Can this tester measure elasticity?

A: Yes, it quantifies capsule elasticity by measuring wall deformation under a specified compressive load, ensuring capsules are flexible yet durable. - Q4: Is the CHT-01 customizable for specific capsule types?

A: Yes, the tester can be customized with various fixtures and jigs to accommodate different capsule shapes and sizes, making it suitable for diverse testing needs. - Q5: What output options are available for data recording?

A: The tester displays data on-screen, allows printouts via a microprinter, and offers optional RS232 connectivity for digital data export.