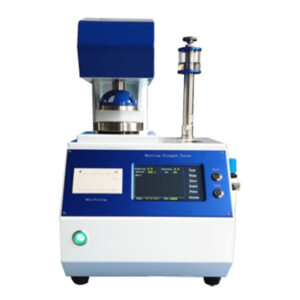

Introduction to the Short Span Compression Tester

The SCT-01 Short Span Compression Tester is a high-precision instrument engineered to evaluate the compressive strength of paper and board, providing essential quality insights for materials used in container and box production. This tester is especially suited for papers and boards with a grammage between 100 g/m² and 400 g/m², ensuring that only materials meeting the required strength levels are approved for manufacturing. With its robust design and advanced features, the SCT-01 helps optimize product durability, making it a valuable tool for quality control across various industries, including packaging, paper manufacturing, and quality inspection agencies.

Key Applications

The SCT-01 Short Span Compression Tester is widely applicable across industries that demand consistent material strength and reliability:

- Packaging Industry: Verifying the quality of materials for box and container production, crucial for transport and storage.

- Paper and Board Manufacturing: Ensuring materials are capable of withstanding stress in both machine and cross-directions, increasing durability.

- Quality Inspection Agencies: Providing a standardized testing method for compliance checks in line with ISO 9895.

System Description of the SCT-01 Short Span Compression Tester

The SCT-01 Short Span Compression Tester is designed with precision clamps and a robust clamping mechanism to ensure accurate testing:

- Clamps: The tester has two clamps, each 30 mm in length, with stationary and movable jaws. These jaws are crafted with a high-friction surface to ensure firm and consistent grip during tests.

- Clamping Force: It applies a steady clamping force of 2300 ± 500 N, securely holding the test piece across its entire width.

- Jaw Alignment: The stationary and movable jaws are parallel, maintaining uniformity across each test and supporting accurate measurements.

- Pneumatic Clamping and Adjustable Test Speed: The tester’s pneumatic clamping system with customizable force and adjustable speed enables flexibility, adapting to various test requirements and material types.

Test Principle of Short Span Compression Testing

The SCT-01 Short Span Compression Tester operates on a straightforward yet reliable test principle:

- A 15 mm-wide test sample is clamped between two jaws that are initially spaced 0.70 mm apart.

- The jaws then compress the test sample until it fails under the applied force.

- The maximum force applied before the compressive failure is recorded, and this value is used to calculate the material’s compressive strength.

This method offers reliable, repeatable results, helping manufacturers determine the material’s strength in real-life application settings.

Overview of ISO 9895 and Its Test Methods

The SCT-01 Short Span Compression Tester meets the ISO 9895 standard, a globally recognized benchmark for assessing the short-span compressive strength of paper and board.

- Introduction to ISO 9895: ISO 9895 specifies procedures for determining compressive strength, guiding the setup and testing process to ensure consistency across different labs and industries.

- Test Method Requirements: ISO 9895 outlines the dimensions of test pieces, specific clamping forces, clamping speed, and calculations for compressive strength, enabling standardized testing for accurate, comparable results.

- Importance of ISO 9895 Compliance: Compliance with ISO 9895 guarantees that the SCT-01 provides dependable, accurate compressive strength measurements, crucial for industries aiming to meet international quality and durability standards.

Benefits of the SCT-01 Short Span Compression Tester

The SCT-01 Short Span Compression Tester offers several advantages that make it an ideal choice for short-span compression testing:

- User-Friendly Operation: Equipped with a PLC control system and HMI for straightforward operation, the SCT-01 minimizes operator error.

- Enhanced Safety Features: Includes an emergency stop button and over-range protection to ensure safe operation.

- Multi-Unit Display Options: Displays test results in multiple units (N, kgf, lbf) for flexibility based on user requirements.

- Advanced Data Management: Features an embedded dot matrix printer for immediate result printing, and an optional RS-232 COM port with software for efficient data transfer and storage.

Technical Specifications of the SCT-01

Below is a summary of the SCT-01’s main technical parameters:

| Parameter | Specification |

|---|---|

| Test Range | 1~500N(0.06~33.3 KN/m) |

| Compression Distance | 0.3~0.7 mm |

| Clamping Length | 30 ± 0.5 mm |

| Test Speed | 3 ± 0.1 mm/min |

| Resolution | 0.01 N |

| Sample Size | 15 mm (width) x 75 mm (length) |

| Gas Pressure Requirement | 0.5 MPa |

| Gas Port Size | Ф6 mm |

| Power Requirement | AC 110~220V, 50Hz |

These specifications ensure the SCT-01 is versatile, accurate, and adaptable, making it ideal for rigorous industrial use.

Compliance and Standards of Short Span Compression Tester

The SCT-01 Short Span Compression Tester is compliant with several standards, enhancing its credibility and relevance in professional settings:

- ISO 9895: Guarantees reliable short-span compressive strength measurements.

- GB/T 2679.10: Provides regional compliance, ensuring compatibility with industry standards in various markets.

Frequently Asked Questions (FAQ)

- What types of materials can be tested with the SCT-01?

- The SCT-01 is suitable for papers and boards within a grammage range of 100 g/m² to 400 g/m², commonly used in packaging and box production.

- How does the SCT-01 ensure accurate compression testing results?

- The SCT-01’s parallel and high-friction jaws, consistent clamping force, and compliance with ISO 9895 standards ensure highly accurate, repeatable test results.

- Why is ISO 9895 compliance important for compression testing?

- ISO 9895 sets global standards for testing methods, ensuring that results are reliable and comparable across industries.

- How does pneumatic clamping improve test accuracy?

- Pneumatic clamping provides consistent pressure across the sample, preventing slippage or damage, which could affect test outcomes.

- What are the benefits of using a multi-unit display and data management software?

- The multi-unit display allows users to view results in different units, while data management software facilitates result analysis and long-term record keeping, enhancing testing efficiency.