Introduction to the Rolling Ball Tack Tester

The Rolling Ball Tack Tester is an essential tool for evaluating the tackiness of pressure-sensitive adhesives (PSAs). It measures the adhesive’s ability to quickly bond with a surface using a straightforward and repeatable test method. This tester is widely used in industries like packaging, medical devices, electronics, and adhesives manufacturing, where consistent adhesive performance is critical. Designed for quality control, the rolling ball tack test ensures precise detection of batch-to-batch variations, making it indispensable for maintaining high product standards.

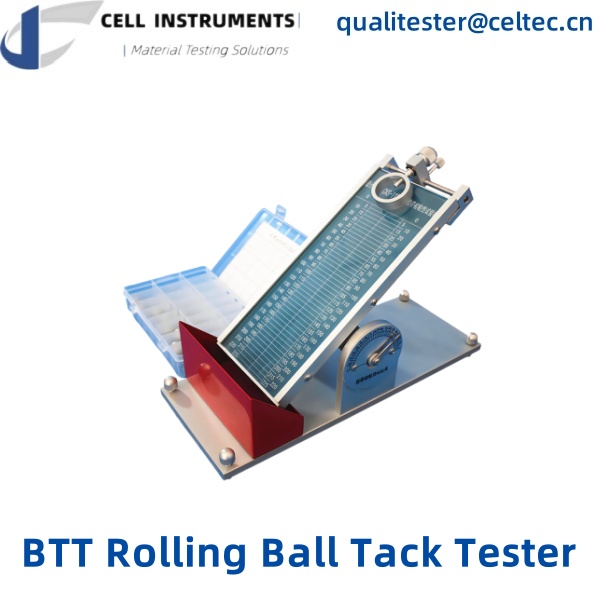

Key Features of the Rolling Ball Tack Tester

- Accurate and Reproducible Results: Designed for laboratory use, offering reliable detection of adhesive variations.

- Two Robust Models:

- BTT-01 Tough Type: Features an inclined trough and release lever to allow a 7/16-inch (11.1 mm) steel ball to roll over the adhesive.

- BTT-02 Inclined Type: Comes with adjustable inclined plates (20°, 30°, or 40°) for flexible testing setups and enhanced versatility.

- Ease of Use: Minimal training required for operation, making it ideal for fast and cost-effective quality control.

Main Parameter

BTT-01

| Trough Length | 6.5 inch |

| Incline Angle | 21.3° |

| Rolling Ball | 7/16 inch (No. 14) |

| Dimension | 210*50*80mm LWH |

| Weight | 0.5kg |

BTT-02

| Inclined Angle | 0~60° |

| Test Area Width | 120mm |

| Rolling Ball | 1/32~1 inch |

| Dimension | 320*140*180mm LWH |

| Weight | 6kg |

Applications of the Rolling Ball Tack Tester

The tester is widely employed in various industries, including:

- Packaging: Ensures labels and seals adhere consistently.

- Adhesives Manufacturing: Confirms the performance of pressure-sensitive adhesive tapes and films.

- Electronics: Evaluates adhesives for device assembly.

- Medical Devices: Verifies adhesive reliability for secure bonding.

Relevant Standards for Rolling Ball Tack Testing

The Rolling Ball Tack Tester complies with the following key standards:

- PSTC-6: Focuses on the comparative tack measurement of adhesives, providing clear guidelines for quality control applications.

- ASTM D3121: Specifies the rolling ball method for determining tack, ensuring reproducibility and precision in adhesive evaluation.

- JIS Z0237: The Japanese Industrial Standard for adhesive tack testing, emphasizing uniformity and accuracy in test results.

These standards establish a robust framework, making the tester a trusted tool for adhesive quality assurance worldwide.

Test Methodology

- Prepare the Adhesive Sample: Secure the adhesive film or substrate on the test surface.

- Set the Inclination Angle: Adjust the inclined plate to the desired angle (20°, 30°, or 40° for BTT-02).

- Release the Ball: Place a steel ball at the top of the incline and release it using the lever or plate.

- Evaluate Tack Performance: Observe the distance traveled by the ball before stopping, indicating the adhesive’s tack strength.

This simple yet effective method ensures consistent and reproducible results, making it ideal for routine quality checks.

Benefits of the Rolling Ball Tack Tester

- Fast and Cost-Effective: A quick method that requires minimal equipment investment.

- Reliable Quality Control: Detects adhesive inconsistencies efficiently, ensuring batch quality.

- Ease of Operation: Straightforward testing process suitable for operators of all experience levels.

- Compliant with Standards: Meets global testing norms like PSTC-6, ASTM D3121, and JIS Z0237.

Why Choose Cell Instruments for Rolling Ball Tack Testing?

As a leading manufacturer of material testing instruments, Cell Instruments provides top-quality solutions tailored to your needs. Our BTT-01 and BTT-02 Rolling Ball Tack Testers are designed to deliver precise results while complying with international standards. With our expertise in customization and automation, we ensure our products meet your specific testing requirements. Trust us to help you maintain high standards in adhesive performance and quality assurance.

FAQs about Rolling Ball Tack Testing

- What is ‘tack’ in the adhesive industry?

- Tack refers to an adhesive’s property to form a bond of measurable strength immediately after contact with minimal pressure.

- How does the rolling ball tack test differ from other tack tests?

- It is a comparative method that evaluates tack by observing how far a rolling ball travels on the adhesive.

- Which industries benefit most from this test?

- Industries like packaging, medical devices, adhesives manufacturing, and electronics rely on this test for quality control.

- What types of adhesives can be tested?

- Most pressure-sensitive adhesives (PSAs), including tapes and films, can be evaluated using this method.

- How do PSTC-6, ASTM D3121, and JIS Z0237 ensure test accuracy?

- These standards provide strict guidelines for test setup, execution, and result interpretation, ensuring reliable and reproducible measurements.