Introduction

In today’s competitive market, ensuring the integrity of packaging is crucial for maintaining product quality and consumer safety. Non-destructive leak testing equipment plays a vital role in achieving this goal. The MLT-01 Micro Leak Tester is designed to provide accurate and reliable leak detection for nonporous, rigid or flexible packages, making it an essential tool in various industries, including pharmaceuticals, food packaging, and medical devices.

Understanding ASTM F2338

What is ASTM F2338?

ASTM F2338 is a critical standard that outlines the testing methods for evaluating the integrity of sealed packages through non-destructive leak testing. This standard ensures that products meet stringent quality and safety criteria, particularly in regulated industries. The methods defined in ASTM F2338 are crucial for identifying potential leakage, which can compromise product integrity and lead to significant financial losses.

Test Methods Defined by ASTM F2338

The ASTM F2338 standard includes several methods for detecting leaks, with a focus on the vacuum decay method. This approach involves applying a negative pressure to the test package and monitoring any pressure increase, indicating a leak. Compared to other leak testing methods, the vacuum decay method is highly sensitive and efficient, making it suitable for various applications.

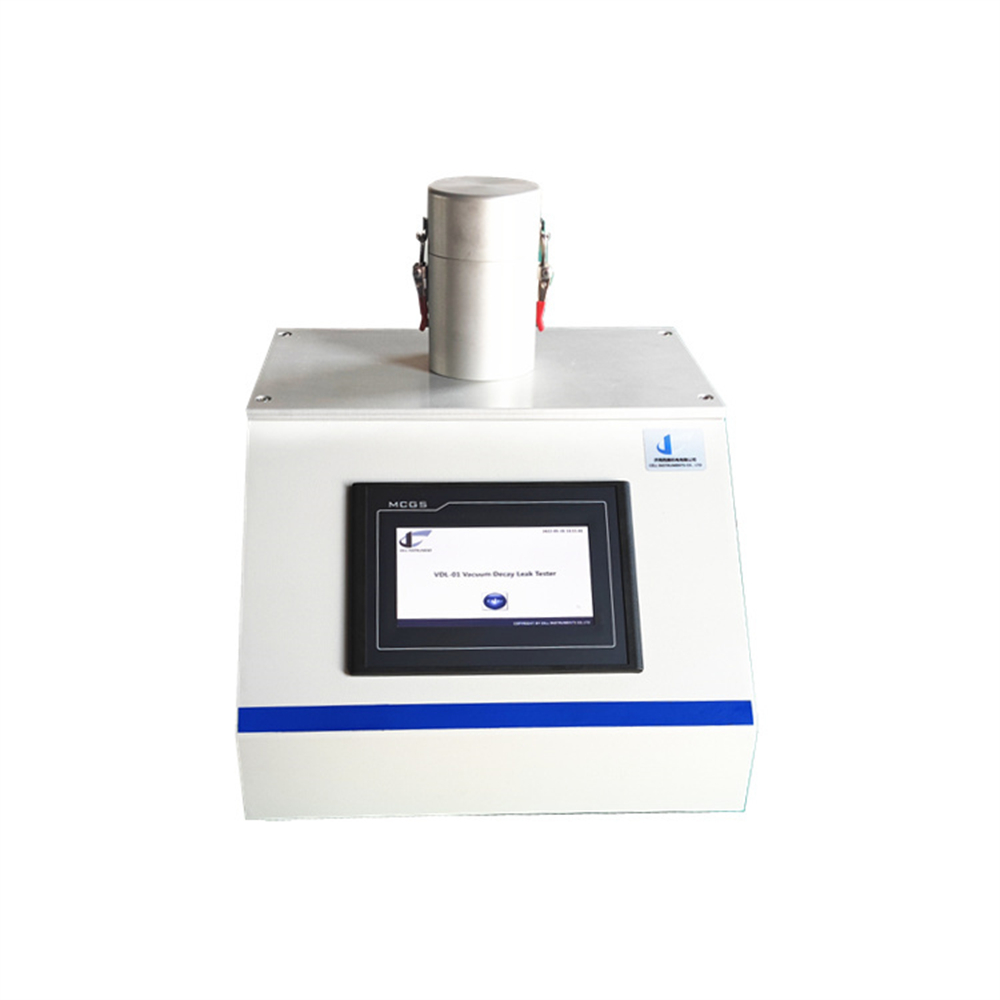

MLT-01 Micro Leak Tester

System Description

The MLT-01 Micro Leak Tester utilizes a sophisticated design that features a network of conduits and valves connecting a test chamber to a high-resolution pressure sensor and an external vacuum source. The system is equipped with a PLC control unit and an HMI touch screen, allowing for intuitive operation. An external gas flow meter ensures optimal system performance, while the specially designed test chamber securely encloses the test package and can incorporate tooling to restrict movement or expansion as needed.

Test Process

The testing process with the MLT-01 Micro Leak Tester consists of four primary stages:

- FILL Stage: Secure the sample in the chamber and apply negative pressure to create a controlled environment.

- SETTLE Stage: Allow the system to accommodate any component stretching or flexing that may occur under negative pressure.

- TEST Phase: Measure any pressure increase during this phase. A significant change indicates the presence of a leak.

- VENT Stage: Release the remaining negative pressure to the atmosphere and evaluate the results. If the sample stays within the specified range, it PASSES; otherwise, it FAILS.

Technical Features

- PLC System Operation: The system is operated via a programmable logic controller (PLC) for enhanced reliability.

- Customizable Chamber Sizes: Tailored sizes are available to accommodate various package dimensions.

- High Sensitivity: The MLT-01 exhibits exceptional sensitivity, capable of detecting minute leaks in the range of 1–3 μm.

- Effective Leak Rate Calculation: The tester accurately calculates the leak rate, providing critical data for quality assurance.

- Efficient Testing Method: The MLT-01 streamlines the testing process, offering a straightforward approach to leak detection.

Applications and Benefits

The MLT-01 Micro Leak Tester is ideal for various industries, including pharmaceuticals, food and beverage, medical devices, and packaging. Its non-destructive testing capabilities ensure that product integrity is maintained throughout the production process. By employing this advanced leak testing equipment, companies can prevent costly recalls, enhance product safety, and comply with regulatory requirements.

Non-destructive leak testing equipment, such as the MLT-01 Micro Leak Tester, is essential for maintaining product quality and ensuring consumer safety. With its alignment to ASTM F2338 standards and its innovative design, the MLT-01 provides manufacturers with a reliable solution for leak detection. Invest in the MLT-01 today to enhance your quality assurance processes and protect your products.

FAQ Section

- What is the typical testing time for the MLT-01 Micro Leak Tester?

- Testing times vary, typically ranging from a few seconds to a few minutes, depending on the package size and leak sensitivity required.

- How sensitive is the MLT-01 in detecting leaks?

- The MLT-01 can detect minute leaks in the range of 1–3 μm, making it highly effective for quality assurance.

- Can the chamber size of the MLT-01 be customized?

- Yes, the MLT-01 offers tailored chamber sizes to accommodate various package dimensions and testing requirements.

- What power supply is required for the MLT-01?

- The MLT-01 operates on an AC power supply of 110–220V at 50Hz.

- How does the vacuum decay method compare to other leak testing methods?

- The vacuum decay method is generally more sensitive and efficient than other methods, making it ideal for detecting leaks in nonporous packages without damaging them.