Introduction

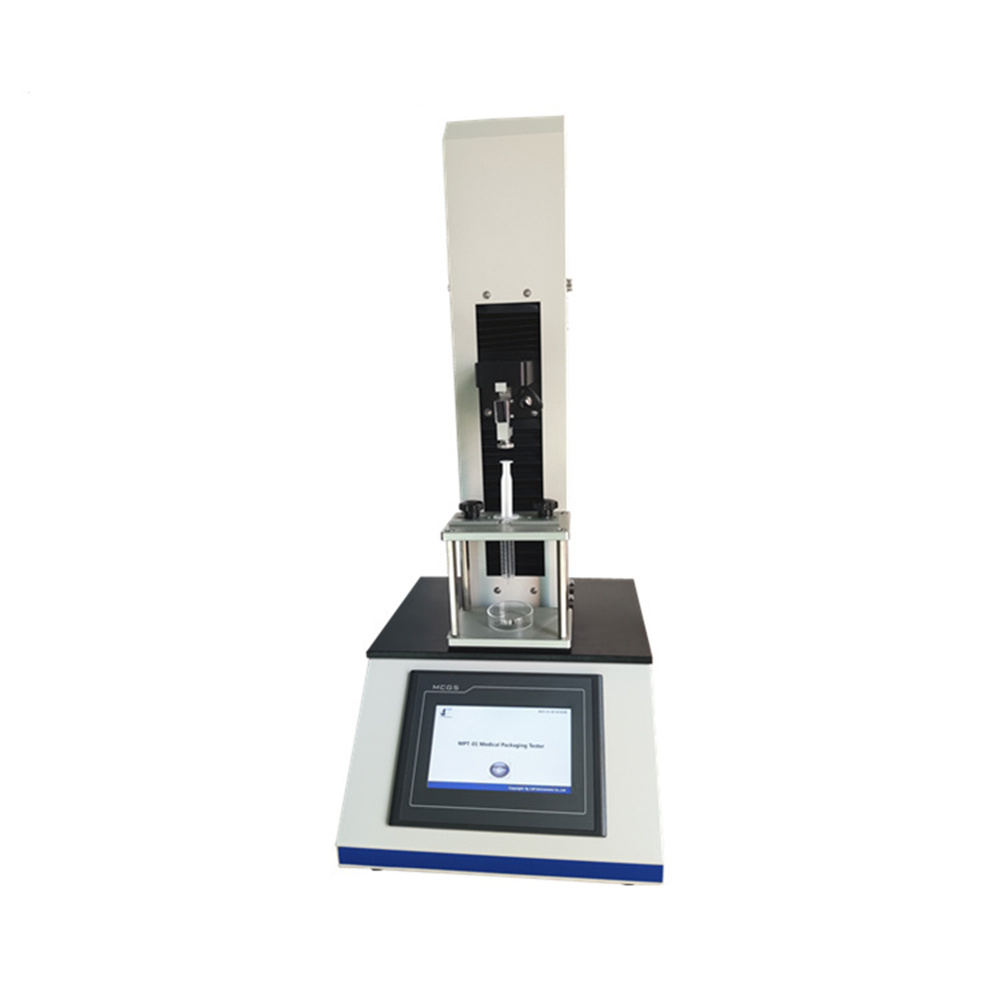

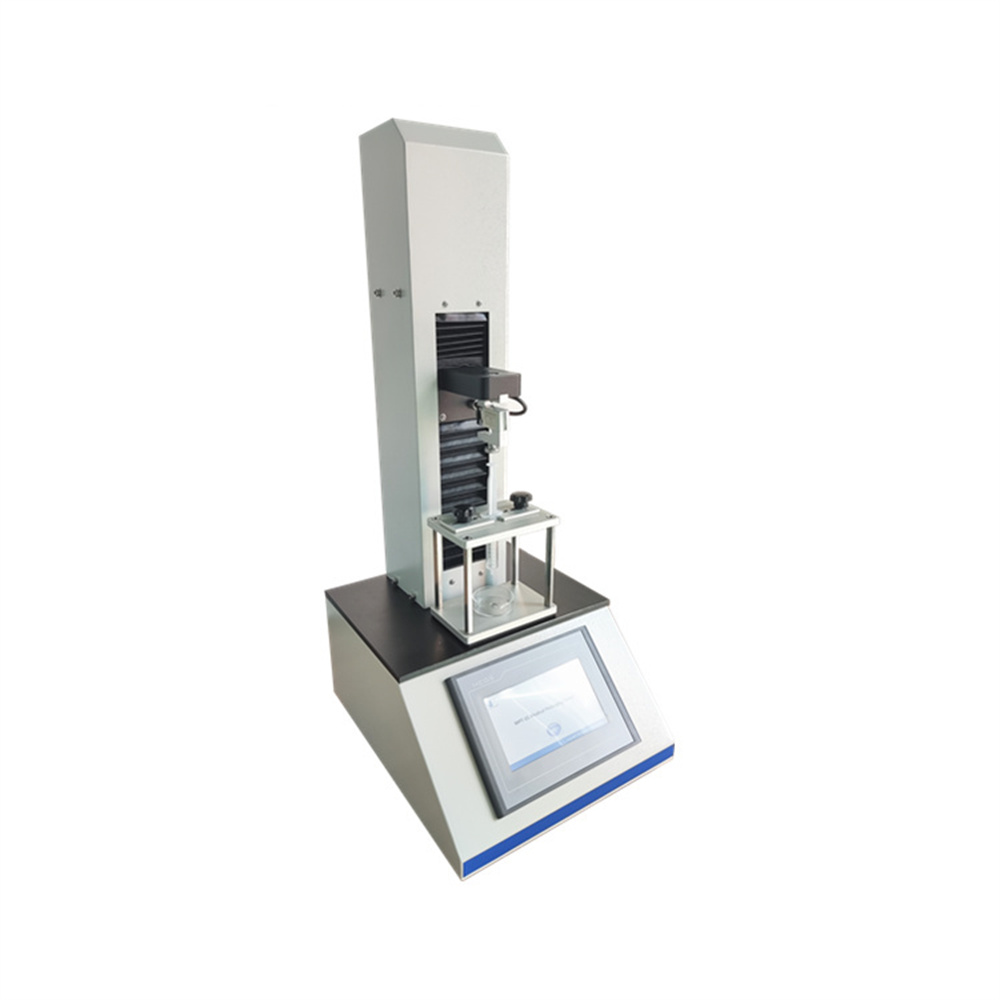

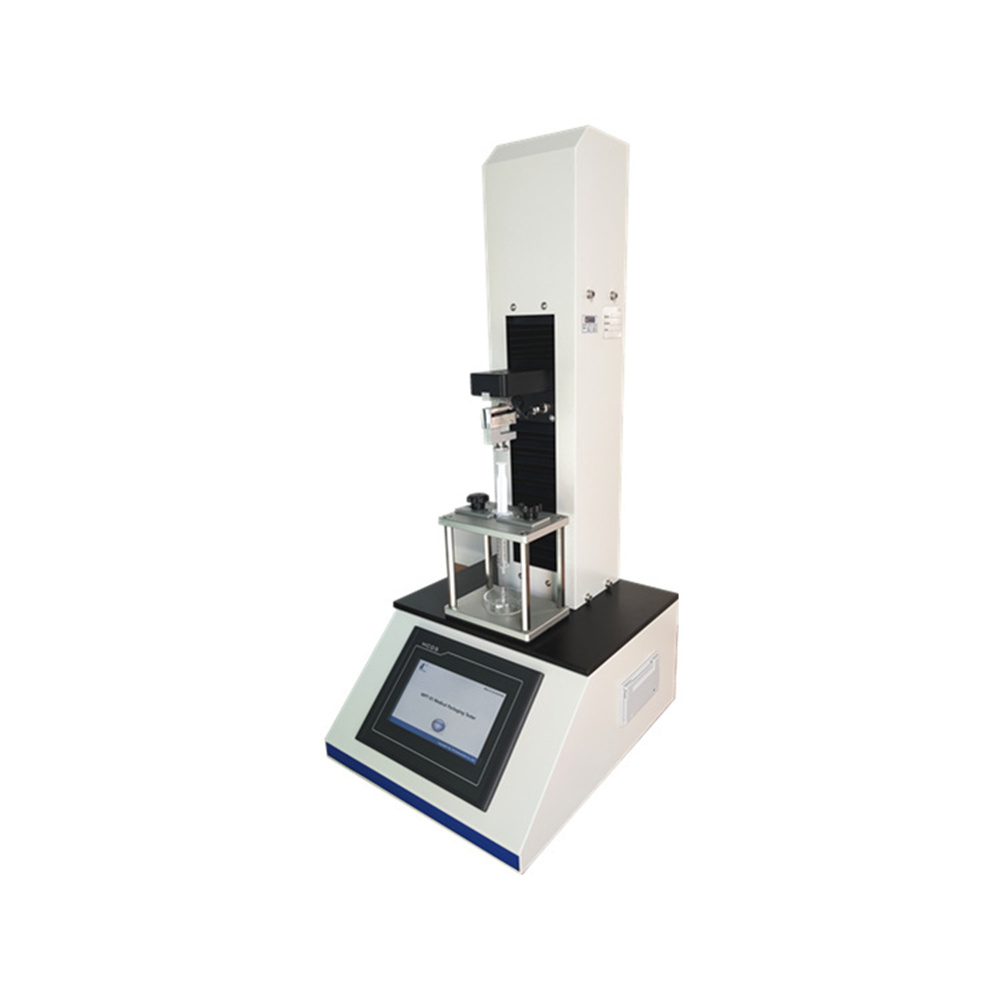

The Medical Device Packaging Testing Machine is an essential tool in the medical and pharmaceutical industries, designed to assess the mechanical properties of packaging materials for medical devices and pharmaceutical products. This machine plays a critical role in ensuring the integrity and safety of packaging, helping manufacturers comply with stringent regulatory standards.

Applications

This versatile machine is capable of testing a wide range of materials commonly used in medical packaging, including polymers, bags, ampoules, rubber stoppers, syringes, and needles. By evaluating these materials, the Medical Device Packaging Testing Machine helps guarantee that packaging can withstand various conditions during transportation and storage.

Test Methods

The Medical Device Packaging Testing Machine performs several crucial tests to ensure the quality of packaging materials:

- Tensile Tests: Measure the force required to pull materials apart.

- Compression Tests: Assess the ability of packaging to withstand external pressure.

- Tear Tests: Evaluate the resistance of materials to tearing.

- Opening Force Tests: Determine the force needed to open sealed packaging.

- Penetration Tests: Test the integrity of rubber stoppers and seals.

- Breaking Strength Tests: Assess the maximum load a material can bear before failing.

- Pull Tests: Measure the strength of connections in packaging components.

Versatility

This machine supports various tests essential for quality assurance in medical packaging. Key tests include:

- Penetration Test of Rubber Stoppers in antibiotic bottles and hypodermic needles: Ensures that stoppers maintain their integrity when penetrated.

- Fracture Strength Test of ampoule bottles: Tests the resistance of bottles to breakage.

- Leak Test of plastic packages under external pressure: Verifies the sealing integrity of packaging.

- Connection Force Test between hypodermic needles and needle hubs/caps: Assesses the reliability of these connections.

- Bottle Stiffness Test: Measures the rigidity of bottles to prevent deformation.

- Bottle Lid Puncture Test with animated finger: Evaluates the puncture resistance of lids.

- Sliding Resistance Test of pistons: Tests the performance of moving components in medical devices.

Technical Features

The Medical Device Packaging Testing Machine is equipped with advanced technical features to enhance its performance:

- Programmable Logic Controller (PLC): Provides stable and reliable control.

- Human-Machine Interface (HMI) Touch Screen: Ensures user-friendly operation.

- Precision Ball Lead Screw Mechanism: Guarantees accurate and consistent speed and displacement control.

- Customizable Programs: Designed to cater to specific testing requirements.

- Adjustable Test Speed: Allows flexibility in testing conditions.

- Multiple Fixtures: Available for pulling and compression tests, tailored to specific materials.

- Safety Features: Include limit protection and automatic returning for safe operation.

Main Parameters

| Test Range | 500N (or as required) |

| Stroke | 200mm (without clamp) |

| Test Speed | 1~500mm/min |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Control | PLC and human machine interface |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~220V |