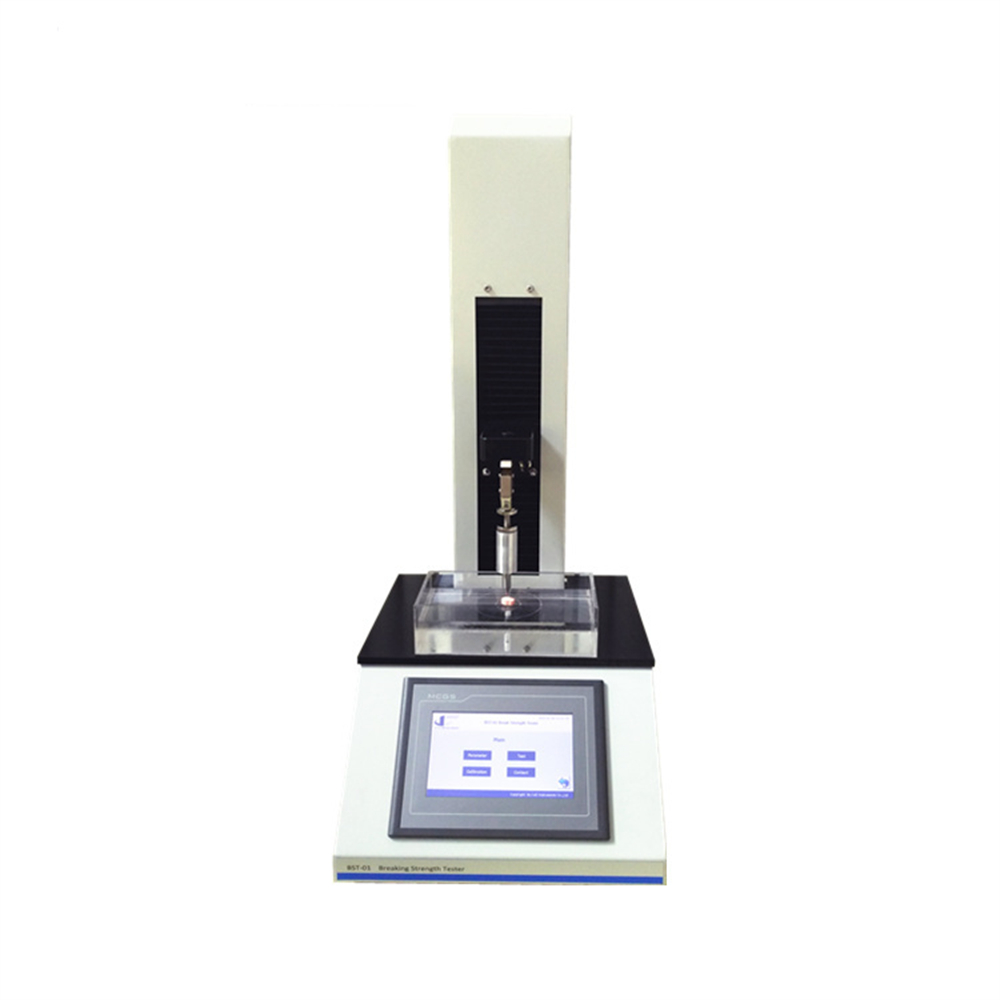

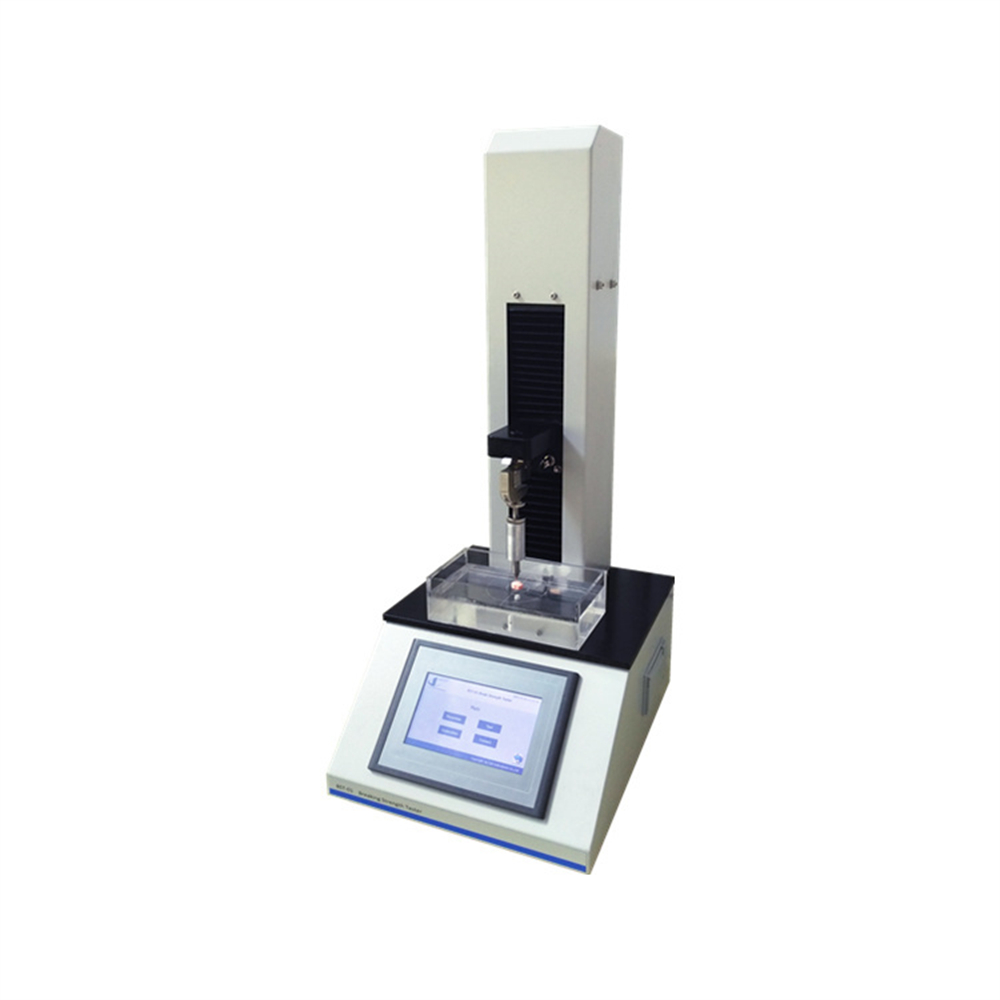

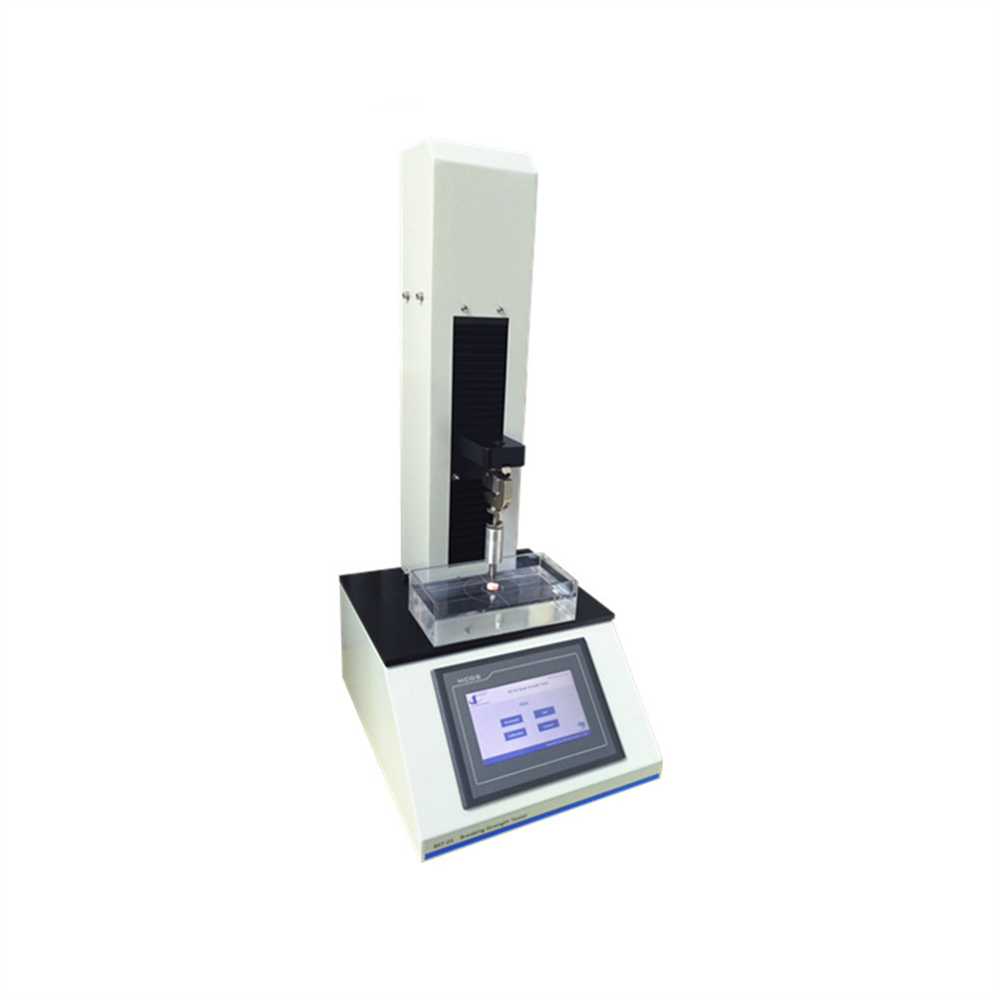

The Hardness Test Apparatus for Tablet is an advanced instrument designed for precise and reliable tablet hardness testing, an essential process in the pharmaceutical industry. By assessing the compressive strength of tablets, this apparatus ensures that tablets maintain their physical integrity during production, storage, and use, ultimately safeguarding drug efficacy and patient safety. Pharmaceutical manufacturers rely on tablet hardness testing not only to meet stringent regulatory standards but also to enhance product quality and competitiveness in the market.

Importance of Tablet Hardness Test in Pharmaceutical Production

Tablet hardness testing plays a crucial role in ensuring the overall quality and safety of pharmaceutical tablets. Testing tablet hardness helps to:

- Ensure Tablet Quality: Tablets with low hardness may fracture during transport or handling, while excessive hardness can impede tablet disintegration, negatively affecting drug release and bioavailability. An optimal hardness range ensures that tablets withstand handling without compromising therapeutic effectiveness.

- Optimize Production Processes: Routine hardness testing helps identify inconsistencies in production, such as improper compression force or formulation issues, allowing manufacturers to adjust processes promptly and improve tablet uniformity.

- Guide Product Design: Hardness data assists in designing new formulations that meet specific hardness and disintegration requirements, crucial for developing effective, safe, and user-friendly tablets.

Principles of Tablet Hardness Testing

Tablet hardness testing involves placing the tablet on the measurement platform of the hardness tester, where a controlled force is applied through an upper punch. The tester measures either the deformation of the tablet or the force required to fracture it, providing insight into its hardness. Key measurement methods include:

- Indentation Depth Method: This method gauges hardness by recording the depth of an indentation formed under a set pressure. Shallower indentations indicate a harder tablet, making this method effective for consistency checks.

- Crushing Strength Method: This approach measures the force needed to crush the tablet. A greater force implies a harder tablet, offering critical data for quality control and compliance.

Key Features of the Hardness Test Apparatus

This hardness test apparatus is engineered with advanced features to ensure precision, durability, and ease of use in pharmaceutical environments:

- User-Friendly Interface: Equipped with a 7-inch HMI touchscreen for intuitive operation and easy navigation.

- Industrial-Grade Stability: Built with a high-performance PLC control unit for reliable and consistent testing results.

- High-Precision Components:

- Loadcell: Delivers accurate force measurements, crucial for regulatory compliance and quality assurance.

- Ball Screw System: Provides precision force application, minimizing variability in test results.

- Adjustable Test Speed: Allows operators to modify test speeds based on specific testing requirements, enhancing versatility in various testing scenarios.

- Real-Time Data Display: Displays force data in real-time during testing, providing immediate feedback and tracking for efficient quality control.

- Easy Calibration: A simplified calibration process saves time and ensures accuracy in line with industry standards.

- Versatile Testing Capabilities: Comes with multiple fixtures to accommodate different testing configurations, making the apparatus adaptable to diverse tablet sizes and formulations.

- Additional Functionalities:

- Includes a position restrictor and automatic return function for efficient handling.

- Optional microprinter output and software integration for data management and traceability.

Main Parameters of the Tablet Hardness Tester

This apparatus is engineered to meet high standards in pharmaceutical testing. Key specifications include:

- Load Range: Wide range to accommodate various tablet hardness levels.

- Accuracy and Resolution: High precision for consistent and reproducible results.

- Test Speed Range: Adjustable test speeds to meet specific testing needs.

- Dimensions: Compact design suited for lab or production environments.

Applications of the Tablet Hardness Test Apparatus in Industry

The hardness test apparatus for tablet has broad applications across pharmaceutical production and research settings:

- Pharmaceutical Production: Ensures tablet quality, uniformity, and regulatory compliance during mass production.

- Research & Development: Provides essential data for developing and refining drug formulations, supporting the creation of effective and safe medication.

- Quality Control: Routine hardness testing in production lines and quality inspection ensures consistency and reliability in pharmaceutical products, meeting both regulatory standards and patient needs.

Benefits of Using the Hardness Test Apparatus for Tablet Quality Control

With advanced features and flexible functionality, this hardness test apparatus for tablet offers numerous benefits to manufacturers:

- Enhanced Product Consistency: Achieves reliable quality control, improving the overall quality of pharmaceutical tablets.

- Streamlined Data Management: Real-time results and optional data output enable easy tracking, enhancing efficiency and traceability.

- Regulatory Compliance: Simplifies adherence to stringent quality standards, ensuring tablets meet required specifications for market release.