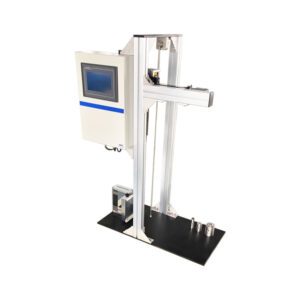

Introduction to the GHR-01A Glass Grains Sampler For Hydrolytic Resistance

The GHR-01A Glass Grains Sampler For Hydrolytic Resistance is an advanced instrument designed to assess the chemical stability of glass materials against water. This crucial quality control test is vital in the pharmaceutical industry, as it determines how packaging materials, such as glass bottles and ampoules, interact with the medications they contain, directly impacting the stability and safety of these products.

Understanding Hydrolytic Resistance Testing

Hydrolytic resistance testing evaluates the tendency of glass materials to degrade when in contact with water. This degradation can release ions that may compromise the efficacy of pharmaceuticals. Ensuring that glass packaging exhibits high hydrolytic resistance is essential for maintaining the integrity of medicinal products and preventing adverse reactions.

Standards for Hydrolytic Resistance Testing

- ISO 719: Glass – Hydrolytic resistance of glass grains at 98℃

This standard outlines the test method and classification for assessing the hydrolytic resistance of glass grains at a temperature of 98℃. It provides guidelines on how to prepare samples and evaluate their resistance to water, which is crucial for ensuring that glass packaging maintains its integrity under typical storage conditions. - ISO 720: Glass – Hydrolytic resistance of glass grains at 121℃

Similar to ISO 719, this standard focuses on testing glass grains at an elevated temperature of 121℃. It offers a rigorous methodology for evaluating how glass materials perform under more extreme conditions, which is particularly relevant for sterilization processes.

Test Methodology

The testing process involves placing the glass sample into a mortar, where an automated pestle descends to crush the glass into fragments. The device then vibrates a series of sieves, separating qualified samples from the glass granule waste. This automated approach ensures that samples are prepared accurately and efficiently, adhering to the standards set forth by ISO 719 and ISO 720.

Features and Benefits of the GHR-01A Tester

- Smart Automation: The GHR-01A combines crushing and vibration sieving into a single unit, facilitating seamless sample preparation and ensuring standard-compliant sample sizes.

- User-Friendly Interface: The HMI screen operations provide straightforward human-machine interaction, making it easy for operators to manage the testing process.

- Safety Features: Reduced manual handling enhances safety for personnel, while built-in safety devices protect against glass splatters, maintaining the integrity of the test.

- Eco-Friendly Design: The device includes specialized glass waste collection to minimize environmental impact.

- Precision Testing: Automated sieving improves accuracy, allowing for reliable results.

- Limit Switch Function: Added safety measures prevent operational hazards.

- Optimized Design: The vertical layout reduces gravitational effects on larger samples, ensuring consistent test results.

Main Parameters

| Mortar/Pestle Dimension | Φ50/Φ48 mm |

| Sieve A Aperture | 425μm |

| Sieve B Aperture | 300μm |

| Sieve O Aperture | 600μmμm |

| Sieve Shaking Duration | 5min |

| Gas Pressure | 0.5 Mpa |

| Gas Port Size | Ф6 mm |

| Power | AC 110~220V 50Hz |

Applications of the GHR-01A Tester

The GHR-01A is essential for a wide range of applications, particularly in the pharmaceutical and medical device industries. It is ideal for preparing hydrolytic resistance samples of glass granules used in various medical glass products, including infusion bottles, injection bottles, ampoules, and oral liquid bottles.

In summary, the GHR-01A Glass Grain Hydrolytic Resistance Tester is a sophisticated solution for ensuring the quality and safety of medicinal glass packaging. By adhering to ISO standards, this instrument provides reliable results that are crucial for maintaining the integrity of pharmaceutical products. Choose the GHR-01A for your testing needs to ensure the highest standards of quality control.

FAQs

- What is hydrolytic resistance? Hydrolytic resistance refers to the ability of glass materials to resist degradation when exposed to water, crucial for maintaining pharmaceutical stability.

- How does the GHR-01A Tester work? The tester automatically crushes glass samples and vibrates sieves to separate compliant granules from waste, streamlining the testing process.

- What standards does the GHR-01A comply with? The GHR-01A complies with ISO 719 and ISO 720 standards for hydrolytic resistance testing of glass grains.

- What types of products can be tested? The GHR-01A is suitable for testing glass used in infusion bottles, injection bottles, ampoules, and oral liquid containers.

- Is the testing process safe? Yes, the GHR-01A is designed with multiple safety features to protect personnel and maintain test integrity.