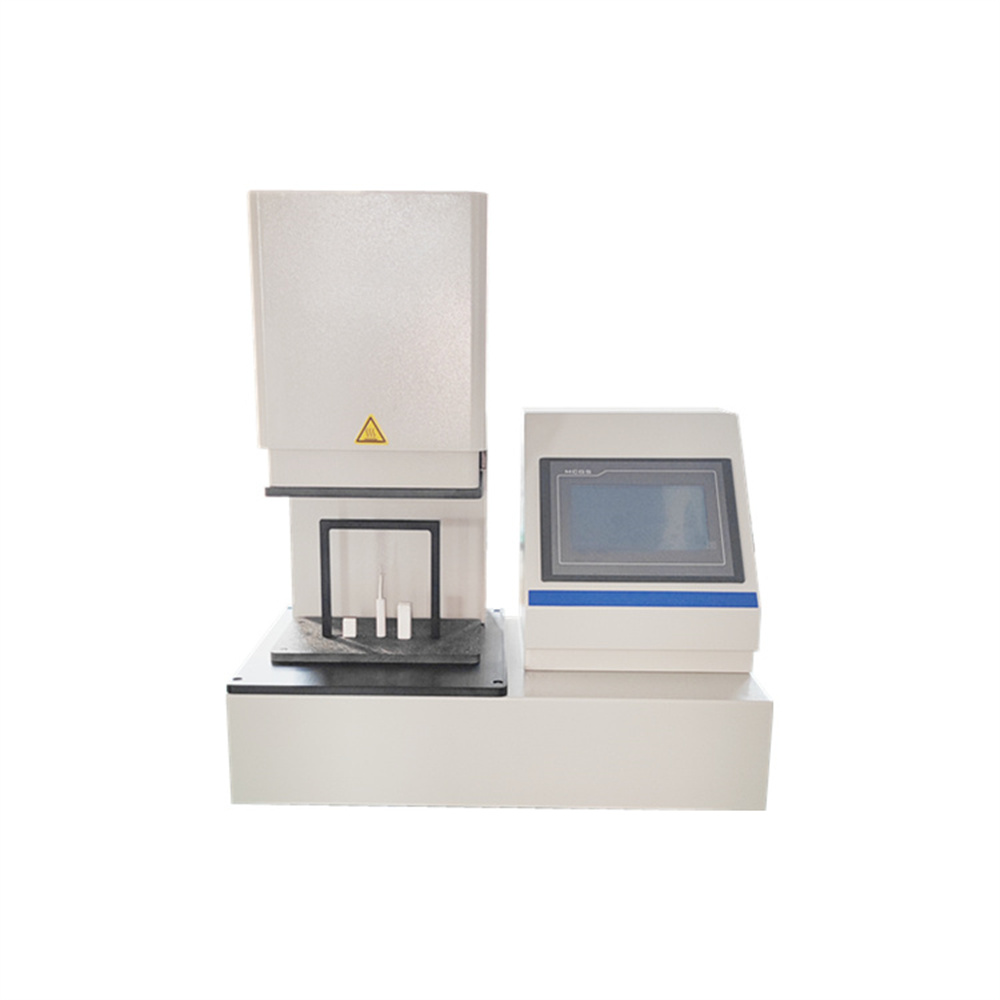

FSR-01 Film Shrinkage Tester

The Film Shrinkage Tester is a crucial tool for ensuring the quality and reliability of heat shrinkable films in various applications. By providing accurate measurements of shrink forces and ratios, it aids manufacturers in maintaining high standards and optimizing their processes. For those interested in enhancing their quality control measures, we encourage you to explore further or request a demonstration to see the capabilities of this essential instrument in action.

Introduction of Film Shrinkage Tester

The Film Shrinkage Tester is an essential instrument designed to measure the shrink forces and shrinkage ratios of heat shrinkable films. These films are commonly used in various industries, including packaging, food, medical, and pharmaceuticals. Manufactured through extrusion and stretching (hot drawing), these films maintain a stretched state until reheated. When exposed to the specific temperatures that release the initial stress, the films contract, or “shrink back,” making accurate measurement critical for quality assurance.

Test Methods

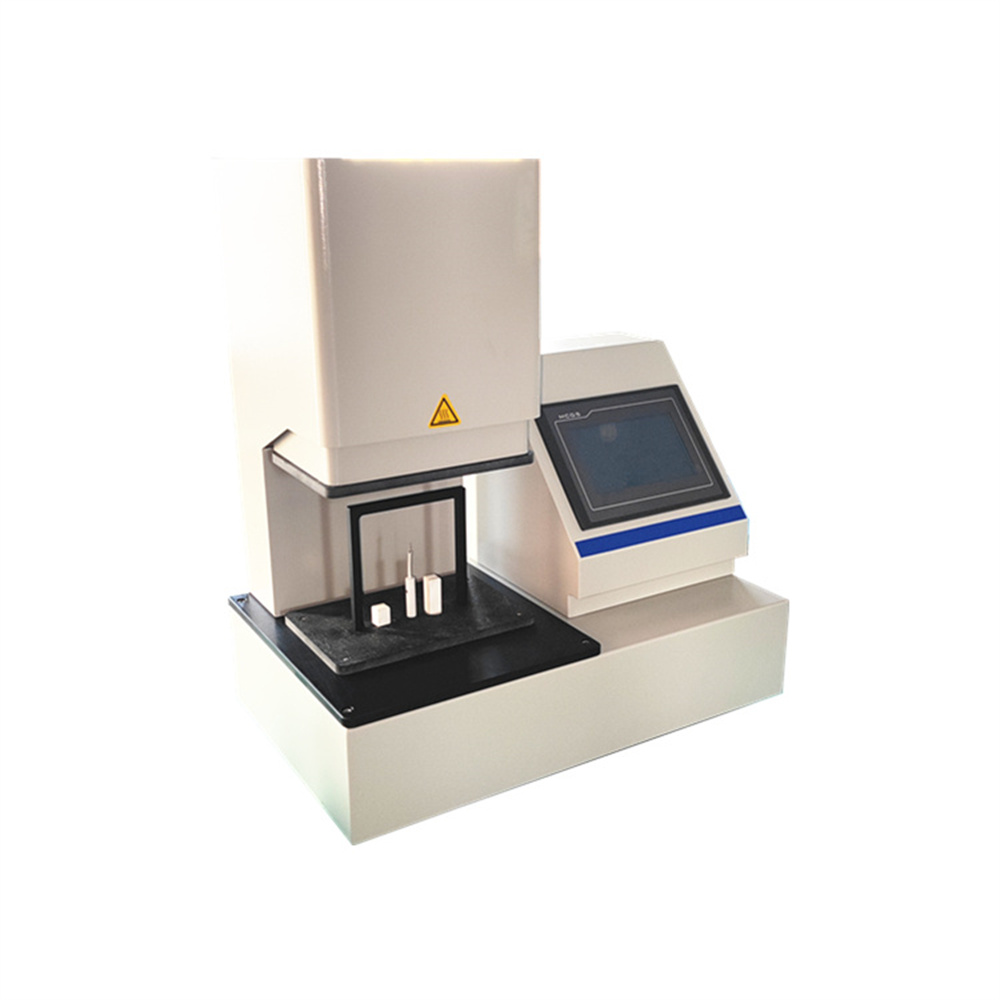

Test Process

- Preparation: The testing begins with a well-insulated air oven, which is heated to a predetermined temperature. Two samples are placed separately on designated test stations for assessing shrinkage rate and shrink/contraction force.

- Measurement Setup: A temperature probe is positioned to monitor the sample area, providing precise temperature readings. The air oven automatically lowers to cover the sample area, facilitating accurate testing.

- Data Collection: As the temperature rises, the maximum shrink force is measured, indicating when the shrinkage temperature has been reached. The process records the moment when this force decreases by approximately 15% to 30%, lifting the air oven and noting the time elapsed.

- Shrinkage Ratio Assessment: During the testing phase, the shrinkage ratio is evaluated, offering vital insights into the film’s performance characteristics.

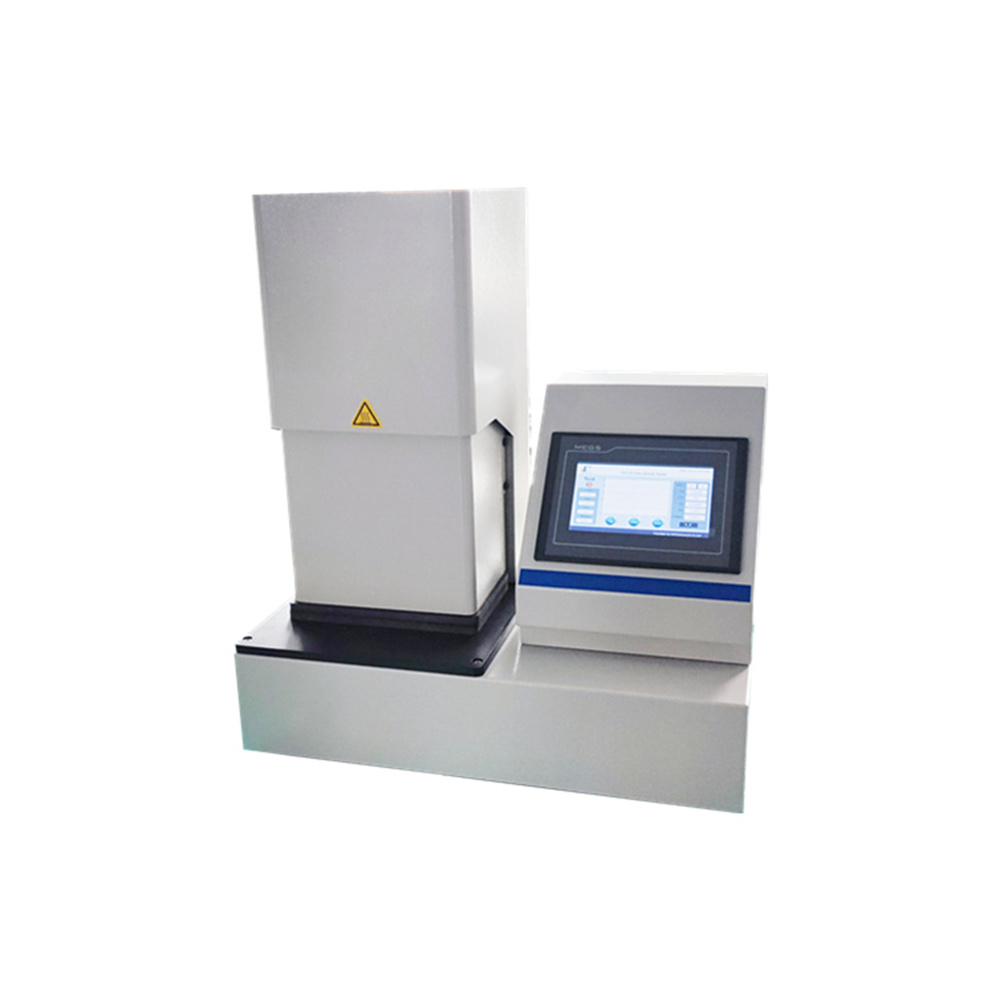

Technical Features

- PLC Control and HMI Touch Screen: This feature ensures industrial-level stability while providing a user-friendly interface for easy operation.

- Well-Insulated Air Oven: The air oven is expertly insulated and capable of automatic lowering and lifting, which enhances testing precision.

- Non-Contact Shrink Ratio Measurement: Achieved through a non-contact method, this functionality significantly improves the accuracy and reliability of results.

- Real-Time Display: The tester provides a real-time display of key metrics, including shrinking force, contracting force, and shrinkage ratio, allowing for immediate analysis.

- Elimination of Interference Factors: By effectively eliminating irrelevant interference factors such as friction and cool air, the system ensures the accuracy of test results.

- Stable Heating System: A stable and well-balanced heating system maintains consistent test conditions, essential for reliable measurements.

- Easy Sample Loading: The design simplifies sample loading, streamlining the testing process and reducing setup time.

- High-Resolution Sensors: Equipped with high-resolution force transducers and thermometers, the system guarantees precise measurements throughout the testing process.

- Connectivity and Software Options: The Film Shrinkage Tester includes an RS232 port for data connectivity and offers optional professional software for advanced data analysis and reporting capabilities.

Standards

The Film Shrinkage Tester complies with key industry standards to ensure reliable performance:

- ISO 14616: This standard focuses on the testing methods applicable to shrinkable films, providing a framework for accurate measurement.

- DIN 53369: Addresses the material testing standards relevant to heat shrinkable films, ensuring compliance with industry practices.

Main Parameters

| Force Range | 5 N ( or as required) |

| Accuracy | ±0.5% |

| Resolution | 0.001N |

| Displacement Range | 0.1 ~ 95 mm |

| Accuracy | ±0.1 mm |

| Temperature Range | Ambient ~ 210°C |

| Accuracy | ±0.5°C |

| No. of Specimens | 2 |

| Sample size | 110*15 mm, L*W |

| Power Supply | 220V 50Hz |

The Film Shrinkage Tester is a crucial tool for ensuring the quality and reliability of heat-shrinkable films in various applications. By providing accurate measurements of shrink forces and ratios, it aids manufacturers in maintaining high standards and optimizing their processes. For those interested in enhancing their quality control measures, we encourage you to explore further or request a demonstration to see the capabilities of this essential instrument in action.