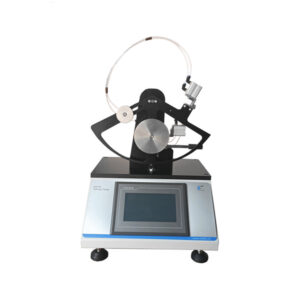

Impact resistance is a vital characteristic for materials exposed to sudden or continuous impacts. The Drop Weight Impact Tester provides an accurate, reliable method to assess the durability of various materials, including films, foils, paper, plastic sheets, and composites under 2mm thickness. This tester plays a crucial role in quality control and product development across industries, ensuring materials meet stringent standards for performance and durability.

Compliant with ASTM D1709 and ISO 7765-1 Standards

The Drop Weight Impact Tester is designed to meet the requirements of ASTM D1709 and ISO 7765-1—two of the most widely recognized standards for impact resistance testing. ASTM D1709 focuses on the impact resistance of plastic films using a free-falling dart method, ensuring materials withstand puncture forces effectively. ISO 7765-1 provides a standard test method for determining the impact strength of thermoplastic films, making this tester ideal for both regional and international testing compliance. Meeting these standards guarantees that this tester produces highly reliable, standardized results suitable for a wide array of applications.

Applications of the Drop Weight Impact Tester

The tester serves numerous sectors, including packaging, pharmaceuticals, food and beverage, electronics, and daily chemicals. It assesses the resistance of materials like packaging films, plastic wraps, and protective foils, which often endure impact forces in handling, transportation, and consumer use. By evaluating the impact resistance of materials, this tester helps manufacturers ensure that their products maintain structural integrity, protecting contents and meeting industry standards.

Test Method for Drop Weight Impact Testing

The Drop Weight Impact Tester uses a steel ball or dart of specified mass and diameter, which is dropped from a predetermined height to simulate a controlled impact force on the material. The tester measures the resulting damage, deformation, and energy absorbed by the material, providing a quantifiable analysis of its impact resistance. Key factors influencing test results include:

- Drop Height: Adjustable from 300mm to 600mm (and extendable as needed), simulating different impact conditions for customized testing scenarios.

- Ball Size and Mass: Configurable based on the testing standard and application requirements, allowing accurate simulation of real-world impacts.

Key Features of the Drop Weight Impact Tester

- Adjustable Impact Height: Customize the impact height for different testing scenarios, allowing accurate and flexible impact testing.

- Electromagnetic Suspension System: This feature ensures a consistent release mechanism, minimizing variability and enhancing accuracy.

- Pneumatic Sample Clamping: The pneumatic clamping mechanism securely holds the test specimen, preventing movement that could compromise results.

- User-Friendly Operation: The tester is equipped with foot switches, allowing easy operation and facilitating hands-free control for safe, effective testing.

Technical Specifications

| Impact Height | 300mm-600mm (can be extended) |

| Ball Diameters (mm) | 23, 25, 28.6, 38.1, 50.8(one equipped) |

| Accuracy | 0.1g (0.1J) |

| Specimen Clamp | Pneumatic Clamp |

| Gas Supply | 0.6 MPa Φ8 mm PU Tubing |

| Specimen Size | > 150 mm x 150 mm |

| Power Supply | AC 110~220V 50Hz |

Advantages of the Drop Weight Impact Tester

Using this tester provides consistent and accurate results that inform quality control measures and material selection in manufacturing. By ensuring compliance with ASTM D1709 and ISO 7765-1, this impact tester helps industries meet regulatory standards and customer expectations for durability and safety, particularly in packaging and materials manufacturing. The tester is also an ideal choice for research and development environments, where reliable impact resistance data guides new product development.

Compliance with ASTM D1709 and ISO 7765-1 Standards

The Drop Weight Impact Tester is fully compliant with ASTM D1709 and ISO 7765-1, which means it is certified for standardized testing and applicable to both local and international markets. This ensures that users can rely on accurate and comparable results across various testing facilities and production lines, simplifying quality control and regulatory compliance.

Frequently Asked Questions (FAQs)

- What types of materials can be tested with a drop weight impact tester?

- This tester is suitable for films, foils, paper, plastic sheets, and other thin materials up to 2mm thick.

- Why are ASTM D1709 and ISO 7765-1 important for impact testing?

- These standards specify consistent methods for testing impact resistance, ensuring reliable, comparable results across industries.

- What factors can influence the accuracy of the impact test?

- Key factors include drop height, ball size, and specimen clamping, all of which can be controlled to meet specific testing needs.

- How does the electromagnetic suspension system improve testing accuracy?

- The electromagnetic suspension ensures a precise, consistent drop, reducing variations and improving result accuracy.

- What industries benefit most from using a drop weight impact tester?

- Industries such as packaging, pharmaceuticals, electronics, and food and beverage production benefit from verifying material durability against impact forces.