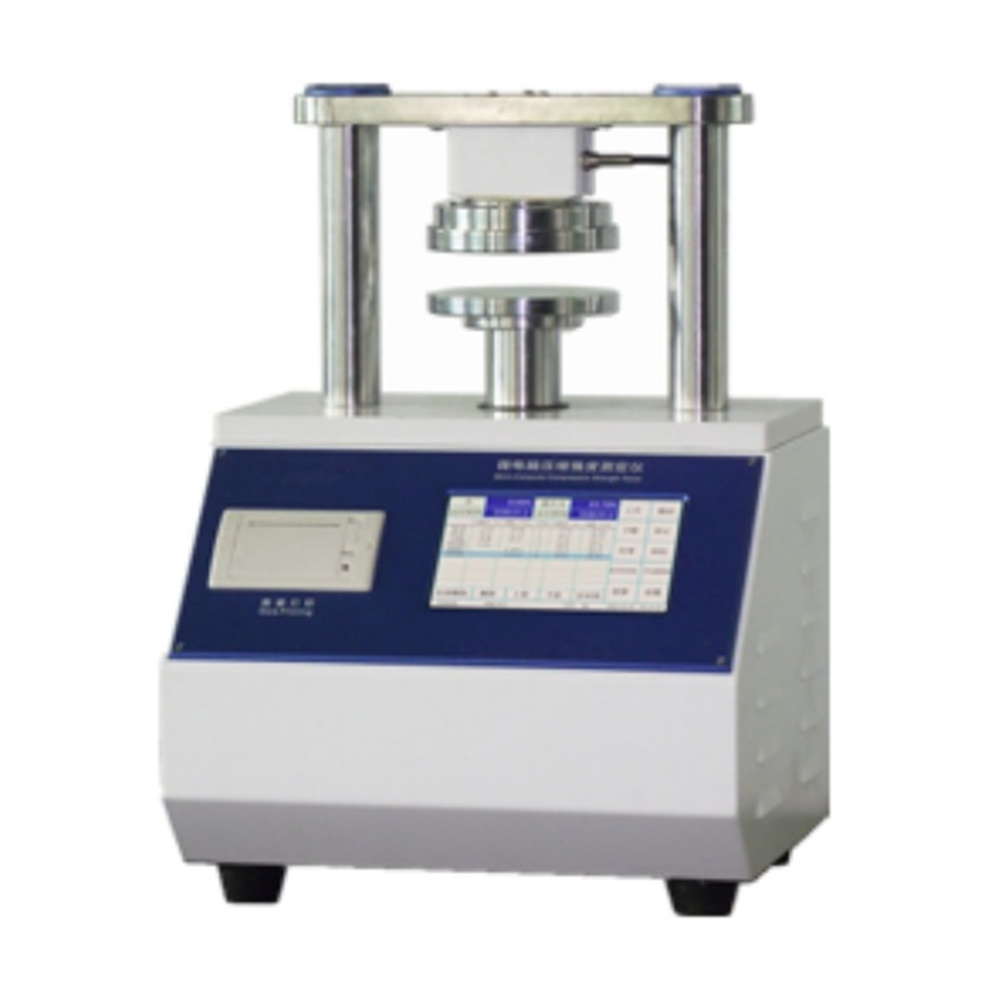

Overview of the Crush Resistance Tester

The Crush Resistance Tester (YSD-01) is a high-precision testing instrument designed to evaluate the crush resistance of packaging materials, particularly fiberboard and corrugated paper. This tester is essential for industries that rely on durable and resilient packaging to safeguard products during storage and transportation. By accurately measuring the in-plane compressive forces that materials can withstand, the YSD-01 ensures that packaging meets required performance standards, reducing the risk of product damage in transit.

Key Applications of the Crush Resistance Tester

- Packaging and Shipping Industry: This tester is invaluable in evaluating fiberboard and corrugated containers used across the packaging sector. By assessing the crush resistance of these materials, manufacturers can optimize packaging design to withstand various compressive forces encountered during handling, stacking, and shipping.

- Industries Benefiting from Crush Resistance Testing: The Crush Resistance Tester supports quality control across multiple industries, including food and beverage, pharmaceuticals, electronics, daily chemicals, and more. By helping ensure packaging durability, it aids in preserving product integrity from production to end use.

Understanding Crush Resistance Test Types and Methods

The YSD-01 is versatile and equipped to perform a range of crush resistance tests. Each test evaluates specific characteristics of packaging materials to ensure they meet the rigorous demands of the industry.

- Edgewise Crush Test (ECT): This test evaluates the edgewise compressive strength perpendicular to the axis of the flutes in fiberboard. ECT is a critical measure for assessing the stacking strength of corrugated packaging materials.

- Ring Crush Test (RCT): The RCT determines the edgewise compressive strength, or ring crush resistance, of paper and paperboard. This test provides insight into the material’s structural integrity and resistance to crushing forces.

- Pin Adhesion Test (PAT): Used to measure the force needed to separate the corrugated board between flute tips and linerboard facings, PAT is crucial for ensuring the bonding strength within corrugated board layers.

- Flat Crush Test (FCT): This test measures the flat crush resistance of single-faced and single-wall corrugated fiberboard. FCT is essential for understanding how well the material can resist compressive forces applied on its surface.

- Corrugating Medium Test (CMT): The CMT test evaluates the flat crush resistance of the corrugating medium after laboratory fluting, helping ensure the medium’s durability in real-world applications.

- Concora Crush Test (CCT): This test measures the maximum edgewise compression force that a laboratory-fluted test piece can withstand before failure, critical for assessing the load-bearing strength of the corrugating medium.

Relevant Standards for Crush Resistance Testing

The Crush Resistance Tester adheres to several industry standards, which ensure consistent, accurate, and reliable testing results:

- RCT Standards: GB/T 2679.8, ISO 12192, TAPPI T822 – These standards establish protocols for measuring ring crush resistance.

- ECT Standards: GB/T 6546, ISO 3037, TAPPI T811, T838, T839 – Ensures the accuracy of edgewise crush resistance testing for packaging applications.

- PAT Standards: GB/T 6548, TAPPI T821, JIS Z 0402 – Defines test methods for measuring adhesion between flute tips and linerboard in corrugated materials.

- FCT Standards: GB/T 22874, ISO 3035, TAPPI T825 – Governs procedures for flat crush resistance testing of corrugated fiberboard.

- CMT Standards: ISO 7263-1, TAPPI T809, QB/T 1061, GB 2679.6 – Provides standardized guidelines for evaluating flat crush resistance of corrugating medium.

- CCT Standards: ISO 16945, TAPPI T843 – Sets the benchmark for assessing the edgewise compression force in laboratory-fluted test pieces.

These standards support quality assurance by validating the tester’s performance across various crush resistance measurements, ensuring materials meet high industry standards for durability and strength.

Technical Specifications of the Crush Resistance Tester (YSD-01)

| Test Range | 5~3000N |

| Accuracy | ≤±1% |

| Resolution | 0.01N |

| Platen Parallelism | ≤0.05mm |

| Test Speed | 12.5±1mm/min |

| Platen Diameter | 125mm |

| Stroke | 80mm |

| Test Mode | RCT, ECT, FCT, PAT, CMT, CCT |

| HMI | 7in Touch Screen Display |

| Print Output | Integrated Thermal Printer |

| Dimensions | 400*360*550mm |

| Weight | About 45kg |

Advantages of the Crush Resistance Tester

- Precision and Reliability: Engineered for accuracy, the YSD-01 offers precise measurement with minimal error, making it ideal for exacting quality control environments.

- Versatility Across Testing Methods: With capabilities for various crush tests, the tester allows companies to conduct comprehensive assessments of material strength and performance within a single unit.

- User-Friendly Operation: The 7-inch touch screen and built-in thermal printer simplify testing processes, allowing users to quickly set up, execute, and document results.

The Crush Resistance Tester (YSD-01) is an essential instrument for industries focused on maintaining high packaging quality standards. Its versatile testing capabilities, adherence to industry standards, and high-precision results make it a valuable tool for companies that need to ensure product safety and packaging integrity across the supply chain.