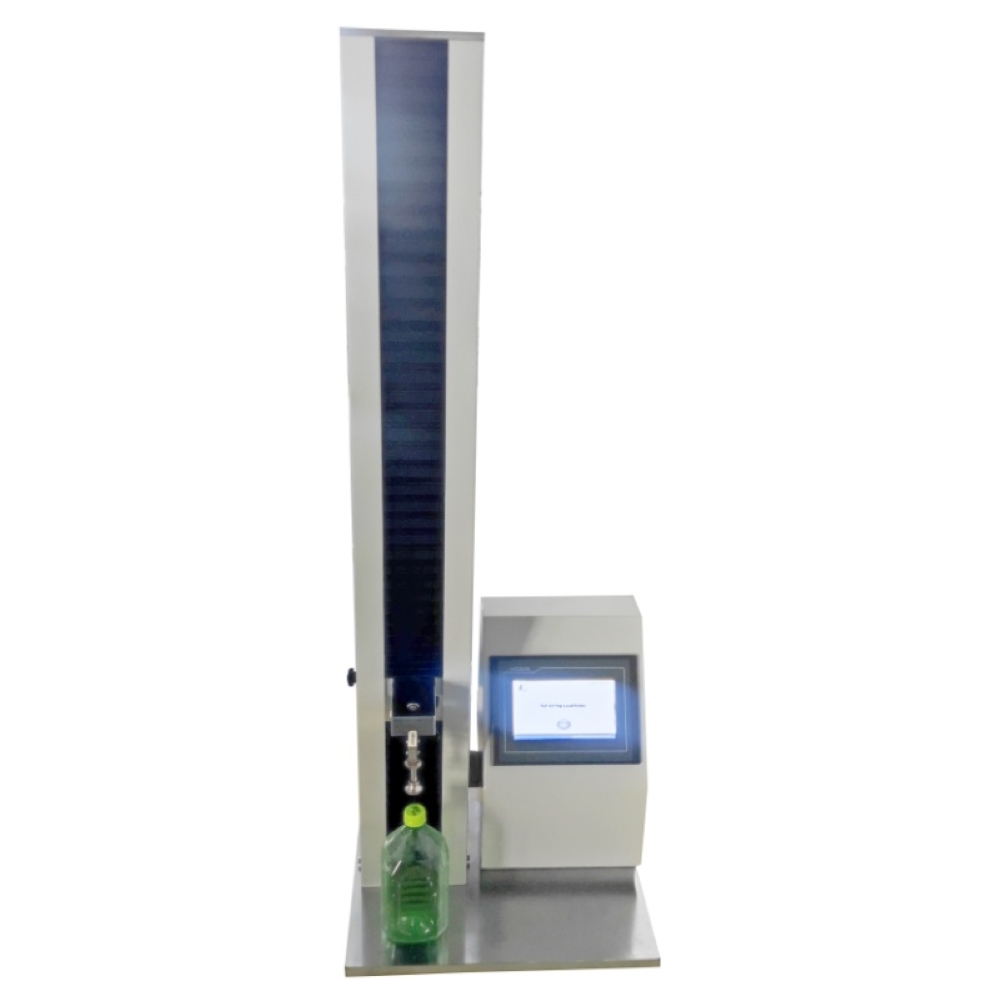

The Container Top Load Testing Machine is an advanced solution designed to assess the structural integrity and compressive strength of various packaging containers. By accurately measuring the load-bearing capacity of containers like bottles, jars, cartons, and boxes, this machine helps manufacturers ensure their products withstand stacking, shipping, and storage stresses without deformation or collapse. With this machine, Cell Instruments offers a top-tier solution for industries such as food, pharmaceuticals, and consumer goods, where packaging durability is paramount to product safety and quality.

Importance of Top Load Testing in Packaging

In modern packaging, ensuring container strength and reliability is essential. Top load testing verifies that containers can endure compressive forces encountered during stacking and transportation, protecting the product inside and preventing costly damages, returns, and replacements. Additionally, this testing aids manufacturers in optimizing packaging design and material usage, promoting cost-effectiveness and sustainability while maintaining quality and brand reputation.

ASTM D2659 Standard

ASTM D2659 is a key standard for evaluating the compressive strength of rigid plastic containers. It provides standardized methods for assessing how well these containers withstand top-down loads, an essential measure for ensuring structural integrity and performance.

- ASTM D2659 Testing Methods: Following ASTM D2659 guidelines, the top load test applies a controlled compressive force to the container’s top, incrementally increasing until deformation or failure occurs. This method offers critical data on maximum load tolerance, helping ensure that containers meet industry safety and performance standards.

- Compliance Benefits: Adherence to ASTM D2659 boosts reliability and regulatory compliance, giving manufacturers and consumers confidence in the durability of the packaging.

Key Technical Features of the Container Top Load Testing Machine

Engineered for accuracy, convenience, and adaptability, the Container Top Load Testing Machine is equipped with advanced features to meet varied testing requirements.

- Advanced Control and Display:

- The machine features a 7-inch HMI touch screen for seamless user interaction and operational ease.

- It operates under a PLC control system, which offers industrial-grade stability and efficiency.

- Precision and Flexibility:

- With a precision ball lead screw, the machine achieves exact control over speed and displacement, providing reliable and repeatable results.

- The adjustable test speed allows users to tailor testing conditions to their specific materials and standards.

- Multiple compatible compression plate shapes and sizes offer flexibility for diverse container types and dimensions.

- Safety and Convenience Features:

- Built-in overload protection and automatic return functions ensure operational safety and ease of use.

- Optional microprinter and RS232 data output port enable efficient data recording and reporting, with professional software for comprehensive data analysis.

Unique Testing Programs for Comprehensive Analysis

The Container Top Load Testing Machine is equipped with specialized testing programs, each designed for different analysis requirements:

- Peak Load Testing: Measures the maximum compressive force a container can withstand.

- Fixed Deformation Load Testing: Evaluates load capacity when the container reaches a specific deformation level.

- Fixed Load Testing: Measures the extent of container deformation under a constant load.

- Single and Cycle Compression Testing: Allows for single compression analysis or repeated compression cycles for in-depth structural resilience testing.

Technical Specifications

| Test Range | 0-1000N (or as required) |

| Sample Height | 700mm |

| Sample Diameter | 120mm max |

| Test Speed | 1~500mm/min |

| Displacement Accuracy | 0.01mm |

| Force Accuracy | 0.5% Full Scale |

| Control | PLC and HMI Screen |

| Data Output | screen, Microprinter (optional), RS232 (optional) |

| Power | 110~ 220V, 50/60Hz |

Compliance with Additional Standards

In addition to ASTM D2659, the Container Top Load Testing Machine supports testing compliant with several other standards to meet diverse industry needs:

- ASTM D4577: Guidelines for compression strength evaluation of packaging containers.

- ASTM D642: Methods for assessing the compressive resistance of packaging materials.

- ISO 8113: Specifies the top load compression strength test for rigid containers.

- ASTM D4169: Provides performance testing procedures for shipping containers and packaging systems.

Frequently Asked Questions (FAQs)

- What types of containers can be tested with this machine?

The machine can test various containers such as bottles, jars, cartons, and boxes made from plastic, glass, or other rigid materials, up to 120mm in diameter and 700mm in height. - How does this machine ensure compliance with ASTM D2659?

The machine is designed to follow ASTM D2659 testing methods, applying controlled, incremental compressive forces and recording maximum load capacity and deformation, ensuring accuracy in meeting the standard. - Can the testing parameters be adjusted?

Yes, the testing parameters, including test speed and sample height, can be adjusted to accommodate various container sizes and testing requirements. - Is it possible to integrate this machine with data management software?

Yes, the machine offers an RS232 data port for seamless integration with software systems, enhancing data recording and analysis capabilities. - How frequently should the machine be calibrated?

Regular calibration is recommended based on usage frequency, typically on an annual basis, to maintain optimal accuracy and compliance.

Cell Instruments’ Container Top Load Testing Machine is engineered to deliver precision, reliability, and flexibility to meet a wide range of testing needs. With options for customization, it adapts easily to unique client requirements, including special testing needs and automation transformation. Users benefit from expert guidance on setup, compliance with ASTM standards, and data interpretation, ensuring efficient integration into quality assurance workflows.