Introduction to Texture Analysers

A texture analyser is an advanced instrument used to evaluate the mechanical properties of various materials, with a primary focus on texture, consistency, and structural characteristics. By applying controlled forces to a sample and recording its deformation or response, the analyser provides valuable data that aids in understanding, refining, and optimizing product performance. Texture analysers are critical in industries such as food, pharmaceuticals, packaging, adhesives, and textiles, where they support quality assurance and guide product development to meet consumer preferences and market demands.

Applications of Texture Analysis

-

Food Industry

- Texture analysis plays a crucial role in food quality control, measuring properties like gel strength, hardness, crispiness, tackiness, elasticity, fracture force, and bending strength. These attributes are key indicators of a product’s quality and consistency, helping manufacturers ensure their products meet consumer expectations for texture and mouthfeel.

-

Medical and Pharmaceutical Applications

- In the medical and pharmaceutical sectors, texture analysers are essential for testing tablet compression strength, ampoule breaking strength, plaster adhesion, needle puncture force, and softgel hardness. These tests ensure that medical products perform reliably and consistently, meeting stringent regulatory standards and supporting patient safety.

-

Adhesives and Packaging

- For adhesive and packaging industries, texture analyzers measure loop tack and peeling force to determine bonding strength and material durability. These tests help improve product safety and quality while ensuring that adhesives and packaging materials perform as intended under real-world conditions.

Key Programs and Test Methods

Cell Instruments’ TEX-01 and TEX-02 Texture Analysers support a comprehensive suite of test programs that cater to diverse materials and industries. Key testing methods include:

- Gel Strength: Measures the firmness and strength of gel-like materials.

- Hold to Load and Hold Time: Assesses a material’s response to constant load over time.

- Fixed Deformation and Single Compression: Examines the material’s resistance and response to a single, controlled force.

- Hardness & Fracturability: Measures the hardness and brittleness of a sample, important in both food and pharmaceutical testing.

- Cycle Compression and Static Load: Provides insights into how a material performs under repeated stress or static pressure.

Models and Features of the Texture Analyzer

-

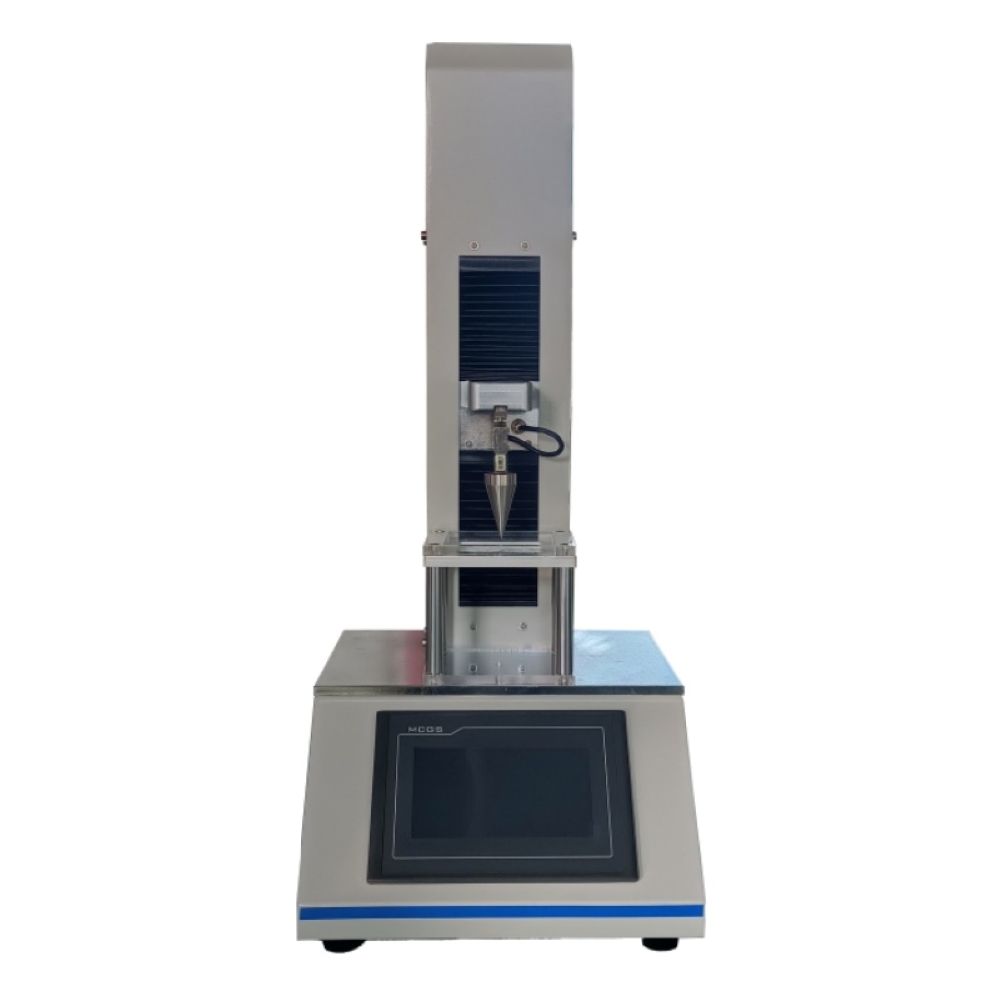

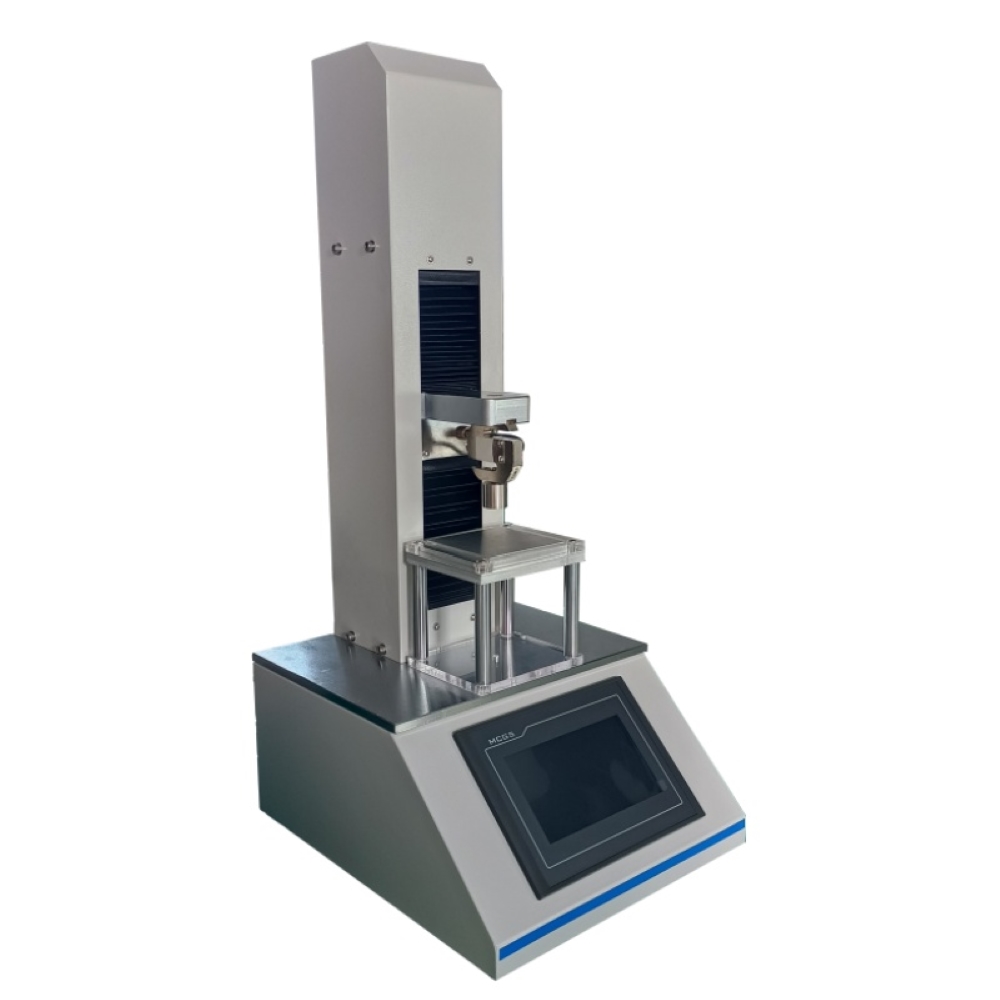

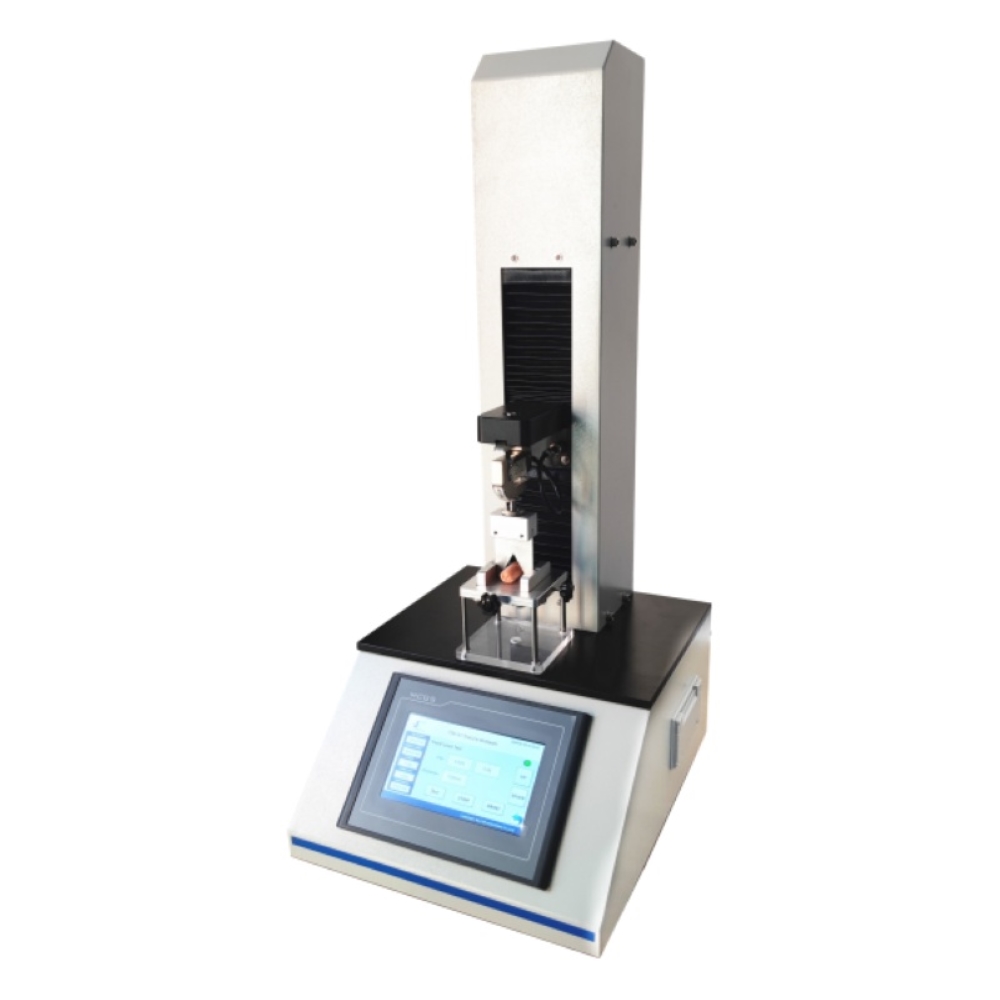

Overview of TEX-01 and TEX-02 Models

- The TEX-01 and TEX-02 texture analysers are versatile and reliable tools capable of testing a wide range of samples, including food items, packaging components, adhesives, tablets, and bottles. These models offer precision and flexibility, enabling manufacturers to meet specific testing requirements for various products.

-

Core Features and Benefits

- 7-inch HMI Touch Screen: This user-friendly display simplifies operation, reducing the learning curve and enhancing usability.

- PLC Control Unit: Ensures precise execution of complex testing sequences, delivering consistent and accurate results.

- Precision Ball Screw: Provides precise control over speed and displacement, enabling highly accurate and repeatable measurements.

- Adjustable Test Speed: Offers versatility in testing by allowing different speeds to match the requirements of diverse samples.

- Automatic Returning Function: Saves time and effort, particularly useful when performing multiple tests in quick succession.

- Micro Printer: Enables convenient, direct data recording for quick review and documentation.

- Optional Data Output Software: Allows for enhanced data management, analysis, and export, ideal for quality control and research purposes.

Advantages of Choosing a Texture Analyser for Product Development

- Consistency and Quality Control

-

- Texture analyzers ensure product consistency, a critical aspect of consumer satisfaction and regulatory compliance. These tools provide repeatable and precise measurements that help manufacturers achieve uniform product quality batch after batch.

-

Customization and Automation Capabilities

- With the ability to accommodate custom testing setups, our texture analyzers cater to specialized needs across industries. Additionally, automation options enhance productivity, streamlining the testing process to save time and labor.

Affordable Solutions: Finding a Cheap Texture Analyzer

Finding an affordable texture analyzer doesn’t mean compromising on quality. Our range of texture analszers includes options that balance performance and cost-effectiveness, making them accessible for businesses of all sizes. Models like the TEX-01 provide essential features for reliable testing without the high cost, allowing quality testing on a budget.

FAQ Section

- What is the purpose of a texture analyzer?

A texture analyser measures the mechanical properties of materials to assess texture, consistency, and structure, crucial for quality control and product development. - How does texture analysis benefit the food industry?

Texture analysis helps ensure that food products meet desired texture standards, which improves customer satisfaction by aligning with taste and quality expectations. - Can a texture analyzer measure adhesive strength?

Yes, texture analyzers can test adhesives, measuring properties like loop tack and peeling force to evaluate bonding strength and durability. - What is the importance of test speed in texture analysis?

Adjustable test speeds allow texture analyzers to simulate different real-world conditions, making them versatile for testing various materials and applications. - Are there cost-effective options for a texture analyser?

Yes, affordable models like the TEX-01 offer reliable performance for essential texture analysis, providing quality testing options at a budget-friendly price.

Texture analysers are essential tools for quality assurance, research, and product development in multiple industries. Cell Instruments’ TEX-01 and TEX-02 models deliver precise, reliable, and customizable texture analysis that meets industry standards. With robust features, flexible testing programs, and cost-effective options, our texture analysers empower manufacturers to meet stringent quality requirements and exceed customer expectations.