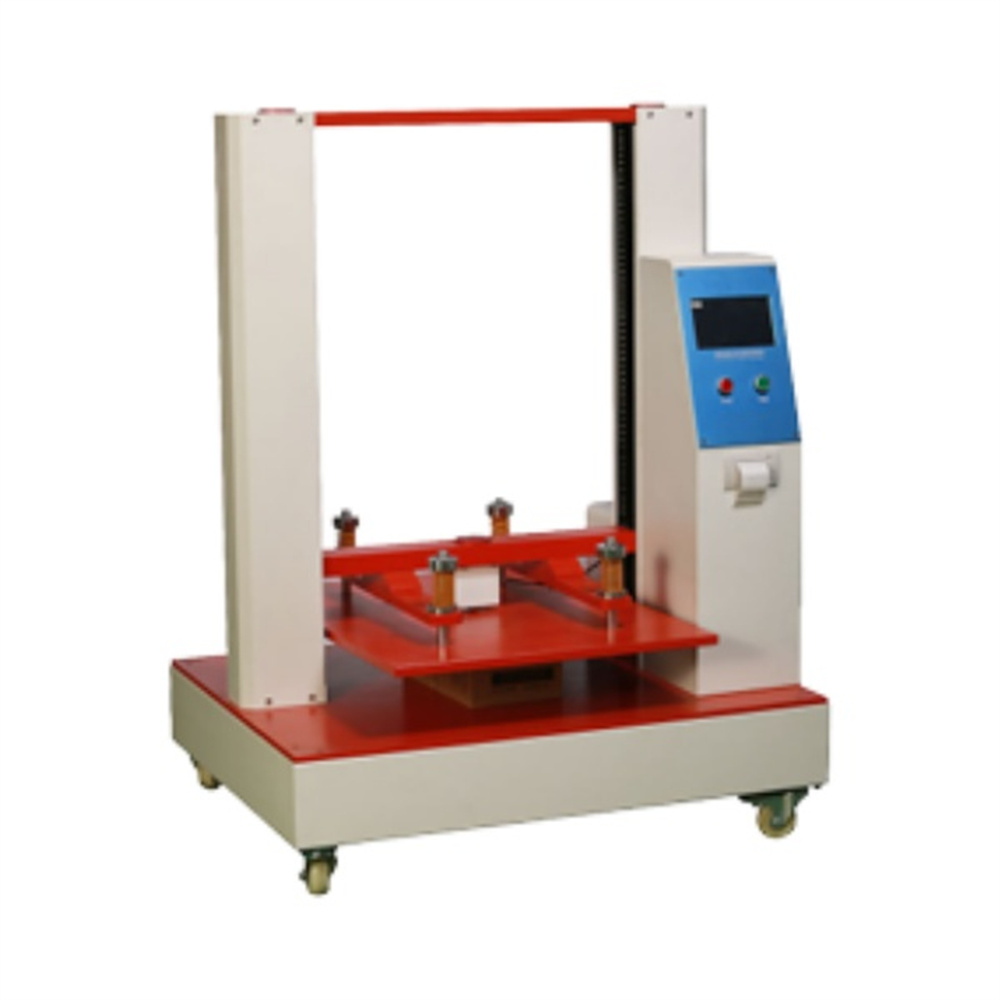

The Box Compression Tester is an essential instrument designed to evaluate the strength, durability, and resistance of packaging materials to external compressive forces. This advanced tester plays a critical role in industries such as food, electronics, pharmaceuticals, and packaging, ensuring that products are adequately protected during transport and storage. Its high precision, ease of use, and adherence to international standards make it an ideal solution for any company that values the integrity and reliability of its packaging.

Equipped with a user-friendly touch screen interface, a microcomputer processing system, and real-time data collection, the Box Compression Tester delivers precise results for a wide range of materials, including corrugated fiberboard, plastics, metals, and other packaging materials. The tester is designed for rigorous assessment, providing detailed insights into both the compressive strength and the protective qualities of packages under stacking conditions.

Application Scope of the Box Compression Tester

The Box Compression Tester is capable of handling an extensive variety of materials commonly used in packaging, from corrugated fiberboard to solid fiber cardboard, metal, and plastics. It assesses each material’s ability to resist compressive forces, allowing manufacturers to understand both the strength of the packaging itself and the level of protection it offers to the contents inside. This versatility is invaluable for industries that prioritize the safe and effective transportation of goods.

Key Test Modes and Capabilities

- Strength Test: This mode evaluates the ultimate compressive strength and deformation of the box or container by applying a gradual increase in pressure until the package collapses or deforms. This helps manufacturers determine the maximum load a package can endure.

- Fixed Value Test: In this mode, the tester measures the overall performance of a box or container by applying a set pressure and measuring any resulting deformation. This is particularly useful for companies needing to adhere to fixed strength requirements for their packaging.

- Stacking Test: The tester simulates a warehouse stacking environment by applying a steady, prolonged compressive force to evaluate how well a package performs under realistic storage conditions. This test is ideal for understanding stacking stability and predicting long-term package durability in storage.

Standards and Compliance

The Box Compression Tester is built to comply with leading international standards, ensuring that tests are conducted consistently and according to widely recognized industry specifications. Adherence to these standards makes it easier for manufacturers to meet regulatory and client requirements across multiple markets.

-

ISO Standards

- ISO 2234: Defines methods for stacking and compression tests, essential for assessing the package’s resilience to long-term loads.

- ISO 12048: Outlines procedures for testing a package’s stacking strength and resistance to load during storage and transport.

- ISO 2874: Specifically details compression testing methods for single packages, allowing for accurate measurement of compressive strength.

- ISO 2872: Evaluates a package’s ability to withstand compressive forces over time, predicting its performance in real-world scenarios.

-

ASTM Standards

- ASTM D642: This standard measures the compressive resistance of packaging materials, providing a baseline for transit packaging performance.

- ASTM D4169: Guides compression testing of containers in simulated distribution environments to ensure they can withstand actual handling conditions.

-

Other Relevant Standards

- TAPPI T804: Focuses on the compression strength of corrugated fiberboard containers, making it particularly relevant for shipping box evaluation.

- JIS Z0212: A Japanese standard detailing compression tests for packages, widely recognized across industries for its stringent requirements.

Technical Benefits of the Box Compression Tester

The Box Compression Tester integrates the latest technology to maximize precision, efficiency, and ease of use. Key benefits include:

- Advanced Technology Features: The touch screen operation allows for straightforward user interaction, while the microcomputer processing system automates data collection, calculations, and intelligent judgment of results.

- Enhanced Data Analysis: Real-time display of compression force, deformation, and curve visualization enhances users’ understanding of material behavior under stress. An embedded micro printer allows for easy record-keeping and quality control tracking.

- Compression Force Capacity: Handles a wide range of loads, suitable for testing light to heavy-duty packaging materials.

- Testing Area Dimensions: Provides ample space for testing various sizes and shapes of packaging.

- Drive System: A synchronous motor and accurate thread lead screw system ensure smooth, controlled force application for precise testing results.

Main Parameters

| Item | Parameters | |

| Test Range | 0.25KN, 0.5KN, 1KN, 2KN, 5KN, etc | |

| Resolution | 0.01N | |

| Deformation error | ≤±1mm | |

| Plate parallelism | ≤1mm | |

| Loadcell Error | ±1% | |

| Test Speed | 5~300mm/min | |

| Return Speed | 100mm/min | |

| Compression Speed | 10±3mm/min | |

| Stacking Speed | 5±1mm/min | |

| Units | N/Lbf /kgf | |

| Analysis | 7-inch touchscreen with curve analysis and integrated thermal printing | |

| Output | RS232 (optional) | |

| Power | AC 220V 50Hz | |

| Model | Test Space (mm, LWH) | Load (KN) |

| BCT-1500 | 1500*1500*1500 | 50 |

| 1500*1200*1500 | ||

| BCT-1200 | 1200*1200*1200 | 50 |

| 1200*1000*1200 | ||

| BCT-1000 | 1000*800*1000 | 20 |

| 1000*1000*1000 | ||

| BCT-800 | 800*600*800 | 20 |

| 800*800*800 | ||

| BCT-600 | 600*400*600 | 10 |

| 600*600*600 | ||

| BCT-500 | 500*500*500 | 5 |

Importance of Carton Compressive Strength Test in Industry

The carton compressive strength test is essential in ensuring packaging can endure stresses encountered during transport and storage. By identifying weaknesses before products reach customers, this test helps prevent packaging failure, reducing the risk of product damage, customer dissatisfaction, and financial losses. Industries such as pharmaceuticals, electronics, and food benefit greatly from understanding and meeting compressive strength standards, especially for high-value or perishable goods.

The Box Compression Tester offers a powerful solution for companies aiming to maintain high standards in packaging strength and integrity. By supporting compliance with ISO, ASTM, TAPPI, and JIS standards, this tester provides accurate, consistent results across diverse packaging materials and applications. With its advanced features and user-centric design, the Box Compression Tester is an invaluable tool for quality assurance in packaging, enhancing product safety and supporting operational efficiency.