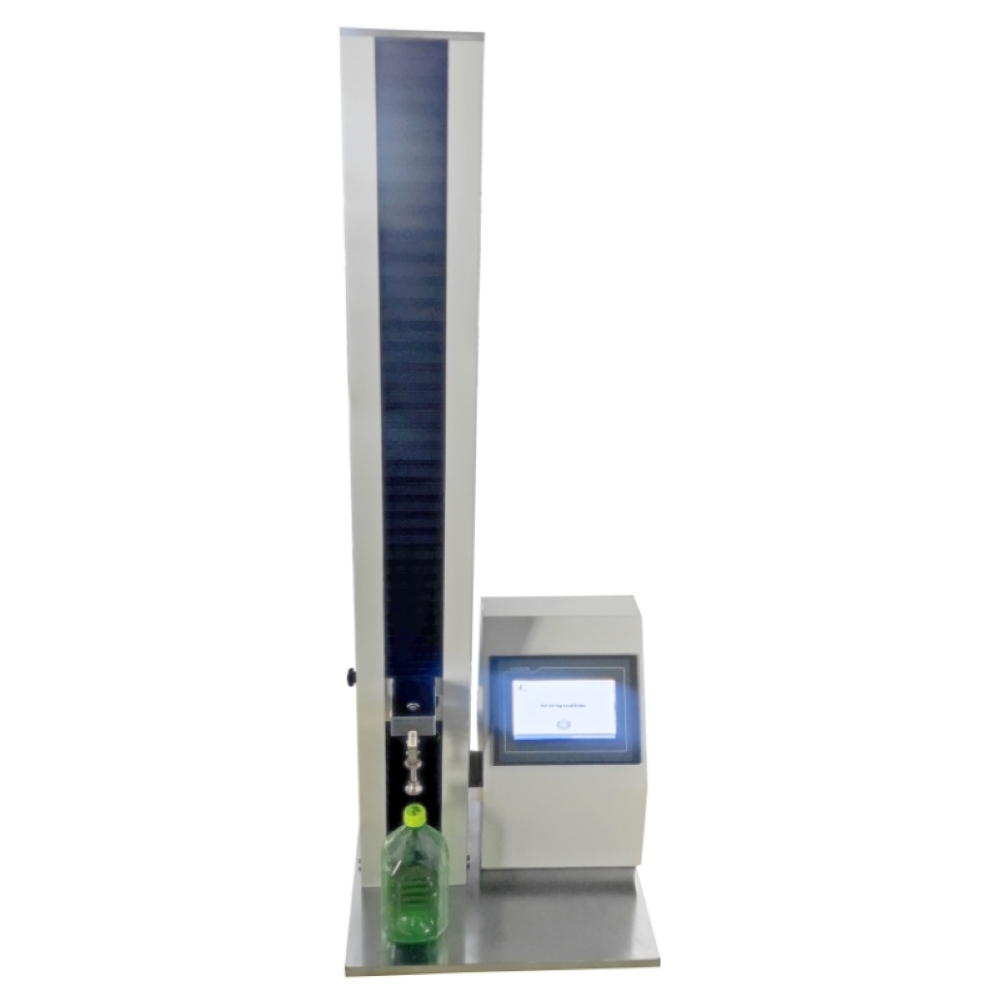

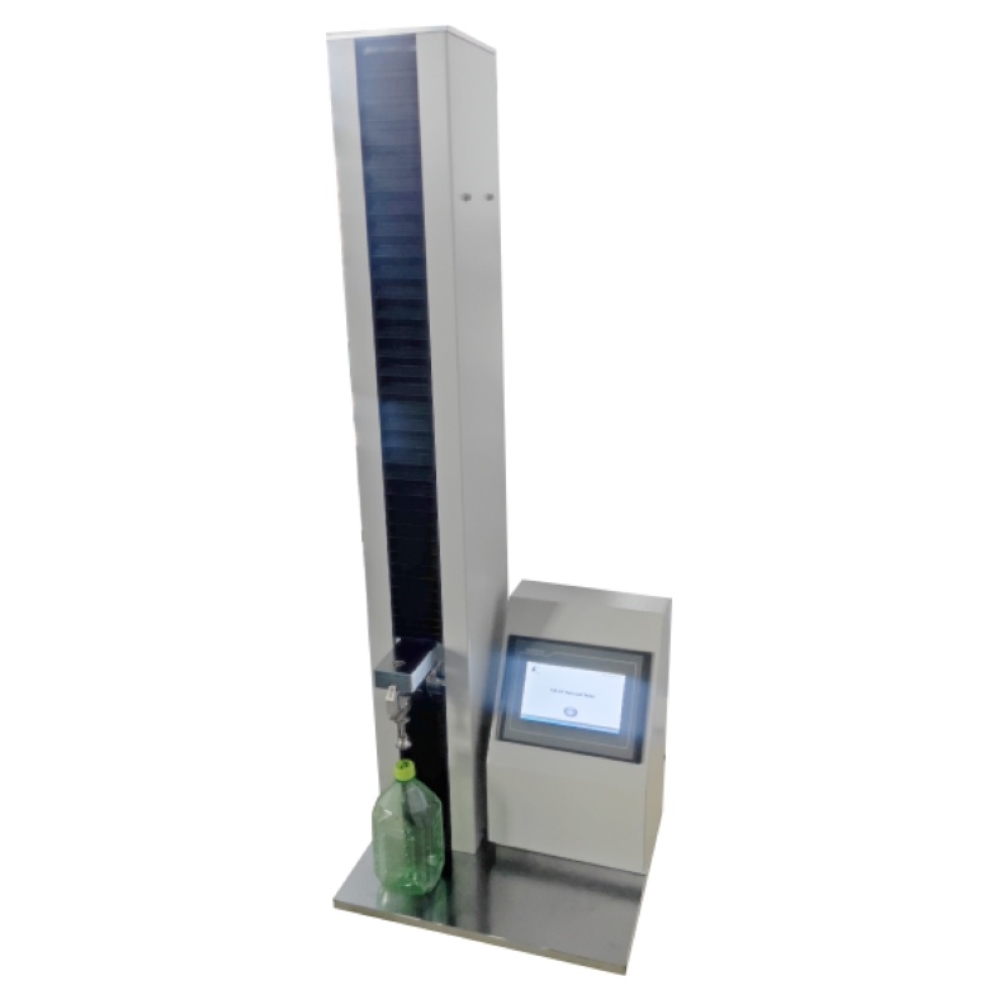

Introduction to the Bottle Crush Testing Machine

The Bottle Crush Testing Machine is a specialized instrument designed to assess the structural integrity and compressive strength of bottles and containers, including plastic, glass, and composite materials. By simulating top-load pressures similar to those encountered during stacking, shipping, and storage, this machine helps ensure that containers can withstand the stresses of distribution without collapsing or deforming. For industries such as packaging, food, beverages, and pharmaceuticals, bottle crush testing is essential to maintain product safety and minimize potential losses due to container failure.

Key Applications of Bottle Crush Testing

This machine serves a critical role across various industries, including:

- Packaging: Ensures packaging durability during storage and transportation.

- Food and Beverages: Prevents leakage and contamination by verifying container strength.

- Pharmaceuticals: Protects fragile and sensitive products during handling.

- Daily Chemicals and Cosmetics: Maintains brand reputation by confirming packaging quality.

Suitable for testing various container types, the Bottle Crush Testing Machine is highly versatile and capable of handling bottles, jars, cartons, drums, and more.

Technical Features of the Bottle Crush Testing Machine

Our Bottle Crush Testing Machine is engineered with advanced features to provide reliable, accurate results:

- PLC Control with HMI Touch Screen: A PLC control system ensures stable operation, while the 7-inch HMI touch screen enables intuitive and user-friendly testing.

- Precision Ball Lead Screw Mechanism: This mechanism guarantees consistent test speed and precise displacement control, improving the reliability of each test.

- Multiple Customizable Test Modes:

- Peak Mode: Measures maximum compressive load.

- Fixed Deformation Mode: Measures load at a set deformation.

- Fixed Load Mode: Monitors deformation under a constant load.

- Single Compression: Applies compression once for analysis.

- Cycle Compression: Repeats compression in cycles to evaluate resilience.

- Safety Features: Equipped with overload protection, automatic return functions, and compatibility with multiple plate sizes to accommodate various container shapes and dimensions.

- Data Management Options: Includes a microprinter for data output and an RS232 port for seamless data transfer, supporting external analysis with optional software integration.

Understanding the Plastic Bottle Top Load Test

The Plastic Bottle Top Load Test is vital for evaluating a bottle’s strength against vertical pressure applied from the top. This test, especially relevant to plastic bottles, assesses how much load the bottle can bear without deforming or collapsing. By quantifying the top-load resistance, manufacturers can optimize material use while ensuring containers remain robust enough for high-stress environments such as warehouse stacking and transport logistics.

Standards and Compliance: ASTM D2659 Explained

ASTM D2659 is a standard test method for determining the compressive resistance of plastic containers, specifically measuring their ability to endure top-load pressure without failure. In compliance with ASTM D2659, our Bottle Crush Testing Machine evaluates container durability by applying compressive forces from the top until structural deformation or collapse is observed.

This machine is also compatible with other industry standards, enhancing its versatility:

- ASTM D4577: Evaluates container performance under static load conditions.

- ASTM D642: Measures compressive resistance of shipping containers and boxes.

- ISO 8113: Tests for mechanical stability of packaging.

- ASTM D4169: Simulates distribution environment conditions to test packaging performance.

Working Principle of the Bottle Crush Testing Machine

The Bottle Crush Testing Machine operates by positioning the container on a testing platform and gradually applying top-load pressure until the container deforms or collapses. The machine records peak force data, which is analyzed to assess structural strength against specified standards like ASTM D2659. By providing precise, repeatable results, this machine ensures that manufacturers can validate packaging integrity for real-world handling.

Main Parameters of the Bottle Crush Testing Machine

This machine is highly configurable to accommodate various testing requirements:

- Load Range: High load range and precision suitable for different container types.

- Adjustable Speed: Allows for speed adjustments to match specific test protocols.

- Compression Plate Compatibility: Interchangeable plates to support different container sizes and shapes.

- Data Export Options: Microprinter and RS232 connectivity for efficient data handling.

Advantages of the Bottle Crush Testing Machine

- Cost Savings and Efficiency: Minimizes packaging material waste by confirming required strength, reducing costs associated with product returns and replacements.

- Reliability and Brand Protection: Enhances product reliability through accurate testing, helping to protect brand reputation and ensure consumer satisfaction.

FAQs about Bottle Crush Testing Machines

- What is the bottle crush test, and why is it important?

- The bottle crush test applies top-load pressure to assess container durability, ensuring the bottle can withstand handling stresses without breaking or deforming.

- How does ASTM D2659 apply to bottle crush testing?

- ASTM D2659 outlines procedures to evaluate the compressive strength of plastic containers, ensuring compliance with industry durability standards.

- What types of bottles can this machine test?

- This machine is versatile, supporting various bottle and container types, including plastic, glass, and composite bottles.

- How does the machine ensure accuracy in test results?

- With PLC control, precision lead screws, and multiple test modes, the machine delivers consistent, repeatable results for reliable performance assessments.

- What are the key features that make this machine reliable?

- Advanced PLC control, customizable test options, safety mechanisms, and extensive data management capabilities ensure accuracy, efficiency, and ease of use.