The Beverage Carbonation Tester is an essential instrument for ensuring quality and consistency in carbonated beverages. Designed to precisely measure CO₂ volume, this device supports producers in delivering products that meet both taste and safety standards. Used widely in the beverage industry, the carbonation tester assists with quality control and research by providing an efficient, reliable means of verifying carbonation levels in beverages like sodas, sparkling water, and flavored drinks.

Key Applications of the Beverage Carbonation Tester

The carbonation tester is invaluable across multiple industries, including food and beverage production, packaging, and quality control sectors. With its capacity to accurately gauge CO₂ levels, the tester ensures that beverages maintain their desired fizziness and flavor profile over time. This equipment is particularly beneficial for quality inspection agencies, bottling companies, and R&D labs in the beverage industry.

Overview of ASTM F1115 for Carbonation Testing

ASTM F1115, a recognized standard in beverage testing, outlines the methods for accurately determining carbonation volume in packaged beverages. It provides clear guidelines for measuring pressure and temperature, which are essential for precise carbonation assessment. By following ASTM F1115, beverage producers can ensure that their products achieve consistent quality and meet market standards.

Testing Procedure Using the Beverage Carbonation Tester

The beverage carbonation tester features a simple, yet effective process designed to yield accurate results. This step-by-step process is fully compliant with ASTM F1115 standards:

- Pierce the Bottle Cap: The tester starts by piercing the bottle cap to allow access to the beverage’s internal pressure.

- Open the Vent Valve: Release any excess pressure through the vent valve to stabilize conditions for measurement.

- Shake the Bottle: Perform vigorous shaking for 40 seconds to activate the release of dissolved CO₂.

- Close the Vent Valve: After the release phase, close the valve to prevent further pressure changes.

- Measure Pressure and Temperature: With pressure stabilized, record measurements in MPa or another applicable unit while measuring the liquid temperature simultaneously.

- Calculate CO₂ Volume: Use these values along with a carbonation volume table to determine the final CO₂ volume, providing a complete analysis of carbonation.

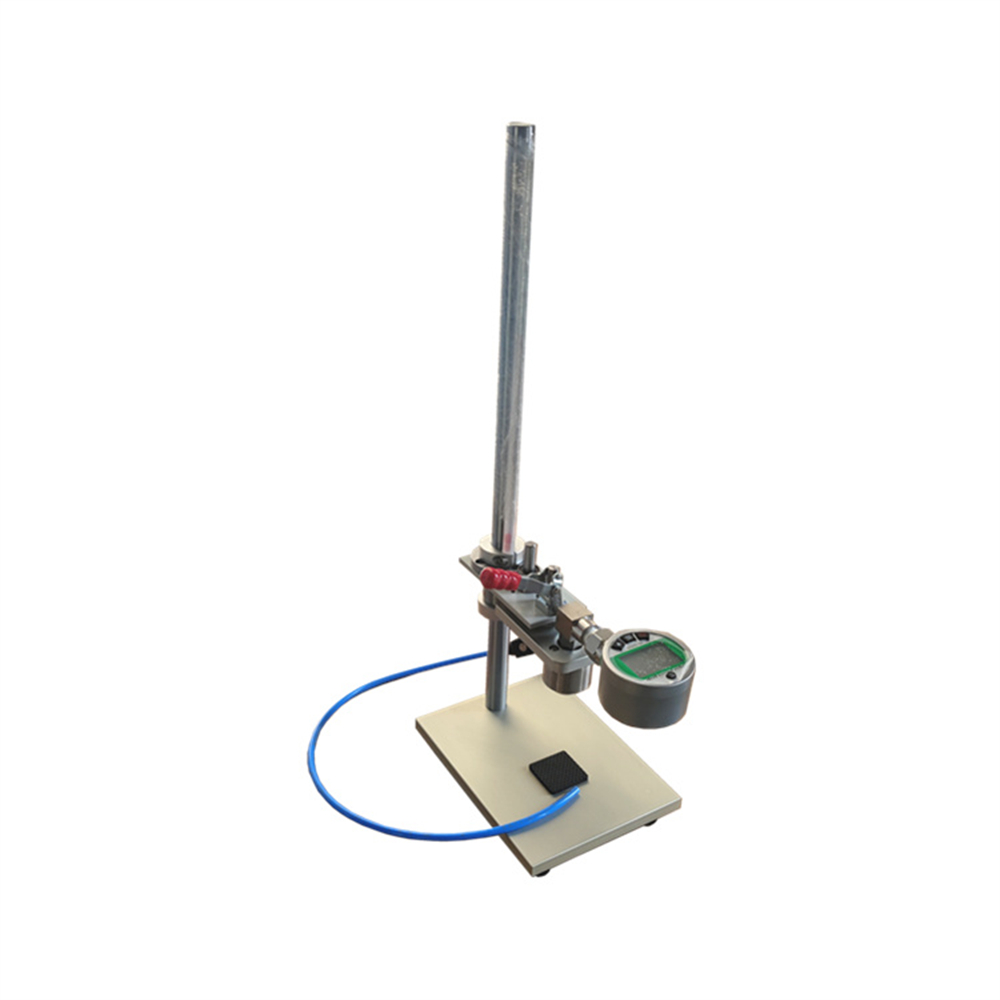

Technical Features of the Beverage Carbonation Tester

This carbonation tester is built for accuracy and ease of use, offering technical features that ensure reliable results with each test:

- Quenching Piercing Head: This durable piercing head is heat-treated for longevity and provides stable performance throughout the testing process.

- High-Precision Pressure Gauge: The pressure gauge allows multi-unit conversions, enabling easy interpretation across regions with diverse measurement standards.

- Anti-Leakage Design: A critical design feature, the anti-leak system maintains test integrity and prevents loss of CO₂, ensuring reliable results.

- Vent Valve and Pipe: Equipped with a vent valve and pipe, the tester allows controlled release of pressure to stabilize test conditions.

Main Parameters of the Beverage Carbonation Tester

The carbonation tester is suitable for testing a variety of beverage bottle sizes with a height of up to 350mm and offers the following key specifications:

- Test Range: 0~1MPa, covering standard carbonation levels in most beverages.

- Resolution: 0.0001MPa, ensuring precision in each measurement.

- Manual Shaking and Piercing: Provides users with control over the testing process, making the instrument versatile and adaptable.

Compliance with Major Standards (ASTM F1115, GB/T 10792)

This carbonation tester meets both ASTM F1115 and GB/T 10792 standards. While ASTM F1115 governs the testing methods in Western markets, GB/T 10792 is widely recognized in Asian markets. Compliance with these standards demonstrates the tester’s versatility and suitability for global quality control protocols, making it an ideal choice for international beverage producers.

Advantages of Using the Beverage Carbonation Tester

This carbonation tester offers many advantages for beverage producers seeking high-quality, consistent carbonation in their products:

- Accurate and Reliable Results: The tester’s design enables precision in CO₂ volume measurements, ensuring product quality and taste consistency.

- User-Friendly Design: With a straightforward testing process and durable construction, it facilitates efficient operation in both R&D and production settings.

- Enhanced Compliance: By adhering to ASTM F1115 and other relevant standards, the carbonation tester supports quality assurance and industry-standard compliance.

FAQ: Beverage Carbonation Tester and ASTM F1115

- What types of beverages can be tested?

The tester is ideal for carbonated beverages, including soda, sparkling water, and flavored drinks. - How does the tester maintain pressure accuracy?

It features a high-precision pressure gauge and anti-leak design to stabilize readings. - Why is ASTM F1115 important in carbonation testing?

ASTM F1115 outlines the necessary procedures for accurate carbonation volume measurement, ensuring reliable results. - Can this tester be used for different bottle sizes?

Yes, it accommodates bottle heights up to 350mm, making it versatile for various products. - How does manual shaking influence test accuracy?

Manual shaking ensures consistent release of CO₂, enabling a more precise measure of carbonation when used consistently.