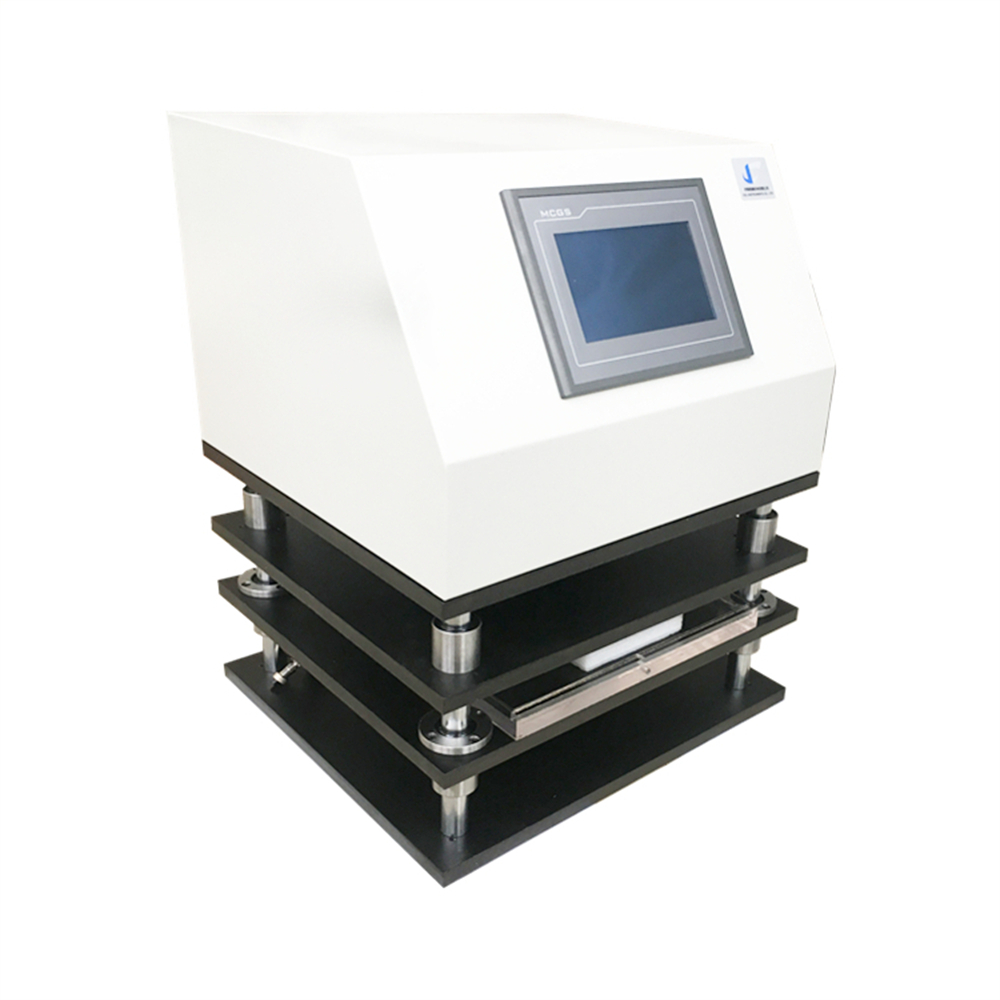

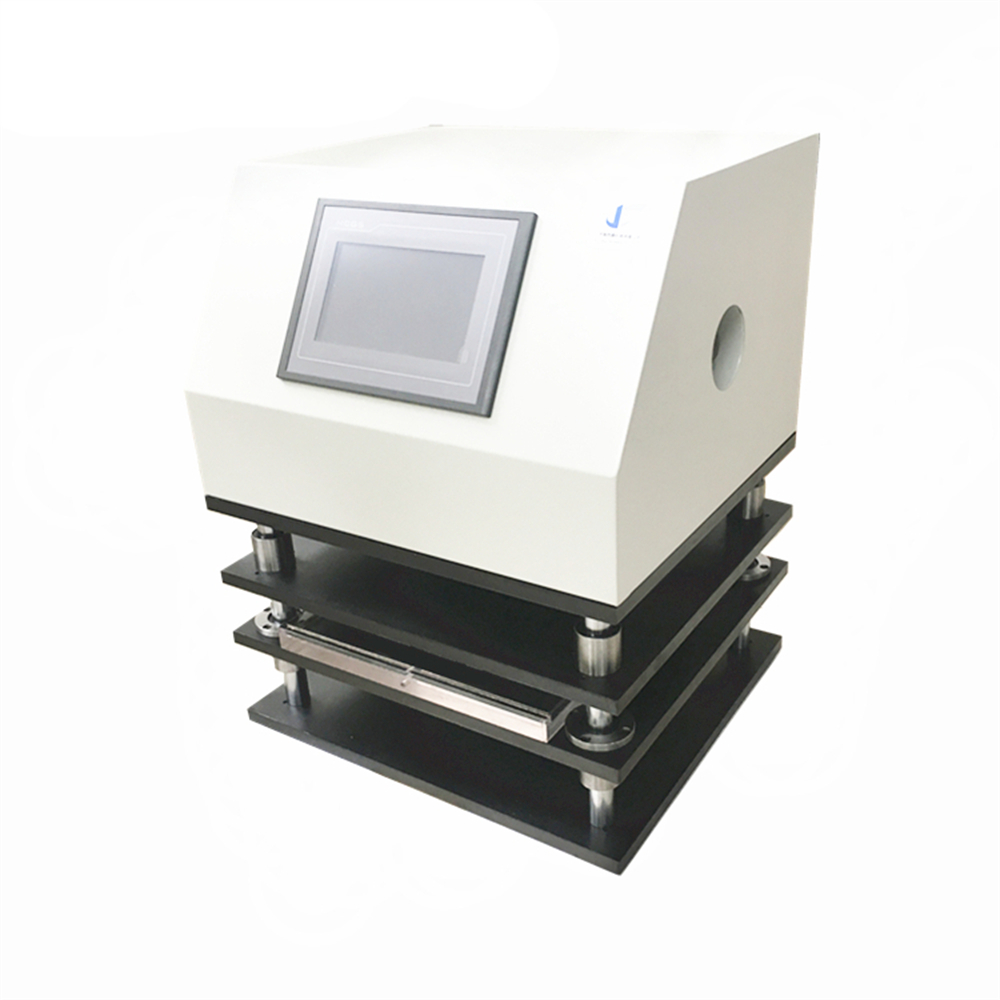

Introduction to the Bag Compression Tester

The Bag Compression Tester is a vital tool for quality assurance in packaging materials. As packaging integrity is critical in ensuring product safety and effectiveness, this instrument plays a crucial role across various industries, including food, pharmaceuticals, cosmetics, and medical packaging. Designed to assess the durability and performance of different packaging materials, the Bag Compression Tester ensures that products can withstand the rigors of transportation and storage.

Application of the Bag Compression Tester

This versatile and precision instrument is engineered to evaluate the pressure resistance of a wide range of packaging materials. It is particularly effective for testing composite film packs, infusion bags, plastic infusion bottles, blood bags, ice bags, and various containers. By simulating real-world conditions, the Bag Compression Tester helps manufacturers maintain product integrity and compliance with industry standards, thereby reducing the risk of packaging failures that could lead to costly recalls or safety issues.

Test Principle

Placement

The testing process begins with the placement of the sample material securely between the upper and lower pressure plates of the tester. This ensures accurate and consistent results during the compression test.

Compression

Once the sample is in place, the upper pressure plate is activated to move downward against the packaging material. This action simulates the external pressures that the packaging may encounter during handling, shipping, and storage, allowing for a realistic assessment of the material’s strength.

Force Measurement

As the compression occurs, the force exerted by the lower pressure plate is measured in real time. This data is crucial for evaluating the sample’s bursting performance and its ability to withstand constant pressure. The insights gained from these measurements inform manufacturers about the suitability of different materials and designs under stress conditions.

Test Methods

Package Compression Test

The package compression test is integral to the overall testing protocol. The Bag Compression Tester offers two primary test modes: maximum bursting force and constant pressure resistance. These methods provide essential data on how well different packaging materials can endure external forces, which is critical for ensuring product safety and compliance with industry standards.

Technical Features

- User-friendly HMI Touch Screen: Simplifies parameter setting and test operation for ease of use.

- Industrial-grade PLC Control System: Ensures reliable and precise control during testing.

- Two Test Modes: Options for maximum bursting force and constant pressure resistance.

- Automatic Constant Pressure Compensation: Adjusts pressure dynamically to maintain test accuracy.

- Data Statistics: Automatic data collection and analysis for streamlined reporting.

- Liquid Collection Device: Prevents contamination during sample rupture.

- Customizable Non-standard Test Sizes: Tailors testing capabilities to meet specific needs.

- Optional RS232 Port and Software: Provides advanced data analysis and integration options.

Main Parameters

| Measuring range | 2000N (other optional) |

| Measurement accuracy | 0.5% |

| Time range | 0~10000S |

| Platen size | 250mm*300mm (can be customized) |

| Power supply | 220V, 50HZ |

| Dimension | 460mm*410mm*590mm |

FAQs

- What types of materials can the Bag Compression Tester evaluate?

- The tester can assess a variety of materials, including composite films, plastic bags, and containers used in food, pharmaceuticals, and cosmetics.

- How is the package compression test different from other compression tests?

- The package compression test specifically evaluates the packaging’s ability to resist forces that may be encountered during transportation and storage, focusing on real-world applications.

- Can the Bag Compression Tester be customized for specific testing requirements?

- Yes, the Bag Compression Tester can be customized to accommodate non-standard test sizes and specific materials.

- What is the maximum force the tester can measure?

- The standard measuring range is 2000N, with options available for higher capacities.

- How does real-time data collection improve testing accuracy?

- Real-time data collection allows for immediate analysis of material performance under stress, enhancing the accuracy and reliability of test results.

The Bag Compression Tester is essential for enhancing packaging quality and ensuring that products can withstand various pressures during transit. By investing in this cutting-edge testing equipment, manufacturers can significantly reduce the risk of packaging failures, safeguard their products, and uphold their reputation in the market.