The Rub Tester is an essential tool for evaluating the resistance of ink films, coatings, and other materials against wear, scuffing, and rubbing. Designed for industries involved in packaging, printing, and material testing, the Rub Tester ensures that ink and coatings on various surfaces maintain their integrity under friction, moisture, heat, and other stress conditions. Whether testing printed packaging materials, labels, corrugated boards, or plastic films, the Rub Tester provides accurate insights into how these materials will perform during handling, transport, and use.

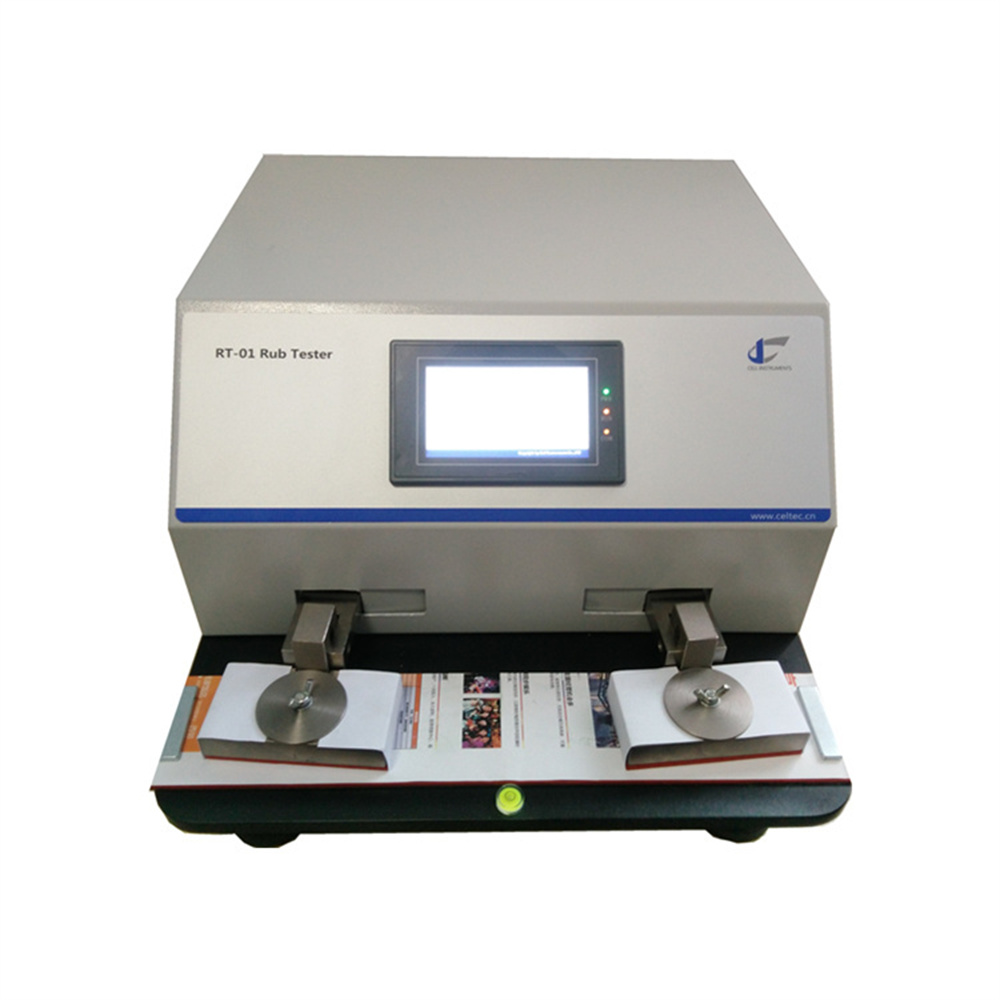

Introduction to the Rub Tester

The Rub Tester is a motor-driven, high-precision instrument that simulates repeated rubbing and scuffing actions on printed or unprinted materials. This testing method helps to assess how well ink and coatings withstand wear and tear under different conditions, making it indispensable in quality control and material testing. With customizable test configurations, the Rub Tester is ideal for evaluating ink performance, surface strength, and adhesion across a variety of materials, including paper, labels, packaging films, and corrugated boards.

Understanding ASTM D5264 and Ink Rub Tester Standards

ASTM D5264 is a widely recognized standard that defines the test methods for assessing the rub resistance of printed materials, coatings, and inks. By adhering to this standard, industries can ensure that their products meet the required durability benchmarks for ink performance under various conditions. This standard is crucial for manufacturers in the packaging, printing, and materials industries who rely on ink films that must resist wear, smearing, and fading.

- Dry Rub Test: This test evaluates how well the ink resists scuffing and abrasion under dry conditions. It simulates the friction that occurs during handling and transport.

- Wet Rub Test: This test assesses ink durability when exposed to moisture, simulating real-world conditions where inks may come in contact with water, oils, or other liquids.

- Heated Rub Test: This test examines ink and coating performance under elevated temperatures, which is particularly relevant for packaging that may be exposed to heat during storage or transit.

- Wet Bleed or Transfer: This test evaluates whether ink transfers or bleeds onto other surfaces when exposed to moisture.

- Wet Smear: This test simulates how ink behaves when wet, assessing how easily it smears or smudges under pressure.

- Functional Rub: This test simulates everyday handling and usage conditions, assessing the long-term durability of the ink and surface.

By using a Rub Tester that complies with ASTM D5264, manufacturers can accurately evaluate how inks and coatings will perform under various environmental and mechanical stress conditions.

The Significance of Rub Testing

Rub testing plays a vital role in ensuring the quality and durability of printed materials, coatings, and inks. The significance of rub testing lies in its ability to assess key factors such as:

- Ink Resistance: Rub testing reveals how well inks hold up to friction and wear, helping manufacturers ensure their products maintain a professional appearance throughout their lifecycle.

- Surface Strength: This testing method helps evaluate the strength of the substrate material, whether it is coated or unprinted paper, cardboard, or other materials. It gauges how well the surfaces hold up to external forces.

- Smearing and Bleeding: Rub testing helps detect potential issues like ink smearing or bleeding, which can negatively affect the appearance and quality of packaging and labeling.

- Heat Resistance: The heated rub test allows for the evaluation of how ink and varnishes perform under high temperatures, which is essential for packaging materials exposed to heat.

- Adhesion: Rub testing also distinguishes between strong and weak ink films, helping manufacturers identify inks with poor adhesion to substrates, ensuring the longevity of the printed materials.

Rub Tester Functionality and Testing Description

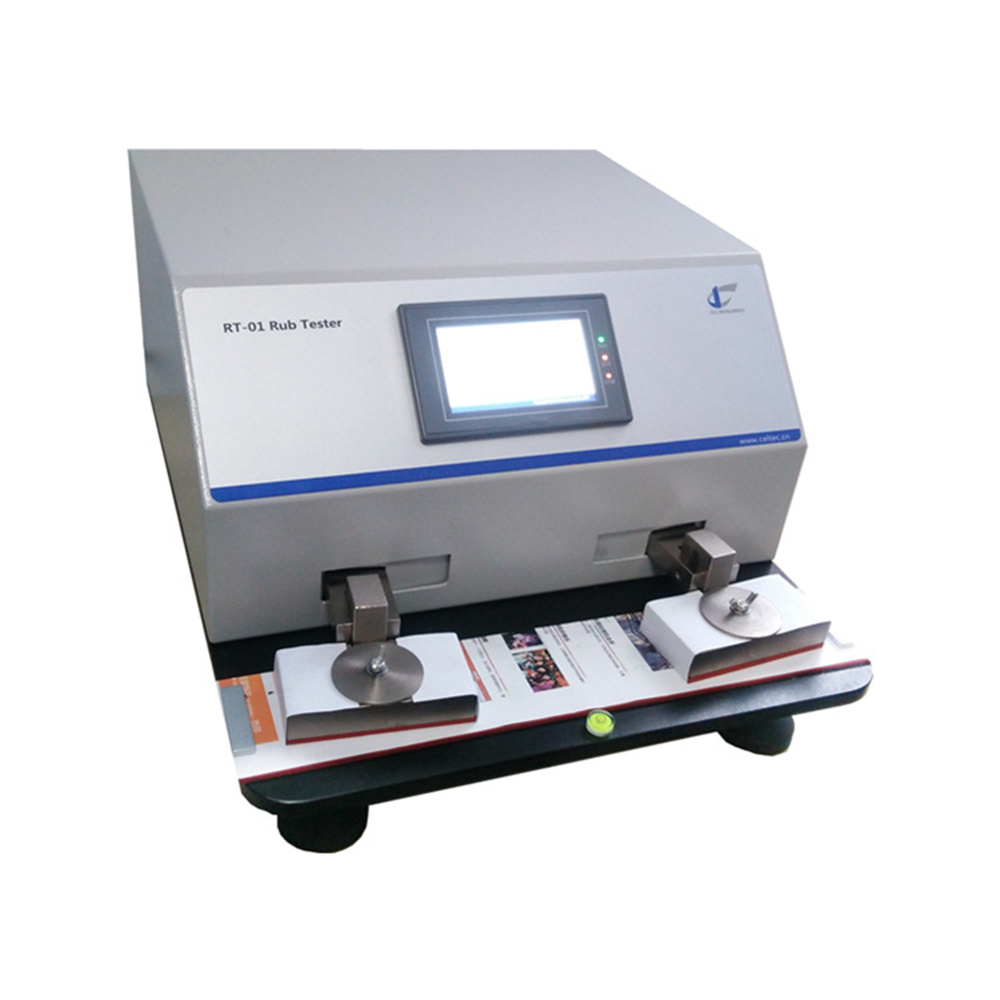

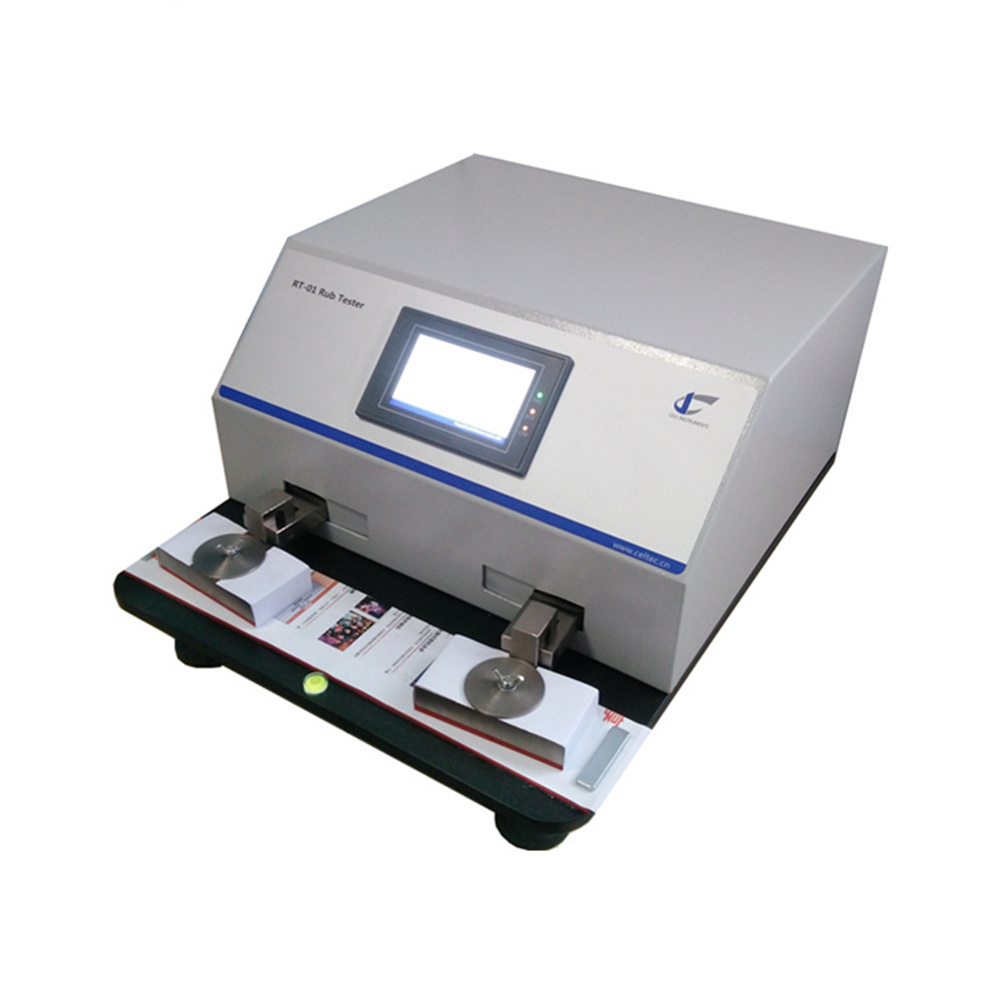

The RT-01 Rub Tester is an advanced, motor-driven testing machine designed to simulate the rubbing action on printed or unprinted surfaces. The tester features a weighted specimen that moves in a precise 57mm arc over the test sample for a predetermined number of strokes. This replicates the conditions under which inks or coatings are subjected to friction, helping to predict how the material will hold up during actual use.

Testing Methods include:

- Dry Rub: Tests ink resistance to abrasion under dry conditions.

- Wet Rub: Simulates the effects of moisture on ink durability.

- Heated Rub: Evaluates ink performance under high temperatures.

- Wet Bleed/Transfer: Assesses whether ink bleeds or transfers onto other surfaces under wet conditions.

- Wet Smear: Determines how the ink behaves when exposed to moisture.

- Functional Rub: Tests for long-term durability under regular handling conditions.

Key Technical Features of the Rub Tester

- PLC Controlled Unit: The Rub Tester is equipped with a PLC (Programmable Logic Controller) for industrial-level stability and reliability, ensuring consistent, accurate results with every test.

- HMI Touch Screen Operation: The user-friendly Human-Machine Interface (HMI) touch screen allows easy operation, test configuration, and monitoring of results.

- Versatile Testing: The Rub Tester can perform various types of tests, including dry rub, wet rub, heated rub, and functional rub, making it adaptable to a wide range of testing needs.

- Test Speed Adjustment: The speed of the rub test can be adjusted between 20-120 strokes per minute, providing flexibility for different test requirements.

- Double Test Station: With a dual test station, the Rub Tester can simultaneously test two specimens, increasing testing efficiency.

- Precise Rub Circle Control: The device provides precise control over the rubbing circle, ensuring accurate and repeatable test results.

Test Samples and Applications

The Rub Tester can test a variety of materials, including:

- Inks: To assess their resistance to abrasion, smearing, and wear.

- Coatings: To evaluate the durability and adhesion of printed coatings.

- Plastic Films: To determine how well printed films withstand rubbing and friction.

- Paper: Including coated and uncoated paper used in packaging and labels.

- Packaging Materials: Corrugated boards, cartons, and other packaging materials that may come into contact with friction during handling or shipping.

- Labels: To check the quality and durability of printed labels exposed to abrasion.

Industries that benefit from rub testing include:

- Packaging: Ensuring printed packaging materials retain their appearance and functionality.

- Food and Beverages: Verifying the durability of printed labels and packaging in contact with moisture or heat.

- Medical and Pharmaceutical: Ensuring the integrity of printed materials on medical packaging.

- Textiles and Plastics: Testing printed textiles and plastic films for long-term durability.

Standards and Compliance

The Rub Tester complies with several important industry standards:

- ASTM D5264: This standard provides the testing methods for rub resistance of printed materials and coatings.

- Other Relevant Standards: The Rub Tester also aligns with standards such as TAPPI T830, ASTM F1571, FINAT FTM 27, and JIS K 5701, ensuring global compatibility and accuracy.

Main Technical Parameters

| Weights | 908g (2lb) /8.9N;1816g(4lb) /17.8N |

| Speed | 20~120 cpm free setting |

| Number of Specimens | 1~2 |

| Rotation Radius | 185 mm |

| Arc Length | 57 mm ± 1 mm |

| Dimension | 390x480x220 mm (LWH) |

| Power | 110~220V 50/60Hz |

The RT-01 Rub Tester offers advanced functionality and precise control to evaluate the durability of printed materials and coatings under various conditions. With its versatile testing options, easy operation, and compliance with key standards like ASTM D5264, the Rub Tester is an indispensable tool for industries requiring robust quality control of inks and coatings. It helps ensure the durability and visual appeal of packaging, labels, and printed materials, making it an essential investment for manufacturers in a wide range of industries.

FAQs

- Q1: What is the ASTM D5264 standard used for?

- ASTM D5264 is used to test the rub resistance of printed materials and coatings, ensuring their durability during handling, transport, and use.

- Q2: How does the Rub Tester measure ink resistance?

- The Rub Tester simulates repeated rubbing actions on the ink film to measure its resistance to scuffing, smearing, and fading under dry, wet, and heated conditions.

- Q3: What types of surfaces can be tested with the Rub Tester?

- The Rub Tester can test various surfaces including paper, plastic films, labels, packaging materials, and corrugated boards.

- Q4: Can the Rub Tester perform both dry and wet rub tests?

- Yes, the Rub Tester is capable of performing dry, wet, heated, and functional rub tests, making it adaptable to various testing needs.

- Q5: How does the RT-01 Rub Tester ensure consistent results?

- The RT-01 Rub Tester features a PLC-controlled system, precise rub circle control, and an adjustable test speed to ensure accurate, reproducible test results.