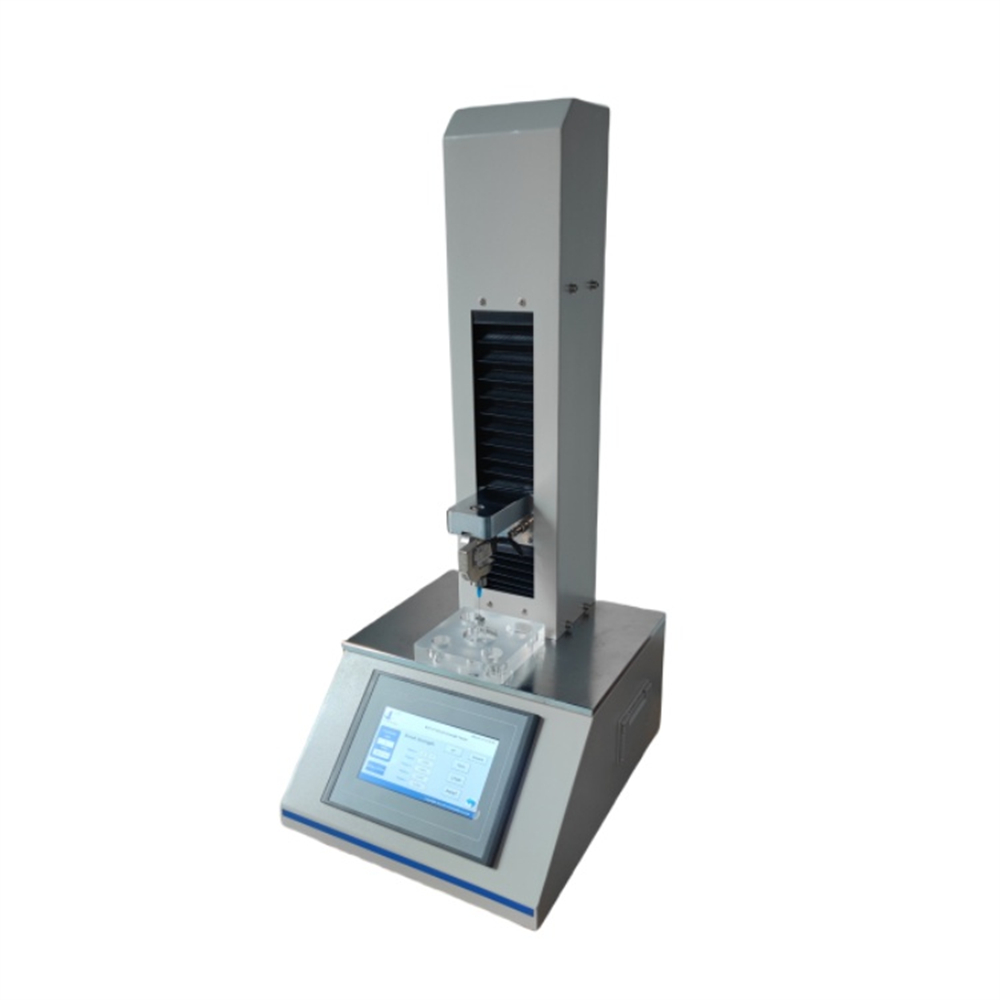

Introduction of NPT-01 Medical Needle Puncture Tester

In the realm of medical device testing, precision and reliability are very important. Cell Instruments, an advanced manufacturer of materials testing instruments, presents a solution in medical safety – the Medical Needle Puncture Tester. Tailored to meet the rigorous demands of the medical industry, this cutting-edge device ensures the integrity and safety of medical needles during use, enhancing patient care and confidence in medical procedures.

Why choose NPT-01 Medical Needle Puncture Tester?

The Medical Needle Puncture Tester stands out as an indispensable tool for medical device manufacturers, quality inspection agencies, and healthcare facilities alike. Here are the benefits the medical needle puncture tester brings:

1. Quality Control

Biding by strict regulations in the medical device sector, to guarantee the dependability and safety of medical needles. The Medical Needle Puncture Tester enables companies to adhere to industry standards and maintain top-notch quality.

2. Accurate Examination

Precision holds paramount importance in medical diagnosis and therapy. The adoption of this advanced testing device can carry out meticulous puncture assessments on medical needles, ensuring peak functionality and reducing the likelihood of mishaps during medical procedures.

Main Functions

1. Application of Needle Puncture Resistance Tester

This tester is specifically designed to evaluate the puncture resistance of medical needles, including but not limited to hypodermic needles, injection needles, acupuncture needles, and biopsy needles. Its versatility enables comprehensive testing across various needle types and sizes, ensuring a thorough evaluation of product performance.

2. What Benefits Can be Obtained?

By using the Medical Needle Puncture Tester, users can derive several noteworthy benefits:

- Improved Safety: Putting patient safety first, this tool aids in spotting any problems or flaws in medical needles, reducing the chance of needles breaking or not working properly during medical procedures.

- Meeting Regulations: In a field that’s becoming more regulated, it’s crucial to meet strict standards. This tester makes it easier to follow the rules and standard, preventing possible legal issues and keeping the product reliable.

- Cost Savings: Finding needle issues early through thorough testing saves money for companies. It lowers the risk of having to recall products, deal with lawsuits, and damage their reputation.

How to use NPT-01 Medical Needle Puncture Tester

1. Operation Process

Engineers implemented an easy-to-operate human-computer interaction interface through the PLC control unit. Therefore the operation of the medical needle puncture tester is very simple:

- Secure the medical needle specimen and punctured samples in the designated fixture.

- Adjust the testing parameters, including puncture force and speed, to align with specific testing requirements.

- Initiate the testing process, allowing the device to assess the needle puncture resistance.

- Evaluate the test results to determine the needle’s performance and identify any deviations from the expected standards.

2. Video Reference about NPT-01 Medical Needle Puncture Tester

Common Applications

The versatility of the Medical Needle Puncture Tester renders it indispensable across various applications within the medical industry:

- Quality Control in Manufacturing: Medical device manufacturers rely on this tester to conduct thorough quality assessments of medical needles, ensuring compliance with regulatory standards and maintaining product excellence.

- Research and Development: In the pursuit of innovation, researchers leverage the tester to evaluate novel needle designs and materials, enhancing the efficacy and safety of medical devices.

Main Parameter

| Test Range | 0~200N (Or as required) |

| Stroke | 200mm (without clamp) |

| Speed | 1~500mm/min(or as required) |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~ 220V 50/60Hz |

Manufacturing Process

Pre-sales Support

After-sales Service

Main Standard

Recommended Article

3 Reasons to Test Needle Puncture Resistance

What is Penetrability Testing? | ISO 8871-5

Penetrability Tester for Vial Stopper | ISO 8871-5

Needle Penetrability Tester for Vial Stopper | ISO 8871-5

Best ISO 8771-5 Needle Penetration Test Equipment

How To Use Penetration Force Tester To Meet ISO 8871-5

Needle Penetration Test for Vial Stopper Quality Assurance ISO 8871-5

Needle Penetration Test Method for Rubber Stoppers