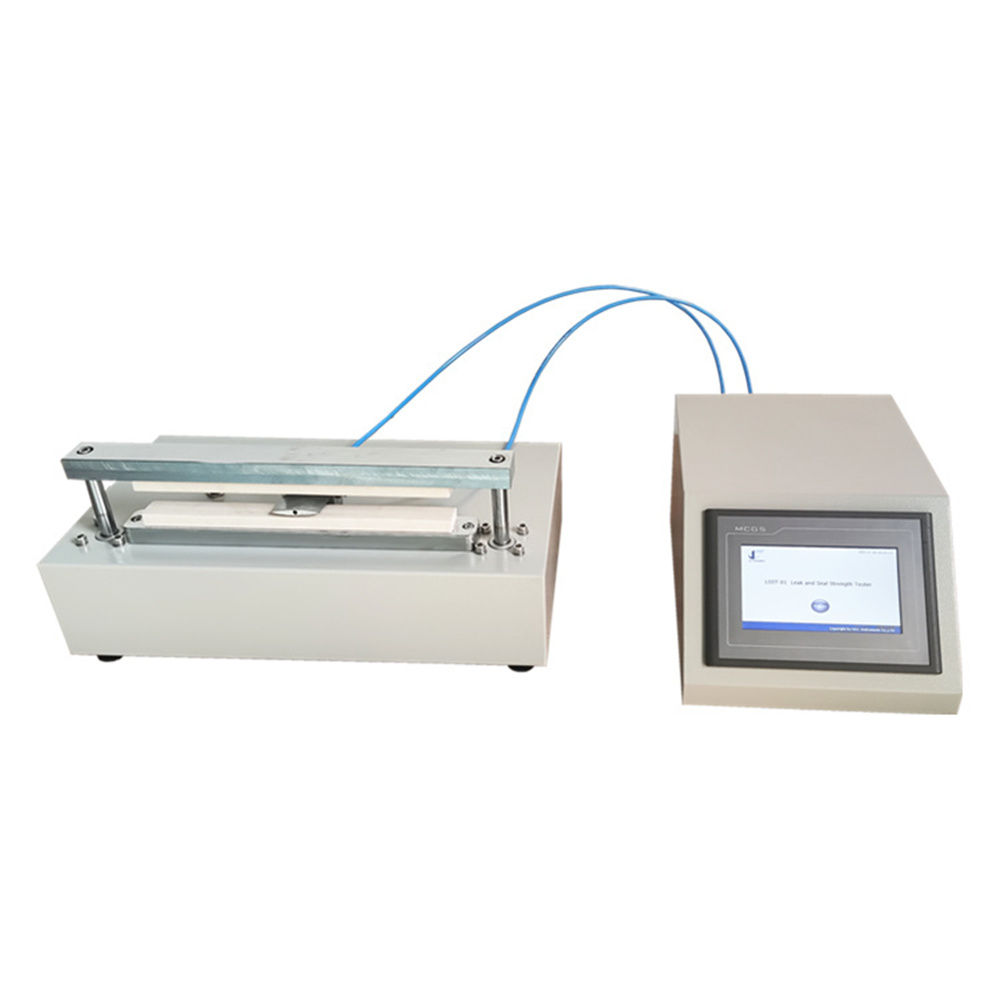

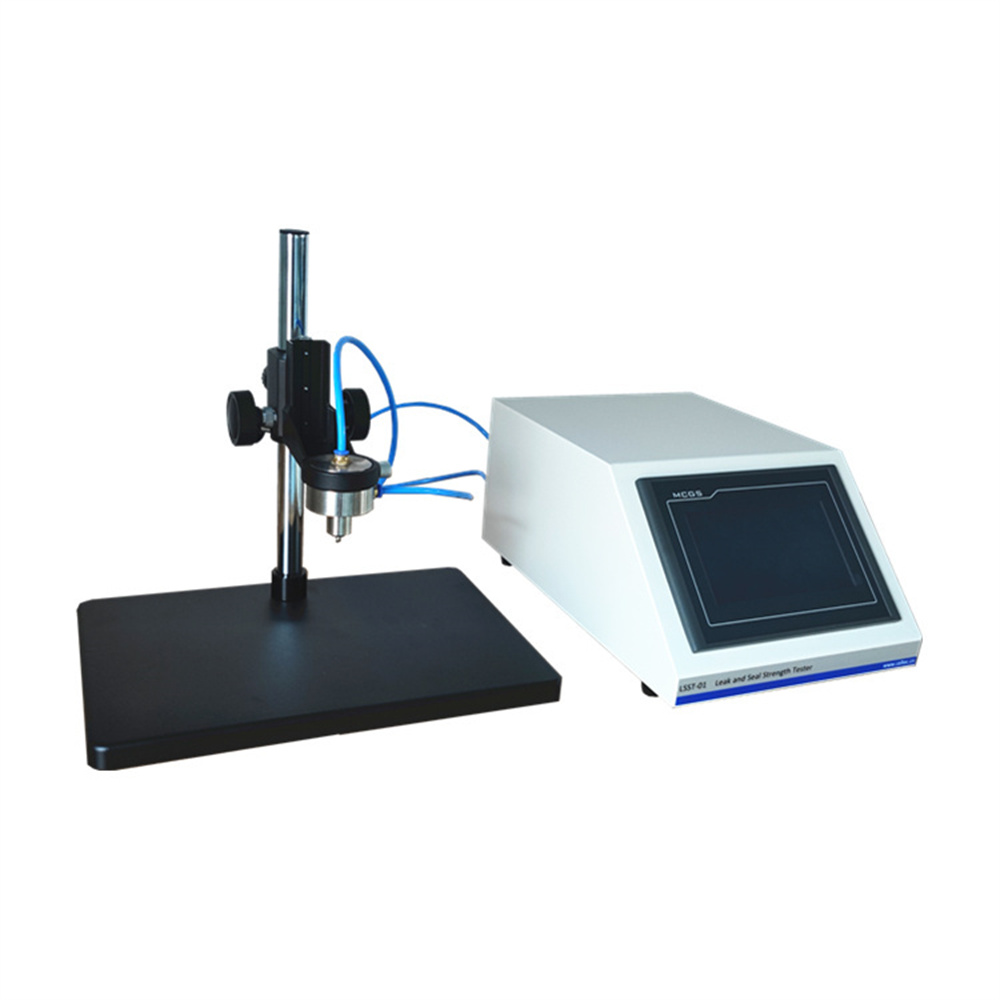

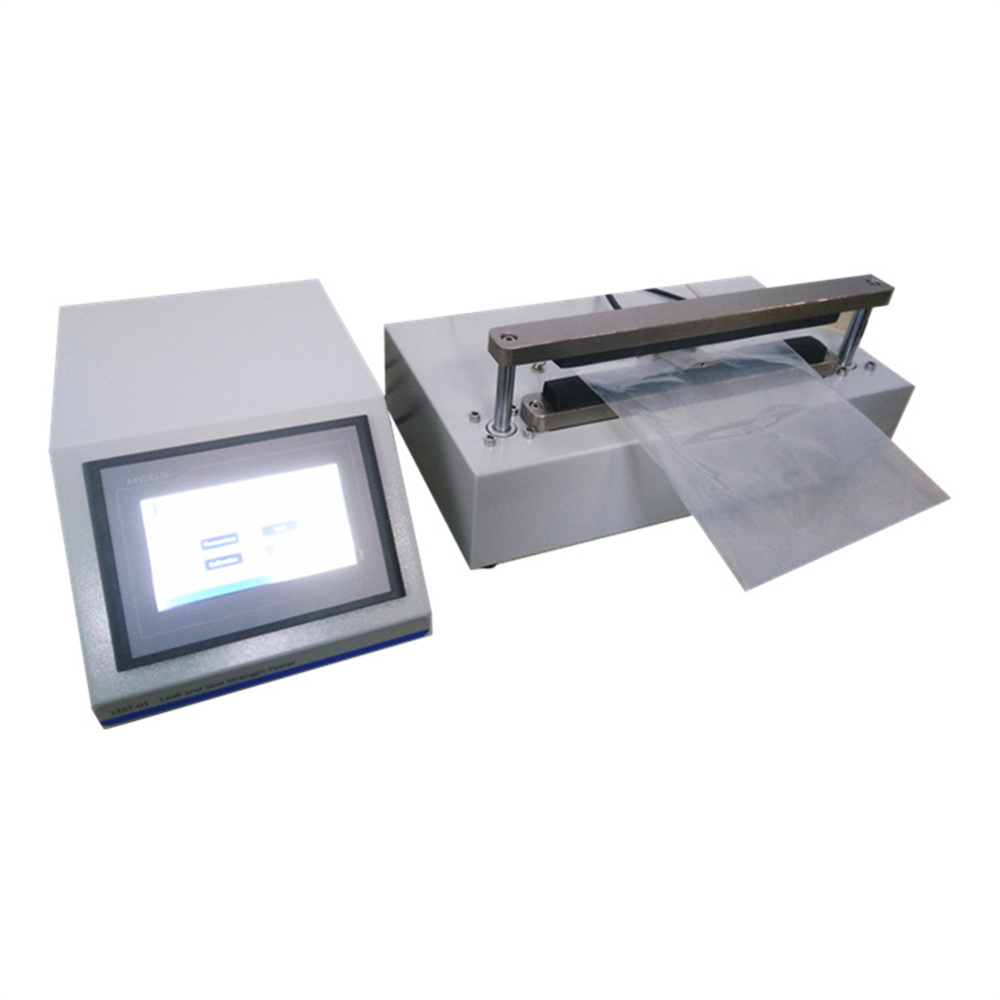

LSST-01 Leak and Seal Strength Tester

Balloon Burst Tester is a critical instrument in material and packaging testing, designed to measure the burst strength of various packaging materials. This advanced equipment is pivotal in ensuring the durability and reliability of packaging, particularly in industries such as pharmaceuticals, food and beverages, medical devices, and consumer goods. The Balloon Burst Tester stands out for its precision, versatility, and compliance with industry standards, making it an indispensable tool for quality assurance.

The Balloon Burst Tester is versatile, finding applications across various sectors, packaging materials, including plastic films and laminates, medical device packaging, pharmaceutical packaging, food and beverage packaging, consumer goods packaging

Full Introduction to the Balloon Burst Tester

The Balloon Burst Tester is engineered to provide precise and reliable burst testing for a wide range of packaging materials. It is a PLC-controlled unit that offers industrial-level stability, complemented by a user-friendly HMI touch screen for easy operation. The tester is equipped with automatic test result statistics and storage, enhancing efficiency and data management.

Technical Specifications

- PLC-Controlled Unit: Ensures industrial-level stability and precise control.

- User-Friendly HMI Touch Screen: Simplifies operation and reduces training time.

- Automatic Test Result Statistics and Storage: Facilitates efficient data management and analysis.

- Compatibility with Various Fixtures: Allows testing of different package forms, including three-side-seal packages, closed packages, doy packs, tubes, sealed trays, and cups.

- Three Test Modes: Burst, creep, and creep to failure, catering to diverse testing requirements.

- Personalized Sensitivity and Threshold Settings: Enables customization for specific testing needs.

- Pressure Range Up to 600 KPa: Customizable to meet unique testing specifications.

- Customizable Programming: Provides flexibility to adapt to specific testing protocols.

Test Methods

Principle of Packaging Burst Testing

The Balloon Burst Testing method involves inflating a package until it bursts, measuring the pressure and volume at which the burst occurs. This test is crucial for evaluating the burst strength of packaging materials, ensuring they can withstand internal pressure during handling and storage.

Standard Test Procedures

- Sample Preparation and Conditioning: Samples are prepared according to specified standards and conditioned to the appropriate environment before testing.

- Test Setup and Parameters Configuration: The balloon burst tester is set up with the appropriate fixtures, and test parameters are configured based on the sample type and testing requirements.

- Execution of the Test and Measurement Recording: The package is inflated until it bursts, with the tester recording the burst pressure and volume.

- Interpreting Results: Burst pressure and volume are analyzed to assess the material’s strength and performance, facilitating quality control and material comparison.

Packaging Burst Testing in ASTM Standard

ASTM F1140

-Standard Test Methods for Internal Pressurization Failure Resistance of Unrestrained Packages

- Overview of ASTM F1140: This standard outlines the methods for testing the internal pressurization failure resistance of unrestrained packages.

- Detailed Test Procedure as per ASTM F1140: Involves inflating the package until it bursts and recording the burst pressure and volume.

- Importance of Compliance with ASTM F1140: Ensures packaging integrity and reliability, critical for product safety and performance.

ASTM F2054

-Standard Test Method for Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining Plates

- Overview of ASTM F2054: This standard specifies the method for burst testing flexible package seals using internal air pressurization within restraining plates.

- Detailed Test Procedure as per ASTM F2054: Involves placing the package within restraining plates, inflating it, and recording the burst pressure and volume.

- Significance of ASTM F2054: Essential for assessing seal strength and ensuring package integrity, particularly for flexible packaging.

Advantages of Using Our Balloon Burst Tester

1. Precision and Reliability

- High Accuracy in Measurements: Ensures precise and reliable burst strength data.

- Consistent and Repeatable Results: Provides confidence in test results and material performance evaluation.

2. Versatility

- Suitable for a Wide Range of Materials and Packaging Types: Accommodates various testing requirements across different industries.

- Adjustable Test Parameters for Different Testing Requirements: Offers flexibility in testing diverse materials and packages.

3. Ease of Use

- Intuitive Software Interface: Simplifies operation and reduces the learning curve.

- Minimal Training Required for Operators: Enhances usability and efficiency.

4. Compliance

- Meets ASTM F1140 and ASTM F2054 Standards: Ensures adherence to industry standards and regulations.

- Ensures Compliance with Industry Regulations and Quality Standards: Guarantees the reliability and integrity of test results.

FAQs

What is the purpose of a balloon burst test?

The balloon burst test is used to determine the packaging burst test, ensuring they can withstand internal pressure during handling, storage, and transportation.

How does the balloon burst tester measure burst strength?

The tester inflates the package until it bursts, recording the burst pressure and volume to evaluate the material’s strength and performance.

What types of materials can be tested with the balloon burst tester?

The tester can evaluate a wide range of materials, including plastic films, laminates, medical device packaging, pharmaceutical packaging, food and beverage packaging, and consumer goods packaging.

Related Products