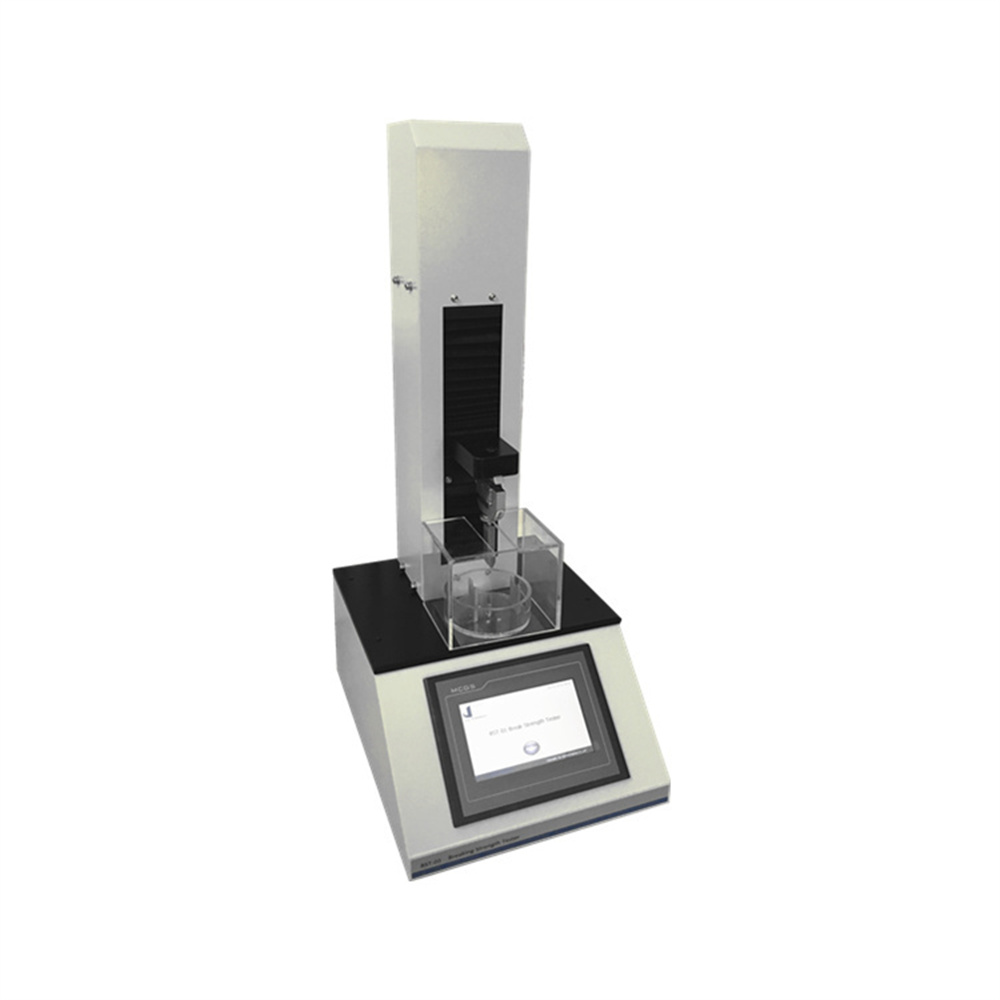

Introduction to the Ampoule Break Force Tester

The ampoule break force tester is a crucial tool in the pharmaceutical and medical packaging industries, designed to measure the force required to break the neck of an ampoule. Ampoules are hermetically sealed containers used for storing sensitive pharmaceutical substances. The breaking strength of the neck plays a critical role in ensuring the safety and integrity of the product inside. A precise and reliable tester is essential to ensure ampoules meet the necessary standards for safe use and handling.

Understanding ISO 9187: Standard for Ampoule Break Force Testing

ISO 9187 is the international standard that specifies the method for testing the breaking force of ampoules. It provides detailed guidelines on how the testing process should be conducted, the necessary equipment, and the parameters to be measured to ensure consistent and accurate results. By following ISO 9187, manufacturers can be confident that their ampoules will meet safety requirements, reducing the risk of breakage during storage and handling.

Test Method According to ISO 9187

The test involves placing an ampoule on a fixture and applying a downward force to the neck using the testing machine. The BST-01 Ampoule Break Force Tester uses a high-precision load cell to measure the force required to break the neck of the ampoule. The test ensures the ampoules are not only safe to handle but also meet the required standards for pharmaceutical applications.

Test Process of the Ampoule Break Force Tester

- Step 1: Place the ampoule on the dedicated fixture designed for different ampoule sizes (1ml, 2ml, 5ml, 10ml, 20ml).

- Step 2: Start the test, where the pressing head moves down at a consistent rate of 10 mm/min (adjustable from 1–500 mm/min).

- Step 3: The high-precision load cell detects the force required to break the ampoule neck.

- Step 4: The breaking force is recorded, and results are displayed on the HMI touch screen or printed via the integrated microprinter.

This process ensures the breaking force of ampoules is accurately measured according to industry standards.

Technical Features of the BST-01 Ampoule Breaking Strength Tester

The BST-01 Ampoule Breaking Strength Tester is equipped with a range of advanced features that enhance its accuracy and versatility:

- High-Precision Load Cell: Ensures reliable and precise force measurements with a resolution of 0.1N.

- Multiple Fixture Options: Test fixtures for 1ml, 2ml, 5ml, 10ml, and 20ml ampoules allow the tester to accommodate various ampoule sizes.

- Adjustable Test Speed: The test speed is adjustable between 1 and 500 mm/min, catering to different testing requirements.

- PLC Control and HMI Touch Screen: For easy operation and automation of the testing process.

- Stepper Motor with Precision Ball-Lead Screw: Provides accurate speed control for precise testing.

- Safety Features: Includes a protective cover to prevent sample jump, a collection tube for broken ampoule samples, and automatic return functionality.

- Optional Connectivity: RS 232 connectivity for integration with professional software and systems.

Other Relevant Standards and Compliance

In addition to ISO 9187, the BST-01 Ampoule Break Force Tester complies with several other industry standards, including:

- GB 2637: A Chinese national standard for ampoule testing.

- YBB00332002: A Chinese standard for ampoules used in pharmaceutical packaging.

These standards ensure the device’s versatility and compliance with global testing requirements.

Main Parameters of the Ampoule Break Force Tester

| Test Range | 0~200N (Or as required) |

| Speed | 1~500mm/min |

| Resolution | 0.1N |

| Accuracy | 0.5% F.S. |

| Power | 110~ 220V 50/60Hz |

The BST-01 Ampoule Break Force Tester is a reliable, versatile, and highly accurate device designed to meet the rigorous testing requirements of the pharmaceutical and medical packaging industries. By adhering to international standards such as ISO 9187, the tester ensures that ampoules are safe to use and meet the necessary breaking force specifications. With its advanced features, flexibility in testing different ampoule sizes, and ease of use, the BST-01 is an indispensable tool for manufacturers and quality control labs.

FAQ Section

- What is the purpose of an ampoule break force tester?

The tester measures the force required to break the neck of an ampoule, ensuring its strength and safety during handling and use. - How does ISO 9187 relate to ampoule testing?

ISO 9187 outlines the method and guidelines for testing the breaking force of ampoules, ensuring consistency and reliability in the testing process. - What are the key technical features of the BST-01 Ampoule Break Force Tester?

The tester features a high-precision load cell, multiple fixture sizes, adjustable test speeds, PLC control, and safety features such as protective covers and collection tubes. - Can the BST-01 be used to test other materials besides ampoules?

Yes, the BST-01 is versatile and can test other medical packaging materials such as syringes, caps, and stoppers. - What is the accuracy of the BST-01 Ampoule Break Force Tester?

The tester offers an accuracy of 0.5% full scale (F.S.), providing precise and reliable test results.