Penetration testing for elastomeric closures plays a critical role in ensuring the safety and reliability of pharmaceutical and medical packaging. Elastomeric closures, commonly used as rubber stoppers for vials and other medical devices, require stringent testing to meet industry standards such as ISO 8871-5 and USP 381. These standards ensure that closures can maintain the sterility and integrity of medical products, especially when subjected to penetration by needles or other devices.

The Importance of Elastomeric Closure Testing in the Pharmaceutical Industry

In the pharmaceutical industry, maintaining the integrity of packaging is essential to prevent contamination and ensure drug efficacy. Elastomeric closures are designed to seal medical containers securely, preventing the ingress of air or microorganisms. However, they also need to be penetrable by needles for administering medications. Penetration testing helps measure the resistance of these closures to ensure that needles can pierce them effectively without causing fragmentation or compromising the product.

Understanding ISO 8871-5 and USP 381 Standards

Both ISO 8871-5 and USP 381 are key standards that guide the testing of elastomeric closures.

- ISO 8871-5 focuses on determining the mechanical properties of closures used for parenteral drug containers, specifying the requirements for closure systems to ensure consistent performance under different conditions.

- USP 381 provides guidelines for the functionality and safety of elastomeric materials used in pharmaceutical containers. It outlines testing procedures to ensure closures are safe, do not introduce contaminants, and maintain proper sealing integrity when punctured by needles.

These standards ensure that penetration testing is conducted accurately and consistently, providing manufacturers with a reliable way to assess the performance of their products.

How Penetration Testing Works

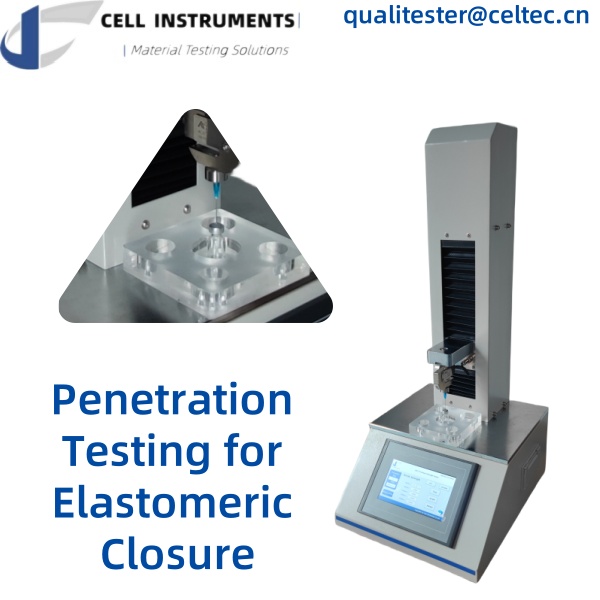

Penetration testing for elastomeric closures typically involves using a specialized instrument like the NPT-01 Needle Puncture Tester from Cell Instruments. This device is equipped with multiple needle types and jigs to accommodate different sample sizes and materials. The test involves measuring the force required for a needle to pierce the elastomeric closure, providing data on puncture resistance and material integrity.

The testing procedure follows a standardized process:

- A needle is mounted onto the device’s load cell.

- The elastomeric closure is secured in a fixed jig.

- The needle is driven at a controlled speed until it punctures the closure.

- The force exerted during the puncture is recorded to evaluate the closure’s performance.

This data helps manufacturers ensure that their closures are both resistant enough to maintain a secure seal and sufficiently penetrable for safe medical use.

Why Proper Penetration Testing is Critical

Accurate penetration testing is crucial for several reasons:

- Patient Safety: Ensuring that closures are properly punctured without introducing contaminants is vital in preventing patient exposure to harmful microorganisms.

- Product Integrity: Testing guarantees that closures maintain their protective properties after being punctured.

- Regulatory Compliance: Following ISO 8871-5 and USP 381 guidelines ensures that products meet international safety standards, avoiding costly recalls or regulatory penalties.

The Role of Cell Instruments’ NPT-01 Needle Puncture Tester

The NPT-01 Needle Puncture Tester from Cell Instruments is designed specifically for penetration testing of elastomeric closures. This versatile instrument allows users to test various closure materials under different conditions, offering flexibility in needle sizes and test speeds. Its precision ball screw mechanism and advanced control system ensure consistent and repeatable results, making it an ideal choice for pharmaceutical manufacturers.

By complying with both ISO 8871-5 and USP 381 standards, the NPT-01 ensures that elastomeric closures meet the necessary safety and performance requirements.

Penetration testing for elastomeric closures is essential for maintaining the safety and effectiveness of medical packaging. By following ISO 8871-5 and USP 381 standards and using advanced testing instruments like the NPT-01 Needle Puncture Tester, manufacturers can ensure their products are reliable and compliant with international regulations.

FAQ

1. Why is penetration testing important for elastomeric closures?

Penetration testing ensures that elastomeric closures can be safely punctured by needles without compromising the container’s sterility or integrity, crucial for medical and pharmaceutical applications.

2. What standards govern penetration testing for elastomeric closures?

ISO 8871-5 and USP 381 provide guidelines for the mechanical properties, functionality, and safety of elastomeric closures used in medical packaging.

3. How does the NPT-01 Needle Puncture Tester work?

The NPT-01 uses various needle types and test speeds to measure the puncture force needed to penetrate elastomeric closures, ensuring reliable and accurate testing results.

4. Can penetration testing detect defects in elastomeric closures?

Yes, penetration testing helps identify weaknesses in elastomeric closures, such as insufficient puncture resistance or the potential for fragmentation, ensuring product quality and safety.

5. What industries benefit from penetration testing of elastomeric closures?

The pharmaceutical, medical device, and packaging industries all benefit from penetration testing, ensuring that closures meet safety and performance standards.

Related Products

NPT-01 Penetration Testing Machine