포장 필름은 스트레치 필름이라고도 하며, 새로운 유형의 산업용 포장 필름 제품입니다. 가볍고 부드럽고 얇으며, 인장 특성, 신장 특성 및 자체 접착 특성이 특징입니다. 운송 포장에 적용하면 포장 효율성을 개선하고 비용을 절감하는 포장 방법입니다. 포장 스트레치 필름의 생산 품질을 보장하기 위해 제조업체는 특정 표준에 따라 생산해야 합니다.

CELL INSTRUMENTS에서는 스트레치 필름 테스트용 테스터를 아래와 같이 소개했습니다.

1. 두께 측정

100mm 길이 방향으로 전체 샘플을 잘라내고 30분간 방치한 후 20개 지점을 측정합니다. 측정값은 0.001mm 단위까지 정확하며, 산술 평균값을 구합니다.

2. ASTM D882에 따른 인장력 및 파단신율

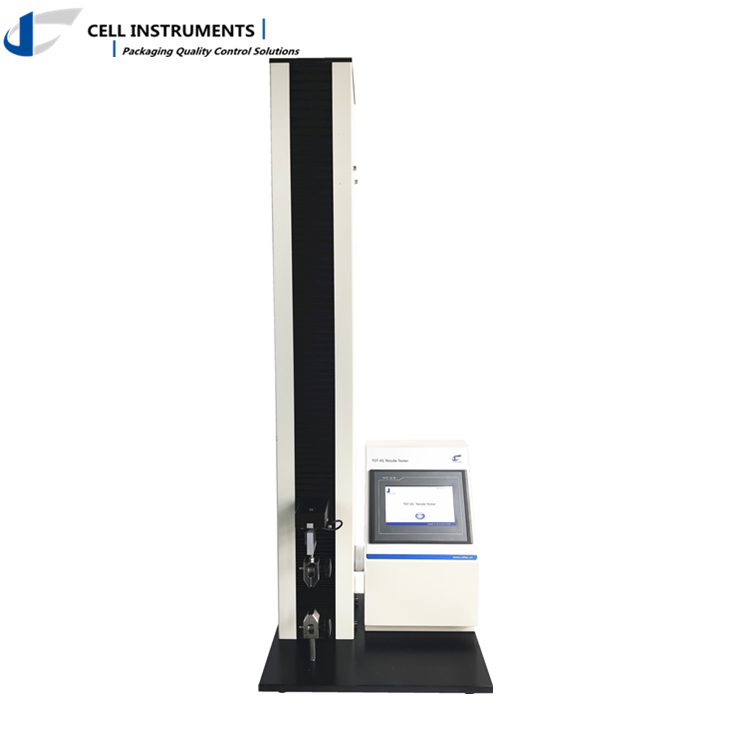

샘플은 15mm 폭으로 절단합니다. 샘플은 롤을 1m 풀고 나서 절단해야 하며, 샘플의 길이 또는 폭을 따라 대략 동일한 간격으로 균등하게 절단해야 합니다. TST-01 인장 시험기 게이지 길이를 50mm로 설정하고, 시험 속도는 250mm/min±25mm/min입니다. 수직 및 수평 세트의 두 세트가 있으며, 각 샘플 세트는 5개 이상이어야 하며, 산술 평균값을 취해야 하며 정확도는 0.1N입니다.

인장 시험기 TST-01

3. ASTM D5458에 따른 필링력 테스트

시험 샘플을 1m 펼친 후 샘플링을 시작하고, 샘플을 500mm×125mm(수직×수평) 및 180mm×25mm(수직×수평)의 두 그룹으로 나눕니다. 표준에 명시된 방법에 따라 샘플을 성공적으로 클램핑한 후, 두 샘플이 분리될 때까지 125mm/min±12.5mm/min의 속도로 클램프를 당기고, 분리 과정 중 최대 힘 값을 기록하며, 판독값은 0.1N까지 정확합니다.

4. ASTM D5748에 따른 돌출부 관통 저항성 시험

ASTM D5748 돌출 관통 저항성 시험은 특정 시험 영역을 갖춘 특수 프로브와 샘플 클램프를 사용하여 CELTEC TST-01 인장 시험기에서 실시됩니다.

필요한 샘플 클램프에 샘플을 고정합니다. 테스터를 시작하고 250mm/min±12.5mm/min의 속도로 펀처 바늘을 테스트하고 펀처 프로브가 필름을 완전히 통과하면 테스트가 중단됩니다. 필름이 다른 위치에서 끊어지면 샘플을 폐기해야 합니다. 샘플이 파열될 때의 파열력(N)과 신장(mm)을 기록합니다.