애플리케이션

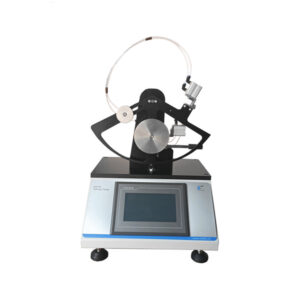

직각도 시험기는 병 편차 시험기, 동축 시험기, 동축도 또는 원형 런아웃 시험기(바이알 등)라고도 합니다.

동축 테스터는 식품, 화장품 및 제약 산업에서 다양한 병 용기의 수직도 측정을 위한 것입니다. 동축 테스터는 높은 센터링 및 측정 정밀도로 쉽게 작동하며 수직 편차를 위해 병 제조업체, 사용자 및 연구 시설에서 널리 사용됩니다.

작동 메커니즘

병은 회전판에 고정되어 있고 병 입구는 다이얼 게이지와 접촉합니다. 360°를 완전히 돌린 후 최대 및 최소 판독값을 기록합니다. 두 값의 차이의 1/2이 수직축 편차 값입니다.

기술 데이터

샘플 직경 5mm-145mm(또는 필요에 따라)

테스트 범위 0-12.7mm(또는 필요에 따라)

구분값 0.01 또는 0.001mm(선택사항)

측정 가능 높이 15mm-300mm(또는 필요에 따라)

기술적 특징

- 측정 프로브의 쉬운 조정.

- 최대 0.001mm의 높은 판독 분해능

- 샘플의 안정적인 회전

- 직경과 높이의 측정은 샘플 요구사항을 준수합니다.

- PC Excel로 데이터를 출력하는 것은 옵션입니다