소개

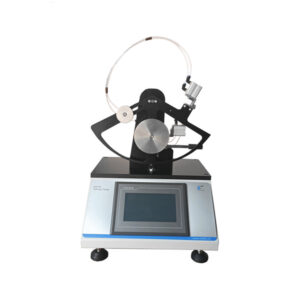

The Paper Softness Tester is a precision instrument designed to measure the softness of materials such as tissue, non-woven fabrics, and other soft packaging materials. This device plays a critical role in quality control by providing accurate data on the softness and flexibility of various materials, which are essential factors in industries like packaging, medical devices, textiles, and daily consumer goods. Equipped with advanced automation and electronic measurement technology, the Paper Softness Tester ensures fast, reliable, and repeatable results, helping manufacturers uphold product standards and meet consumer expectations.

Working Principle

The Paper Softness Tester operates based on a blade and slot mechanism. During testing, a sample is positioned across a slot on the testing platform, where a blade (probe) applies force to push the material into the slot. This force, measured by the tester, indicates the softness level of the sample, as it represents the sample’s resistance to bending or its flexibility. The tester’s design ensures precision by minimizing user interference, making it a trusted choice for laboratories and production lines alike.

적용 분야

The Paper Softness Tester is essential for evaluating the physical properties of products in various industries:

- 포장재: Ensures that packaging materials like soft tissue paper, thin plastic films, and cardboard meet softness and flexibility requirements.

- Paper Products: Ideal for testing tissue paper, toilet paper, and other consumer paper products to ensure optimal softness.

- 의료 및 제약: Suitable for materials like medical-grade papers and non-wovens, which need specific softness for functionality and comfort.

- 섬유 및 접착제: Assesses the softness and flexibility of textiles and adhesives, ensuring they meet industry standards for comfort and usability.

This versatility makes the tester indispensable in sectors like packaging, food, pharmaceuticals, textiles, and quality inspection agencies.

Key Standards

The Paper Softness Tester is fully compliant with the following ASTM standards, providing standardized testing methods and reliable results:

- GB/T 8942 Paper-Determination of Softness

- ASTM D2923 Test Method for Rigidity of Polyolefin Film and Sheeting

- QB/T 1060 Softness Tester

- 타피 T498 Softness of Sanitary Tissues

- ASTM D6828−02 (Reapproved 2019) Standard Test Method for Stiffness of Fabric by Blade/Slot Procedure

Adherence to these ASTM standards guarantees that the Paper Softness Tester meets international testing requirements, offering users confidence in the quality and accuracy of their results.

Benefits of the Paper Softness Tester

- Automated, Accurate Measurements: The tester’s automated design minimizes the chance of human error, providing consistently precise results without manual adjustments.

- 사용자 친화적인 작동: With a straightforward sample placement and automatic testing procedure, operators can easily conduct tests without extensive training.

- Enhanced Reliability: The electronic control system provides highly repeatable results, ensuring consistency in quality control assessments.

기술 사양

| 테스트 범위 | (10~1000) mN |

| Test Blade Size | R. mm, 120mm*2mm L*D |

| Blade Stroke | 8±0.5mm |

| 테스트 속도 | 1.2mm/s |

| Force Resolution | 1mN |

| 정확성 | ±1% |

| Slot Width | 5mm, 6.35mm, 10mm, 20mm |

| 힘 | 교류 220V 50Hz |

Why Choose Our Paper Softness Tester?

Our Paper Softness Tester stands out for its durability, precision, and adherence to ASTM standards (ASTM D2063, ASTM D3198, and ASTM D3474). This tester is ideal for quality assurance in industries that prioritize material softness, such as packaging, consumer goods, and healthcare. Additionally, customization options are available to meet specialized testing requirements, ensuring this instrument meets the unique needs of each user.

자주 묻는 질문(FAQ)

1. How does the Paper Softness Tester differ from other softness testing methods?

Unlike manual testers, this automated tester minimizes user bias and improves accuracy by electronically measuring the force needed to penetrate the sample.

2. What types of materials can be tested with this instrument?

This tester is suitable for soft materials like tissue paper, non-wovens, fabrics, and some packaging materials, providing flexibility in application.

3. How accurate are the results, and are they repeatable?

The electronic control system ensures high accuracy and repeatability, making this tester highly reliable for quality control.

4. Is the Paper Softness Tester easy to use for non-technical staff?

Yes, the automated testing process and straightforward sample placement make it user-friendly, even for operators with minimal technical experience.