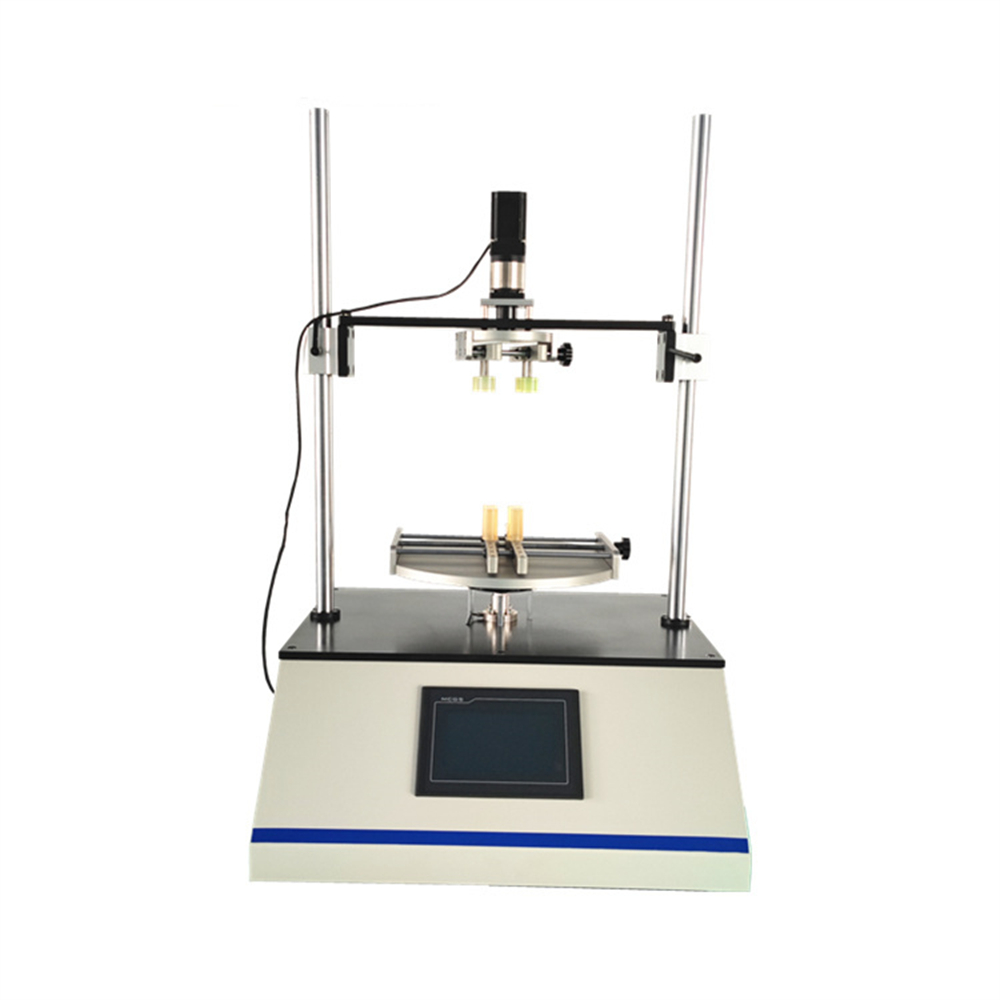

자동 토크 테스터 소개

그만큼 자동 토크 테스터 약품 병, PET 병, 주둥이 봉지, 유연한 튜브를 포함한 다양한 용기의 캡의 개방 및 잠금력을 평가하는 데 필수적인 도구입니다. 이 테스터는 소비자가 쉽게 여는 동시에 캡이 안전하게 밀봉되도록 하여 제품 안전, 품질 및 사용성을 최적화합니다. 고급 자동화 및 정밀성을 갖춘 Automated Torque Tester는 포장, 제약, 식품 및 음료, 화장품과 같은 산업의 품질 관리에서 중요한 역할을 합니다.

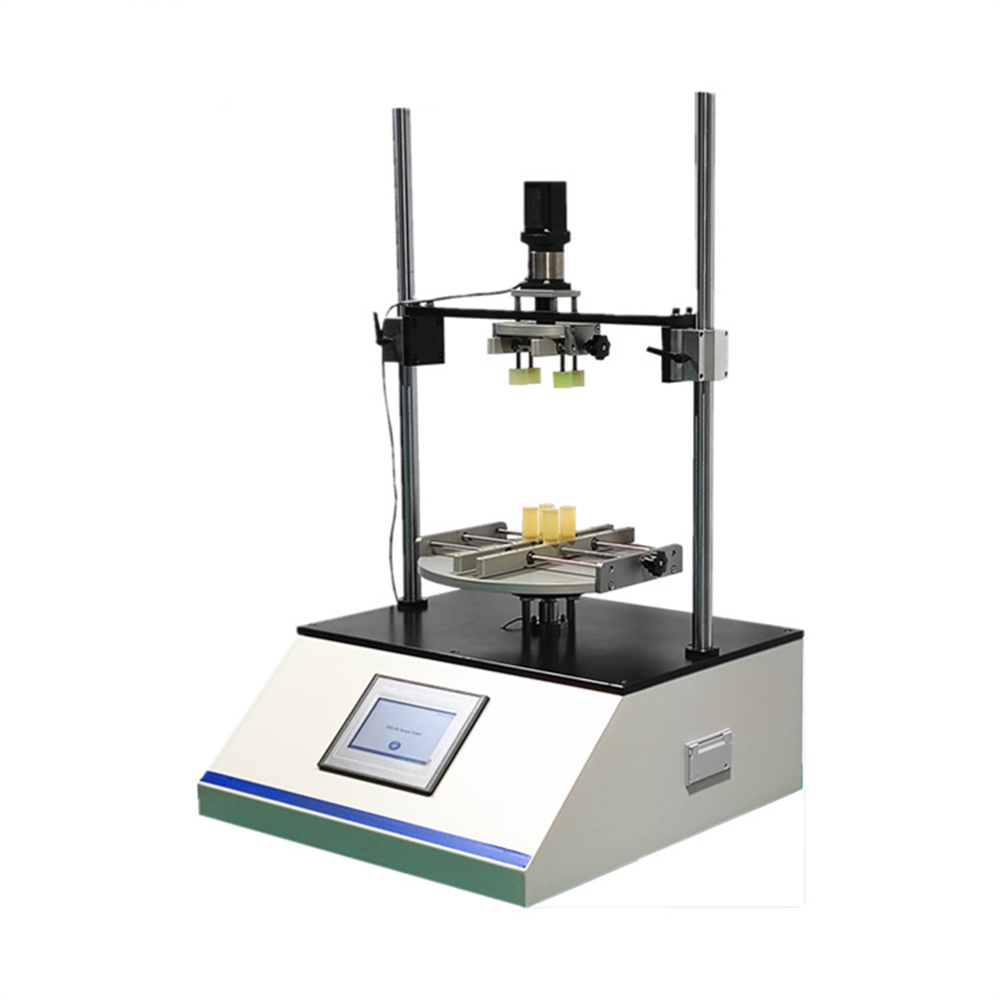

자동 토크 테스터의 주요 응용 분야

자동 토크 테스터는 다음 분야에 널리 적용 가능합니다.

- 포장: 운송 중에는 뚜껑이 밀봉 상태를 유지하면서도 소비자가 쉽게 열 수 있는지 확인합니다.

- 제약품: 안전 기준을 충족하기 위해 아동용 잠금식 뚜껑과 훼손 방지 잠금장치를 테스트합니다.

- 음식과 음료: PET 및 기타 유형의 병의 뚜껑 무결성을 확인하여 누출 및 오염을 방지합니다.

- 화장품 및 일상화학제품: 제품의 수명과 사용 편의성을 향상시키기 위해 캡 잠금 강도를 테스트합니다.

병 뚜껑 토크 테스트 관련 표준

그만큼 자동 토크 테스터 여러 가지 중요한 산업 표준을 준수하여 다양한 포장 부문에서 포괄적인 테스트와 규정 준수를 보장합니다. 다음 표준은 테스트 프로세스에 필수적입니다.

- ASTM D2063: 이 표준은 플라스틱 클로저의 개폐 토크 측정, 특히 포장 응용 분야에 초점을 맞춥니다. 안전하지만 쉽게 열 수 있는 캡에 필요한 토크 값을 결정하여 소비자 편의성과 안전성을 모두 보장하는 데 필수적입니다.

- ASTM D3198: 이 표준은 아동용 잠금장치의 토크 측정을 위한 테스트 방법을 명시합니다. 변조 방지 포장을 평가하고 잠금장치가 제약, 화학 물질 및 기타 민감한 제품에 대한 규제 안전 표준을 충족하는지 확인하는 데 중요합니다.

- ASTM D3474: 이 표준은 주둥이 파우치와 같은 유연한 용기의 폐쇄 토크 테스트를 다룹니다. 이는 개방 및 밀봉 조건에서 폐쇄의 성능을 보장하여 공급망 전체에서 제품 무결성을 유지합니다.

- 영국/태국 17876: 병과 용기의 잠금 토크를 테스트하기 위한 지침을 제공하는 중국 표준입니다. 다양한 조건에서 포장 잠금 강도와 신뢰성을 측정하기 위한 국제적 관행과 일치합니다.

- 비비티 0025: 이 중국 표준은 다양한 밀봉 및 개방 조건에서 용기 마개의 성능을 평가하는 방법을 지정하여, 뚜껑이 안전하고 사용자 친화적인지 확인합니다.

- 비비티 0034: 개봉 흔적 방지 잠금장치의 토크 저항성에 초점을 맞춘 또 다른 중국 표준으로, 이 표준은 포장이 제품 무결성과 소비자 보호에 대한 안전 및 규제 요구 사항을 충족하는지 확인합니다.

자동 토크 테스터의 테스트 프로세스

자동 토크 테스터는 정확하고 반복 가능한 결과를 위한 간단하고 자동화된 프로세스를 제공합니다.

- 시편 로딩: 샘플 병이나 용기를 시스템에 위치시키고, 캡과 병은 모두 공압 클램프로 단단히 고정합니다.

- 클램핑: CLAMP 버튼을 누르면 공압 클램프가 자동으로 맞물려 테스트를 위해 캡과 병이 제자리에 고정됩니다.

- 테스트: TEST 버튼을 누르면 하단 클램프가 회전하여 테스트 요구 사항에 따라 캡이 열리거나 닫힙니다.

- 토크 측정: 회전하는 동안 시스템은 토크 힘 데이터를 정확하게 기록하여 최대 값과 평균 값에 대한 통찰력을 제공합니다.

이 프로세스를 통해 캡의 성능을 빠르게 분석하여 밀봉 또는 개방 시 적용되는 토크가 품질 및 사용성 측면에서 제품 사양과 일치하는지 확인할 수 있습니다.

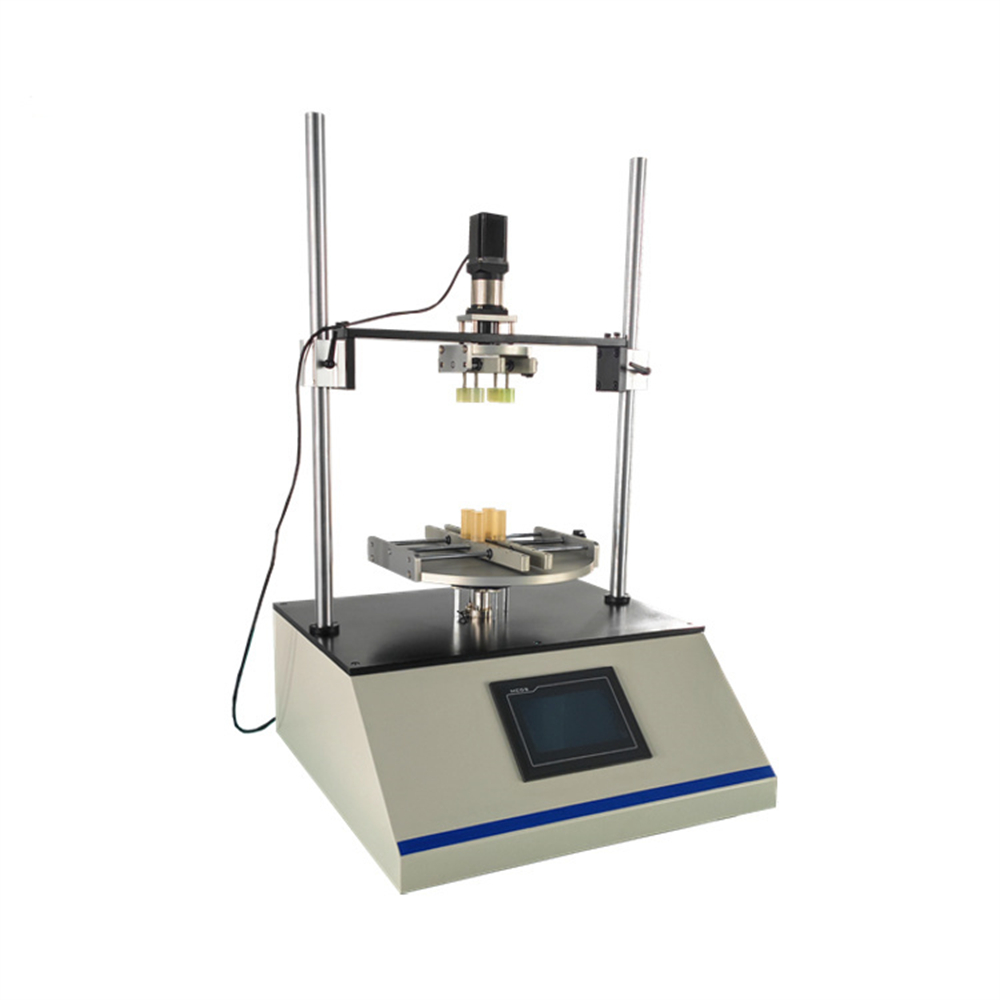

기술적 특징 및 이점

자동 토크 테스터의 고성능 기능은 품질 관리를 위한 신뢰할 수 있는 솔루션을 제공합니다.

- HMI 터치스크린을 사용한 PLC 제어 작업: 사용자 친화적인 인터페이스를 갖춘 이 테스터는 반복 가능한 정확성과 일관된 결과를 보장하므로 처리량이 많은 환경에 이상적입니다.

- 자동 클램핑 및 회전: 생산 조건을 시뮬레이션하는 테스터의 자동 클램핑 및 회전 기능은 캡 성능을 현실적으로 평가합니다.

- 다중 단위 측정 디스플레이: 다양한 단위(Kgf.cm, N.cm, daN.cm, Inch.lbs, Nm)로 데이터를 볼 수 있어 국제 표준을 준수하고 다양한 산업에 적용할 수 있습니다.

- 피크 값 유지 및 데이터 로깅: 테스터는 종합 분석을 위해 자동으로 피크 토크 값을 보관하고 빠른 데이터 액세스를 위한 온보드 마이크로 프린터를 포함합니다. 선택 사양인 RS232 연결 및 전문 소프트웨어도 디지털 데이터 관리를 허용합니다.

- 안전성과 효율성: 과부하 보호 기능과 자동 제로화 기능이 내장되어 있어 안전성과 측정 정확도가 모두 향상되어 이 테스터는 엄격한 품질 보증 분야에 적합합니다.

산업 표준 및 규정 준수

자동 토크 테스터는 다음을 포함한 여러 핵심 표준의 요구 사항을 충족하도록 설계되었습니다. ASTM D2659, ASTM D4577, ASTM D642, ISO 8113, 그리고 ASTM D4169. 이러한 표준을 따르면 제품이 엄격한 품질 및 안전 요구 사항을 충족하는 것이 보장되어 포장 규정 준수를 요구하는 산업에 신뢰할 수 있는 테스트 솔루션을 제공합니다.

자주 묻는 질문 섹션

- 포장에 토크 테스트가 중요한 이유는 무엇입니까?

토크 테스트를 통해 캡이 안전하게 밀봉되어 있고 사용하기 편리한지 확인하며, 안전 및 소비자 사용성 기준을 모두 충족합니다. - 수동 토크 테스터에 비해 자동 토크 테스터를 사용하는 이점은 무엇입니까?

자동화 테스터는 특히 대량 생산 환경에서 더 높은 정확성, 반복성, 효율성을 제공합니다. - 테스터는 ASTM D2659 준수 여부를 어떻게 보장합니까?

테스터는 토크를 정확하게 측정하여 ASTM D2659 아동 보호 및 훼손 방지 잠금 장치 표준을 충족하는 데 도움이 됩니다. - 토크 테스터는 다양한 캡 크기와 재질을 수용할 수 있나요?

네, 테스터는 다양한 캡 유형 및 소재와 호환되므로 제품 전반에 걸쳐 다양한 테스트가 가능합니다. - 피크 값 유지 기능은 어떻게 작동하나요?

테스터는 각 테스트 동안 도달한 최대 토크 값을 포착하여 유지하므로 자세한 분석과 품질 보증이 가능합니다.

그만큼 자동 토크 테스터 제품 품질, 안전 및 규정 준수를 보장하려는 제조업체에 필수적인 도구입니다. 자동화된 기능을 통해 다음과 같은 국제 표준을 준수합니다. ASTM D2659, 신뢰할 수 있는 정밀도를 갖춘 이 테스터는 제품 무결성에 대한 뛰어난 표준을 유지하는 동시에 생산 공정을 간소화하는 데 도움이 됩니다.