소개

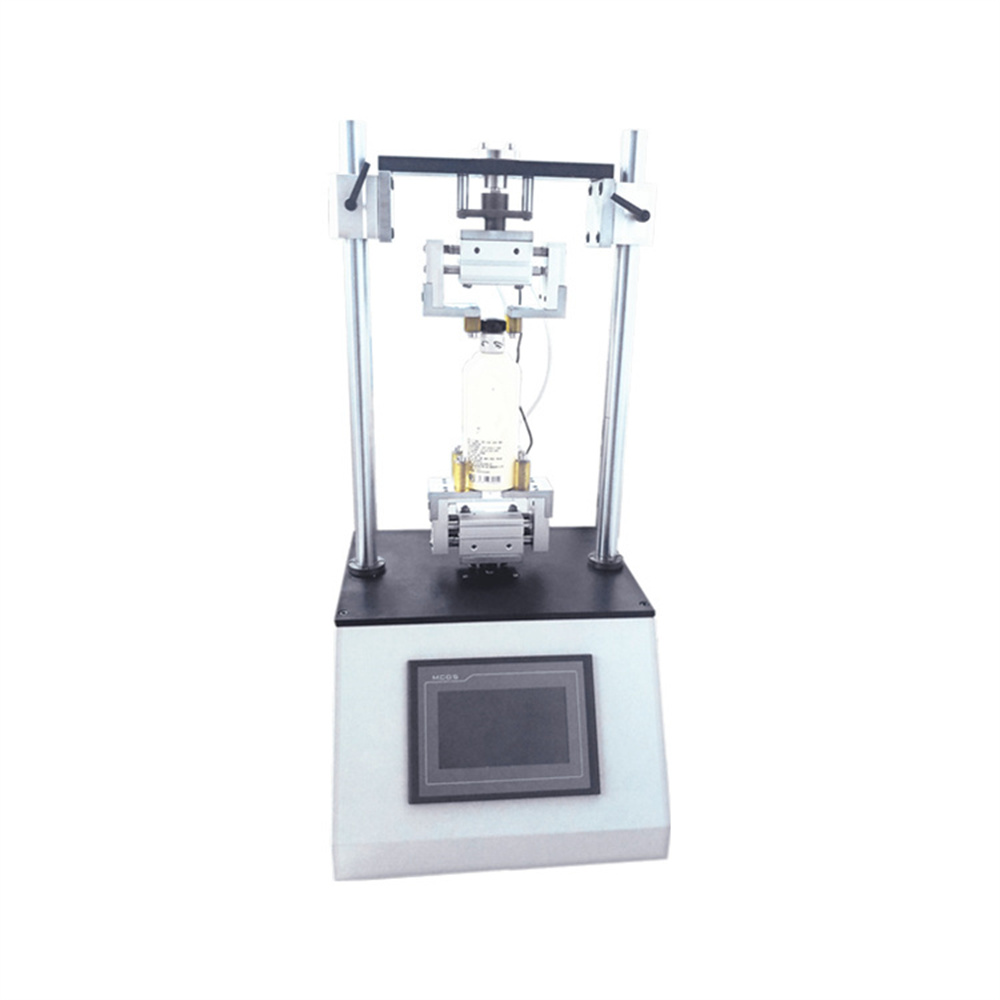

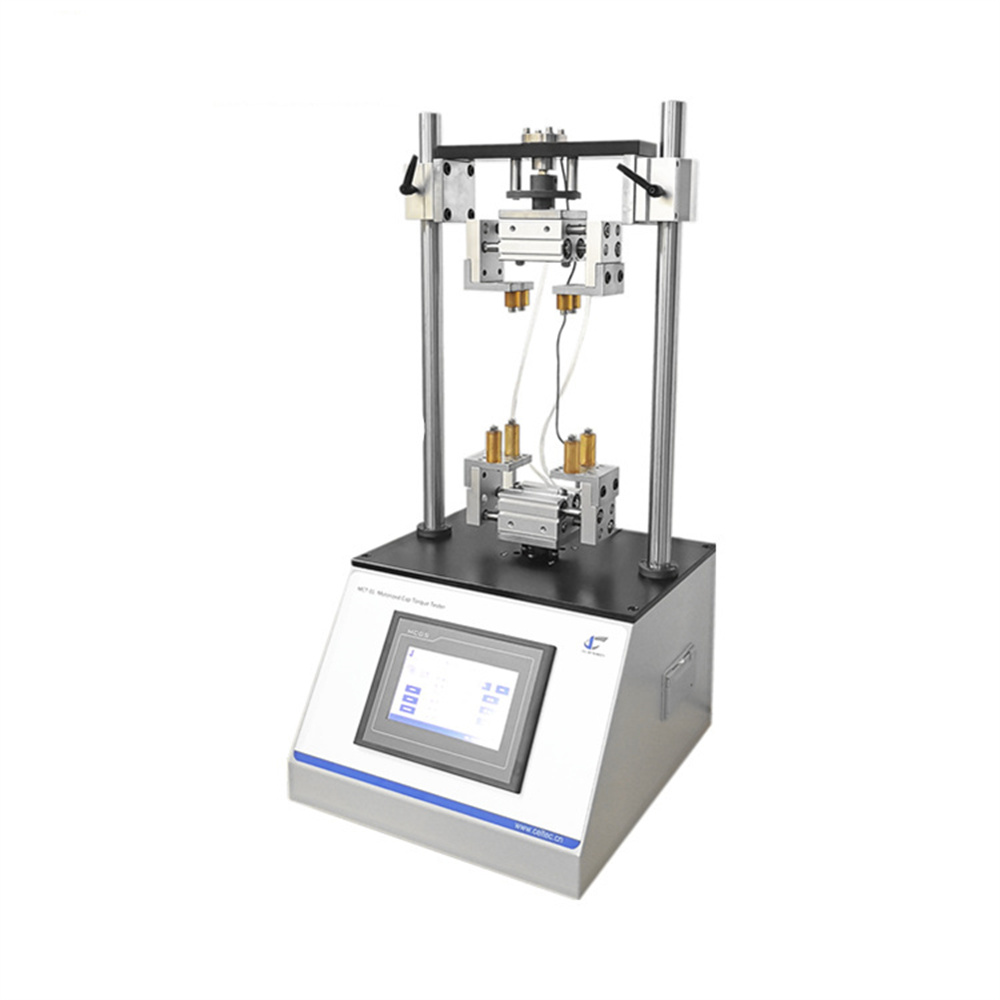

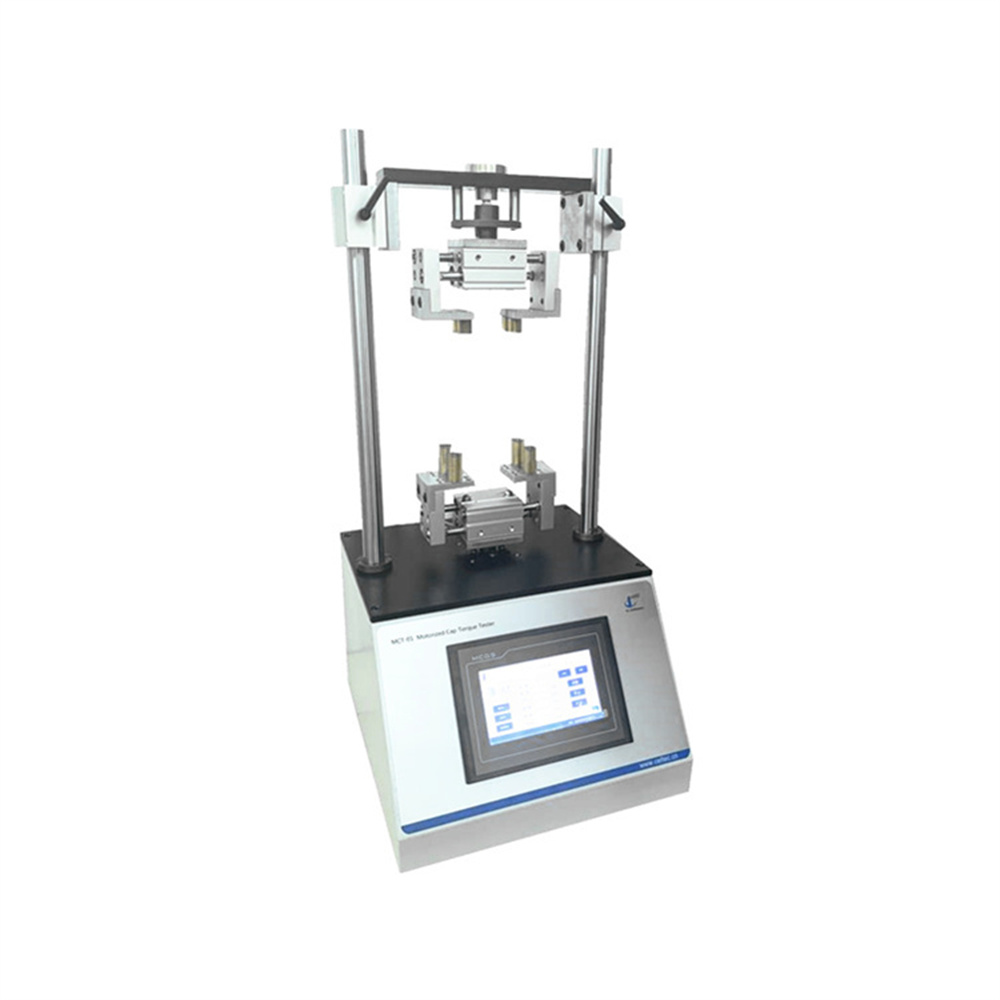

그만큼 Automatic Cap Torque Tester (MCT-01) is a highly precise and efficient instrument designed to measure the open and lock forces of caps on various types of containers. This testing is critical in packaging applications across industries such as pharmaceuticals, food and beverages, medical devices, and consumer products. Proper torque measurements ensure that caps are securely sealed for transportation, yet easy for consumers to open, offering both safety and convenience. With its advanced technology, the MCT-01 provides reliable and accurate torque measurements that are essential for quality control and compliance with industry standards.

적용 분야

그만큼 Automatic Cap Torque Tester is widely used in several sectors, including:

- 포장 산업: Ensures that containers such as PET bottles, spout bags, medicine bottles, and flexible tube packages meet the necessary sealing and opening force requirements.

- Pharmaceutical & Medical Devices: Assures that drug containers are sealed effectively, reducing the risk of contamination or tampering.

- Food & Beverage: Verifies the torque of bottle caps to ensure ease of opening while maintaining product integrity.

- 소비재: Helps to test cap functionality for various consumer packaging, ensuring the right balance between seal strength and user convenience.

- Custom Testing Solutions: Cell Instruments also specializes in providing customized testing requirements to meet the unique needs of different industries.

테스트 프로세스

The test process with the Automatic Cap Torque Tester (MCT-01) is fully automated for ease of use:

- Specimen Loading: The bottle and cap are placed in the tester, with both the bottle pneumatic clamp and the cap pneumatic clamp automatically engaging to secure the specimen.

- Test Initiation: By pressing the TEST button, the lower clamp initiates rotation, either opening or closing the bottle depending on the test requirements.

- 토크 측정: During the rotation, the torque force is precisely measured and recorded in real-time. The system automatically retains the peak torque values for both opening and locking forces.

- 데이터 분석: The measured torque data is displayed in multiple units, including Kgf.cm, N.cm, daN.cm, Inch.lbs, and N.m, allowing for comprehensive analysis and quality control.

기술적 특징

- PLC 제어 장치: For industrial-level stability, the tester operates with a PLC-controlled unit and an intuitive HMI touchscreen interface.

- Dual Pneumatic Clamping: The upper and lower pneumatic clamps ensure secure testing without damaging the bottle or cap.

- Automatic Rotation & Torque Measurement: Simulates real-world production conditions with automatic rotation, making the system ideal for quality assurance.

- Multi-Unit Measurement: Displays torque in Kgf.cm, N.cm, daN.cm, Inch.lbs, and N.m for flexible analysis.

- Overload Protection & Auto-Zeroing: The system includes overload protection to ensure reliable, consistent measurements and an auto-zeroing function for accurate readings.

- RS232 Port & Software: Optionally available with an RS232 port and professional computer software for detailed reporting and data management.

- 마이크로 프린터: Provides instant printouts for quick reference during production and testing.

주요 표준

그만큼 Automatic Cap Torque Tester (MCT-01) complies with industry standards, ensuring that it meets rigorous quality assurance requirements:

- ASTM D2063: Standard Test Method for the Torque (Force) of Closure Systems for Aseptically Packed Containers

ASTM D2063 outlines the method for determining the torque needed to open and close aseptic closure systems, which is particularly critical in pharmaceutical and food packaging. This standard ensures that the torque is sufficient to provide an airtight seal while allowing for easy opening by the consumer. - ASTM D3198: Standard Test Method for Measuring the Torque (Force) of Closure Systems for Bottles and Containers

ASTM D3198 provides guidelines for testing the torque force of caps and closure systems on containers such as bottles and jars. It focuses on ensuring that caps are properly sealed during manufacturing and can be securely opened by consumers. - ASTM D3474: Standard Test Method for Determining the Torque (Force) of Closures on Containers

ASTM D3474 defines a method for testing closure torque on various containers, ensuring that caps are applied with the correct torque during production. This standard helps maintain consistent product performance and packaging safety. - 기타 관련 표준:

The MCT-01 also adheres to additional standards, such as GB/T17876, BB/T0025, 그리고 BB/T0034, which provide guidelines for packaging and closure testing in different markets and regions.

Benefits of Using the Automatic Cap Torque Tester

- 정밀도와 신뢰성: The MCT-01 delivers highly accurate and repeatable torque measurements, essential for ensuring the proper sealing of containers and consumer ease of use.

- 사용의 용이성: With an intuitive touch-screen interface and fully automated testing functions, the system is easy to operate, making it ideal for both new and experienced operators.

- 강화된 품질 관리: Helps manufacturers meet strict industry standards by accurately assessing cap torque forces, improving product quality, and ensuring consumer safety.

- 산업 표준 준수: The tester meets ASTM D2063, ASTM D3198, and ASTM D3474, providing peace of mind that products are in line with global quality assurance regulations.