Introduction to Pendulum Impact Testing

Impact resistance is a crucial property for materials subjected to sudden shocks or repetitive forces. When materials are exposed to such loads, they may experience rupture, cracking, or deformation. Pendulum impact testing is one of the most effective methods to evaluate this property, especially for thin films, sheets, composites, foils, and paper. This testing method allows for a quantitative measurement of the energy required to cause material failure.

The Pendulum Impact Tester provides a precise and repeatable means of measuring how well materials can withstand sudden impact forces. Impact resistance testing plays an essential role in ensuring that materials are reliable and durable for use in industries such as packaging, automotive, construction, and textiles. Choosing the appropriate impact test depends on the specific material and the type of impact load it is expected to endure.

ASTM D3420: Pendulum Impact Tester Standard

- Overview of ASTM D3420

The ASTM D3420 standard outlines the method for determining the impact resistance of materials using the pendulum impact tester. This standard is specifically used for testing films, foils, and thin sheets. By following this test, manufacturers can ensure that their materials meet the required impact resistance levels for their intended applications. - Test Methodology According to ASTM D3420

The pendulum impact test according to ASTM D3420 involves placing a specimen in a clamp and subjecting it to a swinging pendulum of defined energy. The pendulum impacts the material at a specific angle, and the energy required to rupture or penetrate the material is measured. The test is repeated with varying impact energies to assess the material’s durability across different impact scenarios. - Key Requirements and Standards Compliance

The ASTM D3420 standard specifies the use of specific specimen sizes (100×100 mm or Φ100 mm) and impact head diameters (Φ25.4 mm, Φ19 mm, Φ12.7 mm). Compliance with this standard ensures that test results are both reliable and reproducible, meeting the industry’s strict requirements for material impact resistance testing.

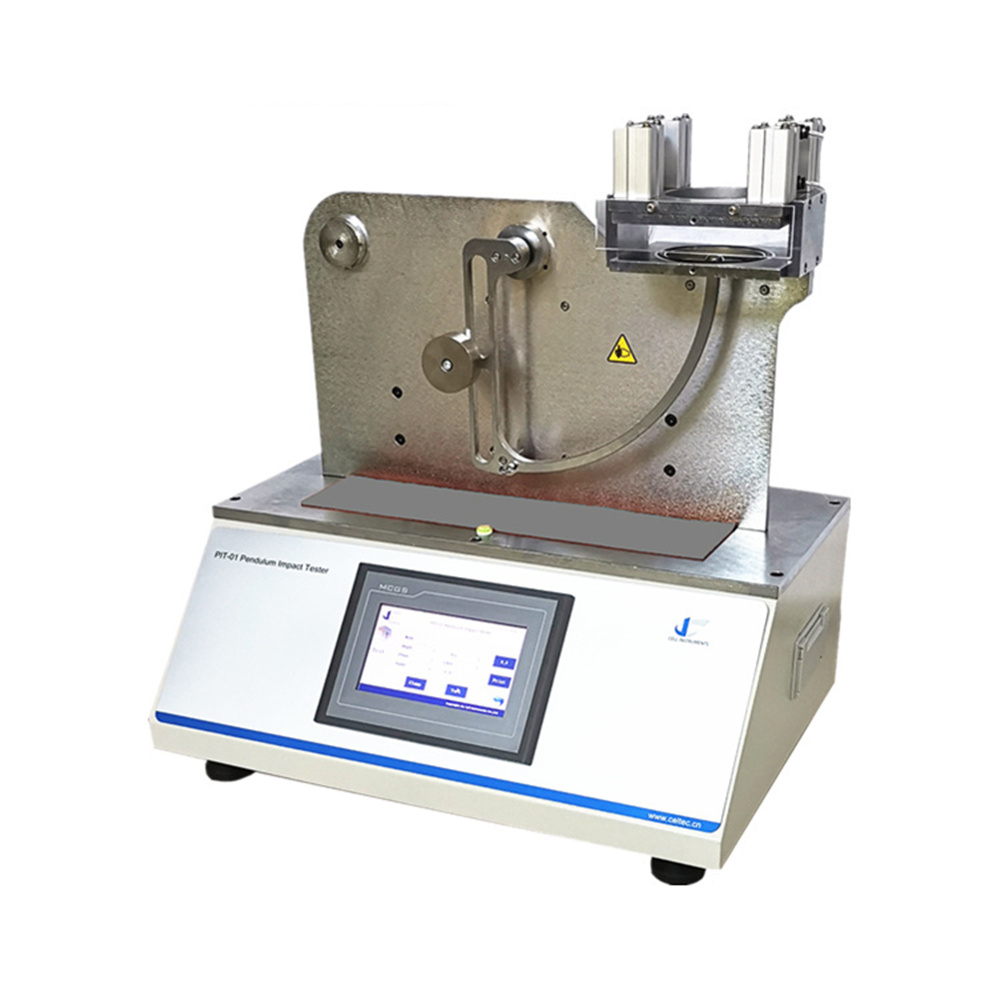

Features and Capabilities of the Pendulum Impact Tester (PIT-01)

- PLC Control & HMI Touchscreen

The Testeur d'impact à pendule PIT-01 is equipped with a PLC (Programmable Logic Controller) for precise control of testing parameters. The intuitive HMI (Human-Machine Interface) touchscreen allows operators to easily configure the test and monitor results, ensuring ease of use and operational efficiency. - Pneumatic Clamping Mechanism

To ensure consistent and reliable testing, the PIT-01 features pneumatic clamping. This mechanism securely holds the specimen in place during the test, eliminating variation that may arise from manual clamping. The result is highly repeatable and accurate data. - Automatic Pendulum Release and Precise Angle Measurement

The pendulum is automatically released, ensuring the testing process is seamless and precise. Additionally, the angle at which the pendulum strikes the specimen is precisely measured, providing accurate data on the energy absorbed by the material during the impact. - Data Auto-Statistics and Reporting

The PIT-01 includes a built-in data auto-statistics feature that automatically collects and processes test data. This eliminates the need for manual data entry and reduces the chance of human error. The test results are displayed on the screen and can be printed immediately using the built-in microprinter. An optional RS232 port allows for further analysis and storage of the test data. - Impact Head Size Variability

The PIT-01 offers flexibility with its impact head sizes, available in Φ25.4 mm, Φ19 mm, and Φ12.7 mm. This adaptability ensures the tester can be used for a wide range of materials, each requiring different test configurations.

Application Areas of the Pendulum Impact Tester

- Packaging Industry

The Pendulum Impact Tester is ideal for assessing the impact resistance of packaging materials, such as films, foils, and paper. Packaging materials need to withstand harsh conditions during transport, and impact testing helps ensure that these materials perform as required. - Automotive and Aerospace

In the automotive and aerospace industries, composite materials need to meet stringent impact resistance standards. The PIT-01 is a valuable tool for testing the durability of materials used in vehicle bodies, interior components, and aircraft structures. - Construction and Materials Engineering

Construction materials like plastic sheets, foils, and films often need to resist sudden impacts. The Pendulum Impact Tester ensures that these materials meet the required impact resistance standards for their application. - Other Key Industries

The PIT-01 also finds application in the food packaging industry, medical device packaging, textiles, and other sectors that rely on the integrity of thin materials exposed to impact forces.

Specifications of the PIT-01 Pendulum Impact Tester

| Impact Energy | 1 J, 2 J, 3 J |

| Resolution | 0.001 J |

| Impact Head Size | Ф25.4, Ф19, Ф12.7 mm |

| Specimen Clamp | Pneumatic Clamp |

| Clamp Diameter | Ф89 mm, Ф60 mm |

| Gas Supply | 0.6 MPa Φ6 mm PU Tubing |

| Specimen Size | 100*100 mm or Ф100 mm |

| Power Supply | AC 110~220V 50Hz |

Similar Models and Comparisons

- Falling Dart Impact Tester (FDT-01)

The Falling Dart Impact Tester (FDT-01) is another widely used impact testing device that uses a falling dart to measure material impact resistance. Unlike the pendulum method, the falling dart tester is designed to assess materials that are prone to puncturing under impact. - Falling Ball Impact Tester (FBT-01)

The Falling Ball Impact Tester (FBT-01) tests materials by dropping a steel ball onto the specimen from a set height. This method is often used for testing materials with a higher thickness or hardness. - Charpy and Izod Impact Testers

The Charpy and Izod Impact Testers are used to measure the impact toughness of materials, particularly metals and plastics. These methods use a different approach, with a notched specimen subjected to a swinging hammer, but are often compared with pendulum impact tests for certain applications.

The Testeur d'impact à pendule PIT-01 offers unparalleled accuracy and repeatability, making it the ideal tool for assessing the impact resistance of various materials. With its advanced features like PLC control, pneumatic clamping, automatic pendulum release, and precise angle measurement, it provides the most reliable results for your impact testing needs. Whether for packaging, automotive, construction, or other material testing applications, the PIT-01 ensures that your materials meet the highest performance standards.