Introduction

Dans l'industrie de l'emballage, le maintien de l'intégrité des joints est essentiel pour garantir la sécurité et la qualité des produits. Les équipements de test de résistance des joints sont conçus pour évaluer la capacité du joint à résister aux conditions environnementales, empêchant ainsi les fuites et la contamination. Ces tests sont essentiels pour les industries telles que l'emballage alimentaire, les produits pharmaceutiques, les dispositifs médicaux, les cosmétiques et bien d'autres, où les performances de l'emballage affectent directement la qualité du produit et la sécurité du consommateur.

Instruments cellulaires Équipement de test de résistance des joints fournit une méthode précise et fiable pour évaluer l’intégrité des joints, garantissant que les produits emballés restent sûrs, protégés et conformes aux normes de l’industrie.

Qu'est-ce qu'un équipement de test de résistance des joints ?

Les équipements de test de résistance des joints sont utilisés pour évaluer la résistance et la fiabilité des joints des matériaux d'emballage. L'équipement évalue si les joints de divers types d'emballages (plastique, papier, aluminium, etc.) sont suffisamment solides pour empêcher les fuites qui pourraient compromettre le produit. Ce test est couramment utilisé pour les matériaux d'emballage des produits alimentaires, pharmaceutiques, des dispositifs médicaux et des biens de consommation.

En utilisant une technologie de test avancée, le testeur de résistance des joints permet d'identifier les joints faibles ou défectueux avant qu'ils n'atteignent les consommateurs, garantissant ainsi une qualité de produit élevée et le respect des normes de sécurité.

Aperçu de la norme ASTM D3078 : normes de test d'intégrité des joints

Qu'est-ce que la norme ASTM D3078 ?

ASTM D3078 Il s'agit d'une méthode de test standard développée par ASTM International pour détecter les fuites dans les emballages scellés. Cette méthode applique un vide à l'emballage et surveille la présence de bulles indiquant des fuites, garantissant ainsi l'intégrité du joint. Ce test est particulièrement important pour les industries agroalimentaires et pharmaceutiques, où l'emballage doit conserver son intégrité pour éviter toute contamination ou détérioration.

Méthode d'essai selon la norme ASTM D3078

Le ASTM D3078 La norme décrit un procédé dans lequel l'emballage est placé dans une chambre remplie d'eau. La chambre est scellée et l'air est évacué jusqu'à ce que le niveau de vide prédéfini soit atteint. En cas de fuite, la différence de pression d'air force l'air emprisonné à s'échapper, formant des bulles visibles à l'endroit de la fuite. Cette méthode constitue un moyen efficace et fiable de détecter même les plus petites fuites.

Méthodes et paramètres de test clés

Processus de test

Le processus de test de résistance des joints suit une séquence simple décrite par la norme ASTM D3078 :

- Préparation des échantillons : L’échantillon est placé à l’intérieur d’une chambre transparente remplie d’eau.

- Application sous vide : L'unité de commande extrait l'air jusqu'à ce qu'un niveau de vide prédéfini soit atteint.

- Détection de fuite : Si une étanchéité est compromise, des bulles se formeront au point de fuite, indiquant la défaillance de l'emballage.

Principaux paramètres de test

| Plage de test | 0~-90 KPa |

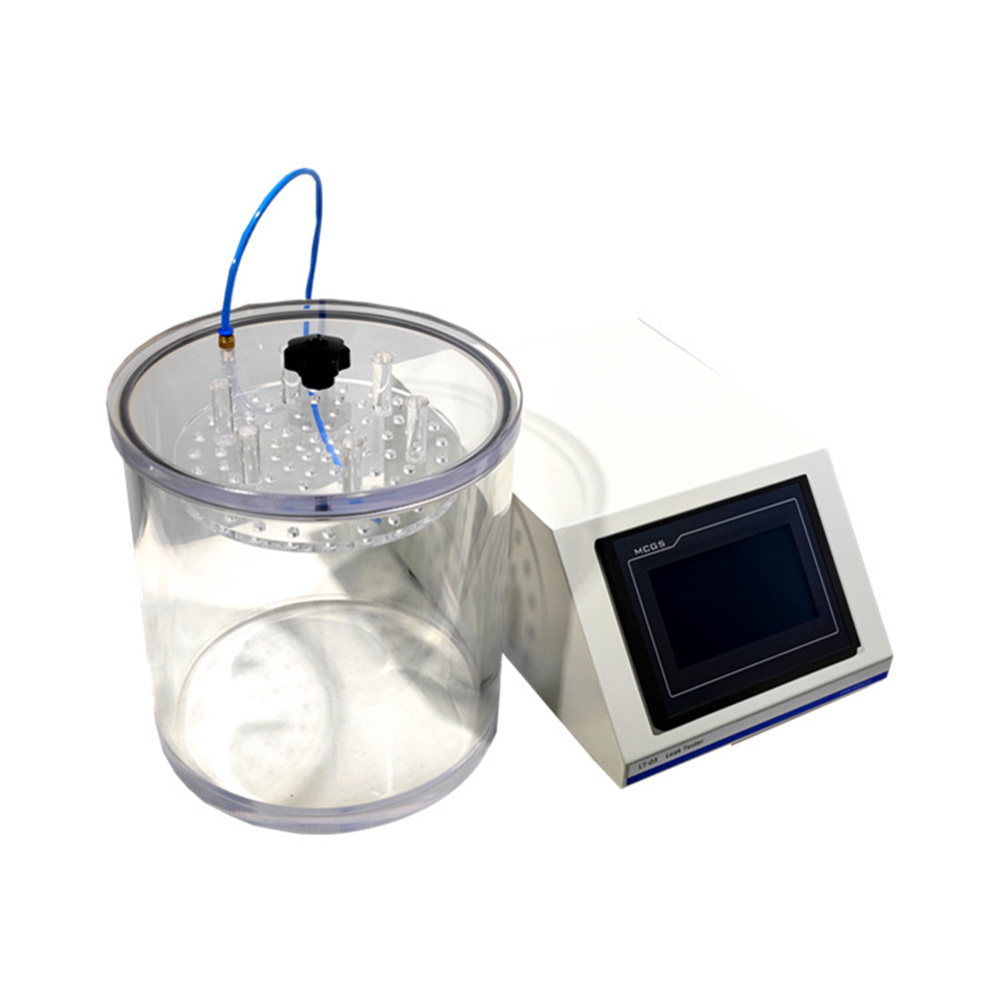

| Chambre | Forme de cylindre en acrylique |

| Espace de test | Φ270*H210mm (utilisable à l'intérieur) |

| Air comprimé | 0,7 MPa (préparé par l'utilisateur) |

| Pouvoir | 110~220V 50/60Hz |

Ces paramètres permettent à l'utilisateur de tester une variété de matériaux et de tailles d'emballage, garantissant ainsi une flexibilité dans différents environnements de production et de test.

Caractéristiques techniques de l'équipement de test de résistance des joints

Fonctionnement contrôlé par PLC

L'équipement est contrôlé par un PLC (automate programmable), ce qui garantit des résultats de test stables, répétables et de haute qualité. L'interface utilisateur est conçue avec un écran tactile IHM (interface homme-machine), offrant un contrôle intuitif et une facilité d'utilisation.

Système de vide efficace

L'unité de test utilise un Tube de Venturi pour générer un vide allant jusqu'à -90 KPa, ce qui en fait un système économe en énergie. Ce niveau de vide est suffisant pour identifier les fuites, même les plus petites, garantissant ainsi des tests de haute qualité sans nécessiter d'équipement supplémentaire.

Détection visuelle des fuites

Le test utilise une méthode d'observation visuelle pour détecter les fuites. En cas de fuite, l'air s'échappant de l'emballage forme des bulles visibles dans la chambre remplie d'eau, ce qui permet une identification rapide. L'équipement fournit des résultats cumulatifs, ce qui facilite l'évaluation de plusieurs tests et de leur efficacité au fil du temps.

Fonction de sauvegarde des paramètres

Pour optimiser l'efficacité des tests, le Testeur de résistance d'étanchéité comprend une fonction d'enregistrement des paramètres pour jusqu'à 5 configurations de test différentes. Cela permet aux utilisateurs d'enregistrer des paramètres spécifiques tels que les niveaux de vide et les durées de test, ce qui facilite le basculement entre différents types d'échantillons et conditions de test.

Chambre personnalisable et fonctionnalités optionnelles

La chambre d'essai est fabriquée en acrylique transparent de haute qualité, ce qui permet une observation claire du processus d'essai. Des tailles et des formes de chambre personnalisées sont disponibles pour tester une variété de formats d'emballage. L'unité offre également des fonctionnalités optionnelles telles que :

- Micro-imprimante pour l'identification des échantillons et la documentation des résultats des tests.

- Adaptation linguistique pour les marchés internationaux, garantissant que le testeur est accessible aux utilisateurs de différentes régions.

- Intégration de la pompe à vide pour permettre des niveaux de vide plus élevés pour des scénarios de test plus exigeants.

Avantages de l'équipement de test de résistance des joints

Assurance qualité

Les tests de résistance des joints sont essentiels pour garantir que l'emballage peut résister aux contraintes environnementales, protégeant ainsi le contenu contre les dommages, la contamination ou la détérioration. Ces tests sont essentiels pour les industries alimentaires, médicales et pharmaceutiques, où la sécurité et l'intégrité du produit sont primordiales.

Personnalisation

L'équipement peut accueillir différents types d'emballages, des petits sachets aux grands conteneurs, offrant une flexibilité adaptée à un large éventail d'industries. La possibilité d'enregistrer les paramètres de test pour divers matériaux rend l'équipement adaptable à de multiples scénarios de test.

Rentable et efficace

Avec son interface facile à utiliser, ses fonctionnalités automatisées et ses paramètres personnalisables, le Équipement de test de résistance des joints permet aux entreprises de réaliser des tests de manière efficace sans compromettre la précision. Sa capacité à enregistrer les configurations de test et à générer des résultats cumulatifs optimise le flux de travail, réduisant ainsi le temps et les coûts des tests.

Normes applicables : ASTM D3078 et au-delà

ASTM D3078

Cette méthode standard est largement utilisée dans les industries où l'intégrité des joints d'emballage est essentielle. Elle garantit que l'emballage répond aux normes de performance nécessaires pour éviter les fuites et protéger le contenu de la contamination externe.

ASTM D4991

La norme ASTM D4991 est une autre norme connexe qui se concentre sur les tests d'étanchéité des emballages scellés à l'aide d'une méthode différente (pénétration de colorant ou perte de pression). Cette norme est également utilisée parallèlement à la norme ASTM D3078 pour les tests d'étanchéité complets des emballages.

Pourquoi choisir l'équipement de test de résistance des joints de Cell Instruments ?

Cell Instruments est une marque de confiance dans le secteur des tests de matériaux. Forts de plusieurs années d'expérience dans les tests de matériaux d'emballage et les solutions de tests personnalisées, nous proposons des équipements de haute précision conçus pour répondre aux besoins exigeants de diverses industries. Équipement de test de résistance des joints est conçu pour fournir des résultats fiables, précis et efficaces, aidant les entreprises à garantir l'intégrité de leurs emballages.

Avec la flexibilité de tester différents matériaux d'emballage et la capacité d'enregistrer plusieurs configurations de test, notre équipement est conçu pour rationaliser votre processus de test et améliorer votre contrôle qualité.

Assurer l'intégrité du joint d'emballage est essentiel pour maintenir la sécurité, la qualité et la conformité du produit aux normes de l'industrie. Équipement de test de résistance des joints propose une solution efficace, fiable et personnalisable pour les entreprises qui ont besoin d'une détection de fuites de haute précision. Que vous testiez des emballages alimentaires, des joints d'appareils médicaux ou des contenants pharmaceutiques, notre équipement offre la précision et la cohérence dont vous avez besoin pour garantir que vos produits arrivent sur le marché avec la plus grande qualité.

Rubrique FAQ

- Quelle est la norme ASTM D3078 pour les tests d’intégrité des joints ?

- La norme ASTM D3078 est une méthode de test standard permettant de détecter les fuites dans les emballages scellés à l'aide d'une application sous vide. Elle garantit que l'emballage conserve son intégrité en identifiant les joints faibles qui pourraient entraîner une contamination ou une détérioration.

- Comment fonctionne l’équipement de test de résistance des joints ?

- L'équipement place l'échantillon dans une chambre remplie d'eau, applique un vide et détecte les fuites en observant la formation de bulles dans la chambre si l'étanchéité est compromise.

- Quelles industries utilisent les tests de résistance des joints ?

- Les tests de résistance des joints sont essentiels dans des secteurs tels que l'emballage alimentaire, les produits pharmaceutiques, les dispositifs médicaux, les cosmétiques et les biens de consommation, où l'intégrité des joints est essentielle pour la sécurité des produits.

- Puis-je tester différents matériaux d’emballage avec cet équipement ?

- Oui, l’équipement est polyvalent et peut tester une variété de matériaux d’emballage, y compris les plastiques, le papier et l’aluminium, avec des tailles de chambre et des niveaux de vide personnalisables.

- Quels sont les principaux avantages de l’utilisation de l’équipement de test de résistance des joints de Cell Instruments ?

- Les principaux avantages comprennent une grande précision, des fonctionnalités personnalisables, une utilisation facile avec une interface IHM intuitive et la possibilité d'enregistrer des paramètres de test pour différents types d'emballage.