ASTM F2054

Documents de candidature

ASTM F2054 is used for testing the integrity of flexible package seals, such as those used in food, pharmaceutical, and medical device packaging. The method assesses materials including plastic films, laminates, and other barrier materials.

Processus de test

- Préparation des échantillons: Seal the test package according to standard specifications.

- Montage: Place the sealed package between restraining plates.

- Pressurization: Apply internal air pressure at a controlled rate until the package bursts.

- Mesures: Record the burst pressure and observe the failure location and mode.

Interprétation des résultats du test

- Burst Pressure: The internal pressure at which the package seal fails.

- Failure Mode: Analysis of where and how the failure occurred (e.g., seal failure, material rupture).

- Results indicate the strength and reliability of the package seals under internal pressure conditions.

Importance du test

- Ensures package seals are strong enough to withstand internal pressures encountered during transportation and storage.

- Helps in validating the sealing process and identifying potential weaknesses in package design.

- Critical for maintaining product safety, quality, and shelf life.

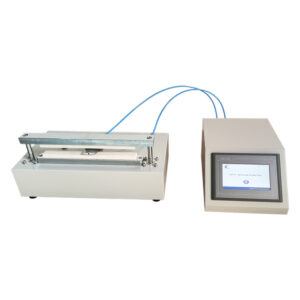

Exigences relatives aux instruments

- Burst tester with internal air pressurization capability.

- Restraining plates to contain the package during pressurization.

- Accurate pressure control and measurement system.

Précautions

- Ensure packages are sealed uniformly and according to standard specifications.

- Calibrate the burst tester regularly to ensure precise measurements.

- Handle packages carefully to avoid pre-test damage or stress.

Voici le seul résultat