¿Qué son las pruebas de penetrabilidad?

ISO 8871-5 Es una norma dentro de la serie ISO 8871, que se centra en las pruebas de penetrabilidad de los componentes elastoméricos de dispositivos inyectables y farmacéuticos.

Introducción de la norma ISO 8871-5 y las pruebas de penetrabilidad

En el ámbito de los productos farmacéuticos, la integridad y el rendimiento de los cierres elastoméricos son fundamentales. Muchos cierres elastoméricos para uso farmacéutico se utilizan junto con agujas de inyección. La fuerza necesaria para penetrar o perforar un cierre de goma es un parámetro importante para evaluar la idoneidad del cierre para el uso previsto. ISO 8871-5 pone de relieve estos requisitos, en particular a través de las pruebas de penetrabilidad.

La definición de penetrabilidad

En el centro de la orientación de la norma ISO 8871-5 se encuentra el parámetro de penetrabilidad—definida sucintamente como la fuerza necesaria para perforar un cierre elastomérico. Esta definición sustenta el enfoque de la norma para garantizar que los cierres utilizados en aplicaciones farmacéuticas cumplan con los criterios de rendimiento esenciales necesarios para su uso previsto.

La importancia de medir la fuerza de penetración

La fuerza de penetración es más que un simple número: es un indicador fundamental de la idoneidad de los tapones para uso médico y farmacéutico. Informa a los fabricantes y usuarios finales sobre la compatibilidad de los cierres elastoméricos con las agujas de inyección, garantizando que la administración de medicamentos no se vea obstaculizada por barreras físicas.

Procedimiento de prueba según la norma ISO 8871-5

Coloque la aguja de inyección y el sello en el soporte del instrumento respectivamente, haga clic en el botón de prueba, el instrumento impulsa la aguja de inyección para perforar verticalmente el sello y registra la fuerza máxima al mismo tiempo. (Nota: Se debe reemplazar una aguja nueva para cada experimento)

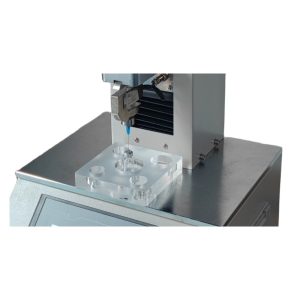

Probador de punción con aguja médica NPT-01

El Probador de penetrabilidad NPT-01 de Cell Instruments permite un proceso de evaluación preciso a través de un procedimiento de prueba diseñado meticulosamente, siguiendo estrictamente las pautas ISO 8871-5:

- Preparación de la muestra y del equipo: Inicialmente, los cierres elastoméricos se acondicionan según lo exige la norma, asegurándose de que se encuentran en el estado adecuado para ser sometidos a los ensayos. El equipo de prueba de penetración se calibra y prepara para recibir las muestras de ensayo, garantizando la máxima precisión.

- Colocación del cierre: Luego, se coloca un cierre de forma segura dentro de la plataforma de prueba del probador NPT-01, posicionado para alinearse con el elemento penetrante, generalmente una aguja o sonda especificada por la norma ISO.

- Medición de la fuerza de penetración: el comprobador NPT-01 ejecuta la prueba de penetración haciendo pasar la aguja a través del cierre a una velocidad controlada. La fuerza ejercida se registra con precisión, lo que ofrece datos valiosos sobre la capacidad de penetración del material.

- Registro y análisis de datos: una vez finalizada la prueba, el comprobador de penetrabilidad registra automáticamente las mediciones de fuerza. Estos resultados se pueden analizar para garantizar la conformidad con los requisitos de la norma ISO 8871-5 y las normas de calidad internas.

- Repetibilidad y confiabilidad: el comprobador NPT-01 está diseñado para lograr repetibilidad, lo que permite probar numerosos cierres en condiciones idénticas. Esta repetibilidad es crucial para obtener datos estadísticos confiables, que a su vez informan los procesos de control de calidad y las certificaciones de cumplimiento.

La inclusión de la penetrabilidad, definida como la fuerza necesaria para perforar un cierre elastomérico, en las normas ISO 8871-5 subraya la precisión con la que las industrias farmacéutica y de dispositivos médicos deben evaluar sus componentes. Este enfoque en las pruebas de penetrabilidad garantiza que los productos resultantes no solo cumplan con las normas de seguridad globales, sino que también mejoren la atención al paciente al garantizar una administración perfecta de los medicamentos.

Artículo relacionado

3 razones para probar la resistencia a la punción con agujas