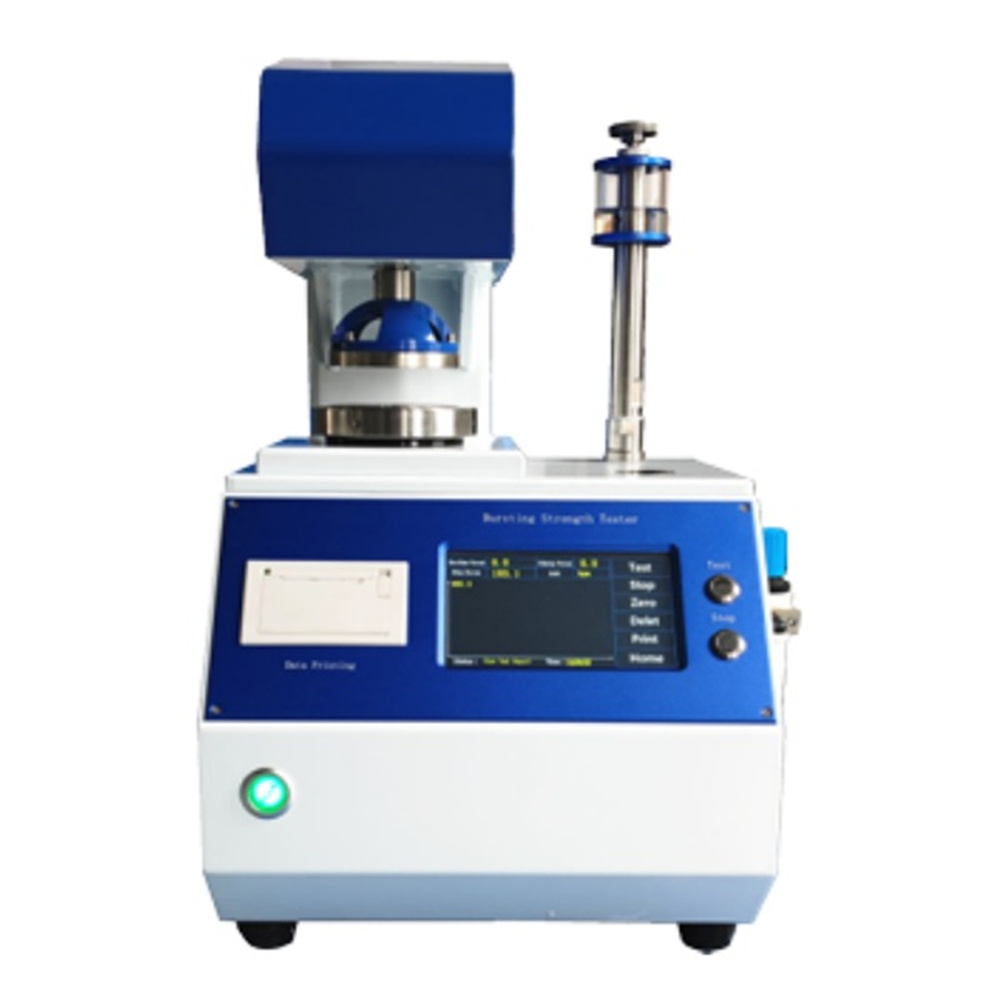

El Comprobador de resistencia al estallido es una herramienta esencial para evaluar la integridad estructural y la durabilidad de los materiales de papel y cartón. Diseñado para evaluar la fuerza máxima que estos materiales pueden soportar antes de romperse, este comprobador se utiliza ampliamente en entornos de embalaje, fabricación y control de calidad. Con aplicaciones que van desde papel liviano hasta cartón resistente, el Comprobador de resistencia al estallido garantiza que los materiales cumplan con estándares rigurosos de rendimiento bajo estrés, lo que lo hace indispensable en industrias donde la resistencia y la durabilidad son primordiales.

Aplicaciones del comprobador de resistencia al estallido

La prueba de resistencia al estallido mide la capacidad de un material para resistir la rotura o el estallido cuando se lo somete a fuerzas externas. Esta cualidad es fundamental para Papel, cartón y materiales de embalaje, particularmente en el contexto de Envío y almacenamientoAl identificar los puntos débiles antes de utilizar los materiales, las empresas pueden evitar daños costosos y garantizar un transporte seguro de los productos. Para los fabricantes, esta prueba proporciona información sobre la calidad del material y sirve de base para el diseño de los embalajes, lo que permite mejorar la durabilidad y reducir el riesgo de daños durante el transporte.

Características principales del comprobador de resistencia al estallido

- Prueba de presión hidráulica: El probador utiliza presión hidráulica para aplicar fuerza a la muestra de prueba, lo que permite una medición altamente precisa de la resistencia al estallido.

- Amplia gama de pruebas: Puede probar un amplio espectro de materiales, desde papeles livianos hasta tableros de fibra sólidos, con resistencias al estallido que varían desde 70 kPa a 5500 kPa.

- Precisión y confiabilidad: Equipado con sensores de presión avanzados, el probador de resistencia al estallido ofrece resultados confiables y repetibles, lo que garantiza una alta precisión en el control de calidad.

Comprobador de rotura de placas: cómo garantizar la resistencia estructural de las placas

El Comprobador de rotura de placa BNP-01 Está diseñado específicamente para probar materiales de placa como Tablero de fibra corrugado y macizoCapaz de medir materiales con resistencias al estallido dentro del rango de 350 kPa a 5500 kPaEste comprobador satisface las exigentes necesidades de los sectores del embalaje y el transporte. Al evaluar la resiliencia del material, permite a los fabricantes garantizar que sus materiales de embalaje puedan soportar las presiones a las que se enfrentan durante la manipulación y el envío. Este comprobador cumple con los principales estándares de la industria, entre los que se incluyen:

- ISO 2759: Reconocida internacionalmente para evaluar la resistencia de los tableros, la norma ISO 2759 establece pautas para evaluar la resistencia al estallido en materiales de tableros, garantizando el cumplimiento de la calidad global.

- TAPPI T810 y TAPPI T807: Estas normas cubren pruebas de estallido para tableros de fibra y cartón corrugado, lo que permite una calidad constante en todos los lotes y garantiza que los materiales de embalaje sean seguros para el transporte.

Comprobador de rotura de papel: optimizado para materiales ligeros

Para aplicaciones en papel, el Probador de rotura de papel ZNP-01 es la elección ideal, ya que prueba materiales con resistencias al estallido que van desde 70 kPa a 1400 kPaEste comprobador es adecuado para materiales más livianos, como papel y cartón fino, y es fundamental en aplicaciones donde la flexibilidad del material es crucial. El ZNP-01 cumple con estándares como:

- ISO 2758: Esta norma regula las pruebas de resistencia al estallido de materiales de papel, garantizando que los resultados cumplan con los puntos de referencia internacionales.

- TAPPI T403 y ASTM D774: Ambas normas describen métodos para evaluar la resistencia del papel, y la norma ASTM D774 se centra en papeles livianos y de alta resiliencia.

Estas normas garantizan que los materiales utilizados en aplicaciones de embalaje e impresión cumplan con la durabilidad requerida para la seguridad del producto y el aseguramiento de la calidad.

Principio de prueba

La prueba de resistencia al estallido implica colocar una muestra sobre un diafragma elástico circular que está sujeto rígidamente en sus bordes pero que puede abultarse en el centro. El fluido hidráulico se bombea a un caudal constante.El diafragma se infla hasta que la muestra de prueba se rompe. El probador registra la presión máxima alcanzada en el momento de la ruptura, lo que indica la fuerza explosivaEste método de prueba es muy preciso y permite a los fabricantes evaluar de forma consistente la resistencia y la calidad de diversos materiales.

Beneficios de utilizar un comprobador de resistencia al estallido

- Garantía de calidad para embalajes: El probador garantiza que los materiales de embalaje puedan soportar las tensiones del envío y la manipulación, reduciendo el riesgo de daños.

- Estándares de producción consistentes: Con pruebas regulares, los fabricantes pueden mantener una calidad uniforme y abordar rápidamente cualquier problema con el rendimiento del material.

- Adaptabilidad entre industrias: Este comprobador es adecuado para una amplia gama de sectores, incluidos Dispositivos médicos, electrónica, textiles, embalajes y alimentos., donde los materiales duraderos son un requisito crítico.

Preguntas frecuentes (FAQ)

- ¿Cuál es el propósito de una prueba de resistencia al estallido?

Esta prueba evalúa la durabilidad de los materiales de papel y cartón determinando la fuerza máxima que pueden resistir antes de romperse. Es esencial para el control de calidad en la fabricación de envases y materiales. - ¿Cómo mide el comprobador de resistencia al estallido la resistencia del material?

El probador aplica presión hidráulica a la muestra hasta que se rompe y la presión máxima se registra como resistencia al estallido del material. - ¿Qué tipos de materiales se pueden probar?

Este probador puede evaluar una amplia gama de materiales, incluido papel liviano, cartón grueso, cartón corrugado y tableros de fibra. - ¿Por qué es importante la norma ISO 2759 en las pruebas de resistencia al estallido?

ISO 2759 es un estándar global que garantiza que los materiales cumplan con parámetros de calidad consistentes, lo cual es fundamental para los fabricantes y proveedores internacionales. - ¿Con qué frecuencia los materiales de embalaje deben someterse a pruebas de resistencia al estallido?

Se recomienda realizar pruebas periódicas, especialmente cuando se producen cambios en el abastecimiento de materiales o en los procesos de producción, para mantener estándares de calidad confiables.