1. Introduction to the Film Free Shrink Tester

El Film Free Shrink Tester is an advanced instrument designed to measure the shrinkage properties of plastic films when exposed to heat. This device plays a crucial role in ensuring the quality and performance of materials across various industries, including packaging, food, medical, and pharmaceuticals. By assessing the heat shrinkage of films, manufacturers can optimize their products for durability and effectiveness, meeting both industry standards and consumer expectations.

2. Product Features

(1) Technical Specifications

| Sample Size | ≤160 mm x 160 mm |

| Temperature Range | Ambient ~ 200°C |

| Accuracy | ±0.3°C |

| Dimension | 37*44*28 LWH cm |

| Power Supply | 220V 50Hz |

(2) Reliable Instrument

Accuracy and Reliability

The Film Free Shrink Tester offers unparalleled accuracy and reliability. With its high-precision temperature control system, it ensures that the testing conditions remain consistent, yielding repeatable results every time. This precision is critical for maintaining the integrity of the test and ensuring that the data collected is reliable and actionable.

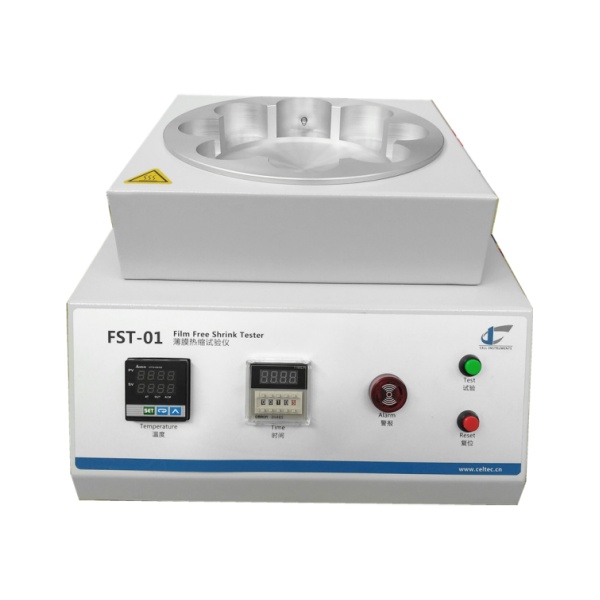

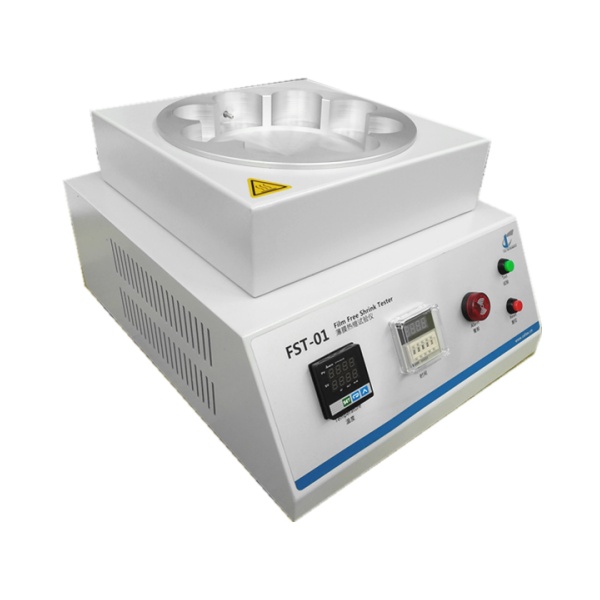

User-Friendly Interface

Designed with ease of use in mind, the Film Free Shrink Tester features an intuitive control panel that simplifies the testing process. The digital display provides clear and concise data logging, making it easy for operators to monitor and record test results. This user-friendly interface reduces the learning curve and increases efficiency in the testing process.

(3) Comprehensive Service – Customization Options

Tailored Solutions for Specific Testing Needs

At Cell Instruments, we understand that different industries have unique testing requirements. Therefore, we offer customized solutions to meet specific needs. Whether it’s adapting the tester for particular types of films or integrating it with existing automated systems, our team can modify the instrument to fit your exact specifications.

Integration with Automated Systems

Our Film Free Shrink Tester can be seamlessly integrated into automated testing systems, enhancing productivity and accuracy. This integration allows for continuous testing and monitoring, which is essential for high-volume production environments.

3. Testing Methods

(1) Overview of the Film Free Shrink Test

Purpose of the Test

The primary purpose of the film free shrink test is to determine how plastic films respond to heat. This test is crucial for understanding the thermal properties of materials, which can impact their performance in real-world applications.

Types of Films Tested

The Film Free Shrink Tester is suitable for a wide range of films, including packaging materials, food packaging films, medical device packaging, pharmaceutical packaging, adhesive films, and textiles. Each type of film has specific characteristics that need to be evaluated to ensure optimal performance.

(2) ASTM D2732 Standard

Description of the Standard

ASTM D2732 is a standardized test method used to measure the free shrinkage of plastic films when exposed to a specified temperature. This standard provides a consistent framework for conducting the test, ensuring that results are comparable across different laboratories and applications.

Test Procedure Outline

Sample Preparation

Samples are cut to a precise size and shape, typically squares or rectangles. Proper preparation is essential to ensure that the results are accurate and reflective of the material’s properties.

Testing Conditions

The test involves heating the samples to a predetermined temperature. The Film Free Shrink Tester’s precise temperature control ensures that the samples are exposed to the exact conditions required by ASTM D2732.

Measurement and Analysis

After heating, the samples are measured to determine the extent of shrinkage. The dimensions before and after the test are compared to calculate the percentage of shrinkage. This data provides insights into the film’s thermal behavior and suitability for specific applications.

4. Industry Applications

The Film Free Shrink Tester is essential for various industries, each with unique requirements for material performance.

(1) Packaging Materials

In the packaging industry, the film shrinkage test helps in designing materials that offer optimal protection and stability. Understanding how films respond to heat ensures that packaging maintains its integrity during processing and storage.

(2) Food Packaging Films

For food packaging, maintaining the quality and safety of the product is paramount. The heat shrinkage test ensures that films used in food packaging are durable and can withstand the conditions they will encounter.

(3) Medical Device Packaging

Medical device packaging requires materials that are both protective and sterile. The film shrinkage test helps in selecting films that meet these stringent requirements, ensuring the safety and effectiveness of medical products.

(4) Pharmaceutical Packaging

Pharmaceutical packaging needs to protect products from contamination and degradation. The shrinkage test ensures that films used in this industry provide the necessary barrier properties.

(5) Adhesive Films

Adhesive films must maintain their properties under various conditions. The film shrinkage test helps in evaluating their performance, ensuring they adhere properly and maintain their effectiveness.

(6) Textiles and Others

In textiles and other industries, understanding the shrinkage properties of films can impact the durability and performance of the final product. This test provides valuable data for improving material selection and product design.

5. Custom Testing Capabilities – Special Testing Requirements

Cell Instruments offers custom testing solutions to meet specific requirements. Whether you need to test unique materials or require specific testing conditions, we can tailor our Film Free Shrink Tester to meet your needs.

FAQ

Q1: What is the purpose of the film free shrink test?

A : The film free shrink test measures the shrinkage properties of plastic films when exposed to heat, providing insights into their thermal behavior and suitability for various applications.

Q2: What types of films can be tested with the Film Free Shrink Tester?

A : The tester is suitable for a wide range of films, including packaging materials, food packaging films, medical device packaging, pharmaceutical packaging, adhesive films, and textiles.

Q3: How does ASTM D2732 standardize the film shrinkage test?

A : ASTM D2732 provides a consistent framework for conducting the test, specifying sample preparation, testing conditions, and measurement procedures to ensure reliable and comparable results.

Q4: Can the Film Free Shrink Tester be customized for specific needs?

A : Yes, Cell Instruments offers customization options to meet specific testing requirements, including tailored solutions and integration with automated systems.

Related Article

ASTM D2732 Shrinkage Films Testing

Film Shrinkage Tester for Plastic Packaging

Thermal Shrinkage Tester for Plastic Film

Film Heat Shrink Tester for Plastic Film